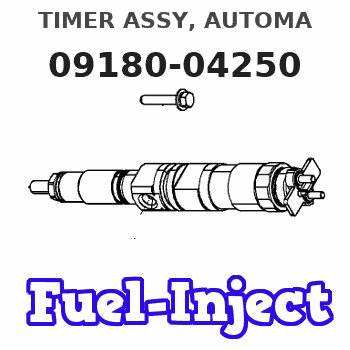

Information timer assy, automa

Rating:

Scheme ###:

| 000. | [01] | 09180-04250 | TIMER ASSY, AUTOMA | |

| 001. | [01] | 09181-12140 | HUB, TIMER | 22516-2070A |

| 002. | [02] | 09183-61460 | WEIGHT SUB-ASSY, T | |

| 003. | [02] | 09189-50180 | CAM, TIMER | 22545-1330A |

| 004. | [02] | 09189-50170 | CAM, TIMER | 22545-1320A |

| 005. | [04] | 94907-10880 | WASHER, SNAP | 22518-1110A |

| 006. | [01] | 09184-01131 | FLANGE, TIMER DRIV | 22513-2420A |

| 006-001. | [01] | 94915-02910 | SEAL, OIL | 22827-1680A |

| 008. | [4C] | 09181-81990 | SPRING, TIMER SUB | |

| 008. | [4C] | 09181-81980 | SPRING, TIMER SUB | |

| 009. | [02] | 09188-40140 | SUPPORT, TIMER SPR | 22517-1590A |

| 010. | [01] | 09187-00190 | COVER SUB-ASSY, TI | 22501-1210A |

| 010. | [01] | 09187-00240 | COVER SUB-ASSY, TI | |

| 010-001. | [01] | 94915-02920 | SEAL, OIL | 22827-1690A |

| 011. | [04] | 09181-70570 | SEAT | 22517-1581A |

| 012. | [04] | 09181-70440 | SEAT | 22517-1770A |

| 013. | [02] | 09186-20010 | SCREW, TIMER HUB | 22865-1270A |

| 014. | [01] | 09186-70360 | PLATE, TIMER DRIVI | 22513-2670A |

| 015. | [02] | 09188-20140 | ROLLER, TIMER | 22522-1090A |

| 016. | [02] | 94901-81020 | WASHER, COPPER PLA | 22867-1500A |

| 017. | [4C] | 94901-39530 | WASHER, PLATE, SK | 22885-7880A |

| 017. | [4C] | 94901-39520 | WASHER, PLATE, SK | 22885-7890A |

| 017. | [4C] | 94901-39510 | WASHER, PLATE, SK | 22885-7860A |

| 017. | [4C] | 94901-39500 | WASHER, PLATE, SK | 22885-7850A |

| 017. | [4C] | 94901-39490 | WASHER, PLATE, SK | 22885-7840A |

| 017. | [4C] | 94901-39480 | WASHER, PLATE, SK | 22885-7830A |

| 017. | [4C] | 94901-38920 | WASHER, PLATE, SK | 22885-7350A |

| 017. | [4C] | 94901-38910 | WASHER, PLATE, SK | 22885-7340A |

| 017. | [4C] | 94901-38200 | WASHER, PLATE, SK | 22885-5890A |

| 017. | [4C] | 94901-38190 | WASHER, PLATE, SK | 22885-5880A |

| 017. | [4C] | 94901-38180 | WASHER, PLATE, SK | 22885-5870A |

| 018. | [01] | 94914-03950 | O-RING | 22817-1930A |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-04250 | TIMER ASSY, AUTOMA | ||

| S2251-03120-A | HINO | TIMER ASSY, AUTOMA |

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.This form is to be used and filled out in any case that a DEF pump or DEF back flow valve is being replaced.The DEF pump troubleshooting return form needs to be completed and included with failed part returns documenting what was found that led to DEF pump or back flow valve replacement. Attach the photos of DEF pump and mount area and any photos requested as per the tables along with a Product Status Report to the Service Information Management System (SIMS) claim.Safety Section

Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards, including human factors that can affect safety. This person should also have the necessary training, skills, and tools to perform these functions properly.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Climbing equipment may be required to access this service point. Refer to the Operation and Maintenance Manual, "Mounting and Dismounting" topic for safety information.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.This form is to be used and filled out in any case that a DEF pump or DEF back flow valve is being replaced.The DEF pump troubleshooting return form needs to be completed and included with failed part returns documenting what was found that led to DEF pump or back flow valve replacement. Attach the photos of DEF pump and mount area and any photos requested as per the tables along with a Product Status Report to the Service Information Management System (SIMS) claim.Safety Section

Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards, including human factors that can affect safety. This person should also have the necessary training, skills, and tools to perform these functions properly.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Climbing equipment may be required to access this service point. Refer to the Operation and Maintenance Manual, "Mounting and Dismounting" topic for safety information.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may