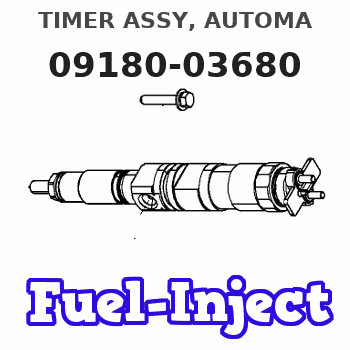

Information timer assy, automa

Rating:

KIT List:

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

Scheme ###:

| 000. | [01] | 09180-03680 | TIMER ASSY, AUTOMA | ME736796 |

| 001. | [01] | 09181-11820 | HUB, TIMER | ME736549 |

| 002. | [02] | 09183-61090 | WEIGHT SUB-ASSY, T | ME736811 |

| 003. | [02] | 09189-50340 | CAM, TIMER | ME736494 |

| 004. | [02] | 09189-50330 | CAM, TIMER | ME736495 |

| 005. | [04] | 94907-10880 | WASHER, SNAP | ME703750 |

| 006. | [01] | 09185-00390 | GEAR, DRIVE | ME736089 |

| 007. | [8C] | 94901-39080 | WASHER, PLATE, SK | ME736095 |

| 007. | [8C] | 94901-39070 | WASHER, PLATE, SK | ME736094 |

| 007. | [8C] | 94901-39060 | WASHER, PLATE, SK | ME736093 |

| 007. | [8C] | 94901-39050 | WASHER, PLATE, SK | ME736092 |

| 007. | [8C] | 94901-39040 | WASHER, PLATE, SK | ME736091 |

| 007. | [8C] | 94901-39030 | WASHER, PLATE, SK | ME736090 |

| 011. | [04] | 09181-81240 | SPRING, TIMER SUB | ME736812 |

| 014. | [02] | 09188-40130 | SUPPORT, TIMER SPR | ME736098 |

| 015. | [04] | 09181-70400 | SEAT | ME736100 |

| 016. | [04] | 09181-70440 | SEAT | ME736496 |

| 017. | [01] | 90557-45000 | RING, SHAFT SNAP | ME736101 |

| 018. | [01] | 90557-35000 | RING, SHAFT SNAP | ME703758 |

| 019. | [01] | 09185-60461 | COVER, TIMER | ME736102 |

| 020. | [02] | 09188-20070 | ROLLER, TIMER | ME736802 |

| 021. | [2C] | 94901-38070 | WASHER, PLATE, SK | ME703767 |

| 021. | [2C] | 94901-38060 | WASHER, PLATE, SK | ME703766 |

| 021. | [2C] | 94901-38050 | WASHER, PLATE, SK | ME703765 |

| 021. | [2C] | 94901-38040 | WASHER, PLATE, SK | ME703764 |

| 021. | [2C] | 94901-38030 | WASHER, PLATE, SK | ME703763 |

| 021. | [2C] | 94901-38020 | WASHER, PLATE, SK | ME703762 |

| 022. | [2C] | 94901-38970 | WASHER, PLATE, SK | ME736103 |

| 022. | [2C] | 94901-38980 | WASHER, PLATE, SK | ME736104 |

| 022. | [2C] | 94901-38990 | WASHER, PLATE, SK | ME736105 |

| 022. | [2C] | 94901-39000 | WASHER, PLATE, SK | ME736106 |

| 022. | [2C] | 94901-39010 | WASHER, PLATE, SK | ME736107 |

| 022. | [2C] | 94901-39020 | WASHER, PLATE, SK | ME736108 |

Include in #3:

09180-03680

as TIMER ASSY, AUTOMA

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-03680 | ME736796 | TIMER ASSY, AUTOMA | |

| ME736796 | MITSUBISHI | TIMER ASSY, AUTOMA |

Information:

Introduction

The problem that is identified below has a known solution. Use the solution that is identified below.Problem

Incorrect wiring on heated diesel exhaust fluid (DEF) lines may reduce thawing performance in colder climates on the machines listed above. Incorrect wiring may also cause the following codes:

E1309Low Aftertreatment #1 SCR Catalyst Conversion Efficiency

3821-7Aftertreatment #1 Diesel Exhause Fluid Dosing Calve Actuator: Not Responding Properly

E1370Aftertreatment #1 Diesel Exhaust Fluid Dosing Unit Loss of Prime

E1389Aftertreatment #1 SCR Operator InducementSolution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Table 1

Required Parts

Qty Part Number Part Name

2 3S-2093 Cable Strap

Table 2

Required Pin Changes for 374-8331 Connector Plug As

Circuit Wire Color New Pin Location Former Pin Location

U940 Gray 23 15

U941 Pink 24 16

U942 Green 39 23

U937 White 73 24

U938 Blue 15 39

U939 Orange 16 73 Procedure to Change Connector Plug Assembly Pins

Turn the engine disconnect switch to the OFF position.

Illustration 1 g06613177

Back of ECM

(A) Center allen head screw

Locate the ECM connector and loosen the center allen head screw (A).

Illustration 2 g06613182

ECM connector removed from ECM

Disengage the ECM connector from the ECM.

Illustration 3 g06613186

Area to mark with paint

(B) Gray locking wedge

(D) Connector cover

Paint a mark on the gray locking wedge (B) and the connector to ensure correct orientation when reassembled.Note: Paint assists identification of pin positions when removing and relocating wire circuits.

Illustration 4 g06613187

View of back of Connector cover (D)

( C) Cable straps

(D) Connector cover

Illustration 5 g06613189

Connector cover (D) removed

Cut cable straps (C) securing the harness wires to the connector cover (D).Remove connector cover (D).

Illustration 6 g06613192

Gray locking wedge removed from ECM connector

Remove gray locking wedge from 86-pin connector to provide access to release the DT Pins.Note: Circuit U937 to be removed from pin location number 24 and transferred to pin location 73.Note: Cloth tape will need to be removed to the split in the harness main bundle.Note: The U937 wire can then be routed into the opposite branch to gain enough free length to make the connection.Note: The U939 wire removed from pin location 73 has adequate length to be loaded into location 16.

Transfer and relocate the wires as detailed in Table 2.

Reinstall the locking wedge (B) when all wires have been transferred and relocated.

Illustration 7 g06613197

View of back of ECM connector with connector cover (D) removed

Apply cloth tape to both wire branches from the main bundle of wires up the branches to the harness strain relief strap location.

The problem that is identified below has a known solution. Use the solution that is identified below.Problem

Incorrect wiring on heated diesel exhaust fluid (DEF) lines may reduce thawing performance in colder climates on the machines listed above. Incorrect wiring may also cause the following codes:

E1309Low Aftertreatment #1 SCR Catalyst Conversion Efficiency

3821-7Aftertreatment #1 Diesel Exhause Fluid Dosing Calve Actuator: Not Responding Properly

E1370Aftertreatment #1 Diesel Exhaust Fluid Dosing Unit Loss of Prime

E1389Aftertreatment #1 SCR Operator InducementSolution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Table 1

Required Parts

Qty Part Number Part Name

2 3S-2093 Cable Strap

Table 2

Required Pin Changes for 374-8331 Connector Plug As

Circuit Wire Color New Pin Location Former Pin Location

U940 Gray 23 15

U941 Pink 24 16

U942 Green 39 23

U937 White 73 24

U938 Blue 15 39

U939 Orange 16 73 Procedure to Change Connector Plug Assembly Pins

Turn the engine disconnect switch to the OFF position.

Illustration 1 g06613177

Back of ECM

(A) Center allen head screw

Locate the ECM connector and loosen the center allen head screw (A).

Illustration 2 g06613182

ECM connector removed from ECM

Disengage the ECM connector from the ECM.

Illustration 3 g06613186

Area to mark with paint

(B) Gray locking wedge

(D) Connector cover

Paint a mark on the gray locking wedge (B) and the connector to ensure correct orientation when reassembled.Note: Paint assists identification of pin positions when removing and relocating wire circuits.

Illustration 4 g06613187

View of back of Connector cover (D)

( C) Cable straps

(D) Connector cover

Illustration 5 g06613189

Connector cover (D) removed

Cut cable straps (C) securing the harness wires to the connector cover (D).Remove connector cover (D).

Illustration 6 g06613192

Gray locking wedge removed from ECM connector

Remove gray locking wedge from 86-pin connector to provide access to release the DT Pins.Note: Circuit U937 to be removed from pin location number 24 and transferred to pin location 73.Note: Cloth tape will need to be removed to the split in the harness main bundle.Note: The U937 wire can then be routed into the opposite branch to gain enough free length to make the connection.Note: The U939 wire removed from pin location 73 has adequate length to be loaded into location 16.

Transfer and relocate the wires as detailed in Table 2.

Reinstall the locking wedge (B) when all wires have been transferred and relocated.

Illustration 7 g06613197

View of back of ECM connector with connector cover (D) removed

Apply cloth tape to both wire branches from the main bundle of wires up the branches to the harness strain relief strap location.