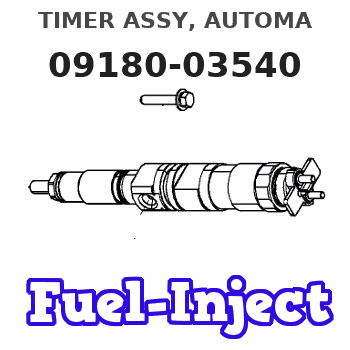

Information timer assy, automa

Rating:

KIT List:

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

| Timer assy, automa | No Application |

Scheme ###:

| 000. | [01] | 09180-03540 | TIMER ASSY, AUTOMA | |

| 001. | [01] | 09181-11770 | HUB, TIMER | 22516-1910A |

| 002. | [02] | 09183-60990 | WEIGHT SUB-ASSY, T | 22514-3390A |

| 003. | [02] | 09189-50350 | CAM, TIMER | 22545-1400A |

| 004. | [02] | 09189-50360 | CAM, TIMER | 22545-1410A |

| 005. | [04] | 94907-10880 | WASHER, SNAP | 22518-1110A |

| 006. | [01] | 09184-01140 | FLANGE, TIMER DRIV | 22513-2410A |

| 006-001. | [01] | 94915-02910 | SEAL, OIL | 22827-1680A |

| 007. | [04] | 09181-92970 | SPRING, TIMER | 22515-5280A |

| 008. | [4C] | 09181-81080 | SPRING, TIMER SUB | 22515-5270A |

| 008. | [4C] | 09181-81170 | SPRING, TIMER SUB | |

| 008. | [4C] | 09181-81180 | SPRING, TIMER SUB | |

| 009. | [02] | 09188-40140 | SUPPORT, TIMER SPR | 22517-1590A |

| 010. | [01] | 09187-00190 | COVER SUB-ASSY, TI | 22501-1210A |

| 010. | [01] | 09187-00240 | COVER SUB-ASSY, TI | |

| 010-001. | [01] | 94915-02920 | SEAL, OIL | 22827-1690A |

| 011. | [04] | 09181-70490 | SEAT | 22517-1570A |

| 012. | [04] | 09181-70500 | SEAT | 22517-1580A |

| 013. | [02] | 09186-20010 | SCREW, TIMER HUB | 22865-1270A |

| 014. | [01] | 09186-70240 | PLATE, TIMER DRIVI | 22513-2110A |

| 015. | [02] | 09188-20030 | ROLLER, TIMER | 22522-1040A |

| 016. | [02] | 94901-81020 | WASHER, COPPER PLA | 22847-1300A |

| 017. | [4C] | 94901-39530 | WASHER, PLATE, SK | 22885-7880A |

| 017. | [4C] | 94901-39520 | WASHER, PLATE, SK | 22885-7890A |

| 017. | [4C] | 94901-39510 | WASHER, PLATE, SK | 22885-7860A |

| 017. | [4C] | 94901-39500 | WASHER, PLATE, SK | 22885-7850A |

| 017. | [4C] | 94901-39490 | WASHER, PLATE, SK | 22885-7840A |

| 017. | [4C] | 94901-39480 | WASHER, PLATE, SK | 22885-7830A |

| 017. | [4C] | 94901-38920 | WASHER, PLATE, SK | |

| 017. | [4C] | 94901-38910 | WASHER, PLATE, SK | |

| 017. | [4C] | 94901-38200 | WASHER, PLATE, SK | 22885-5890A |

| 017. | [4C] | 94901-38190 | WASHER, PLATE, SK | 22885-5880A |

| 017. | [4C] | 94901-38180 | WASHER, PLATE, SK | 22885-5870A |

| 018. | [01] | 94914-03950 | O-RING | 22817-1930A |

Include in #3:

09180-03540

as TIMER ASSY, AUTOMA

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-03540 | TIMER ASSY, AUTOMA |

Information:

Introduction

This Special Instruction contains the steps to remove a portion of a gusset inside the enclosure, near the DEF tank wire harness. The interference between the gusset and the wire harness may damage the wire harness. An improvement is already in production for machines after the listed range of Serial Numbers.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Caterpillar Channel 1 Videos

For supplemental information on this procedure, refer to the following video. The previous training has been replaced with the video below.Note: A CWS login is required to access Caterpillar Channel 1. Scan the QR code below with a QR enabled device or copy the link that follows.

Illustration 1 g06306276https://channel1.mediaspace.kaltura.com/media/Introduction+to+Visualization+Service+Procedures+%28VSP%29/1_92vjr92v

Safety Section

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Climbing equipment may be required to access this service point. Refer to the Operation and Maintenance Manual, "Mounting and Dismounting" topic for safety information.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Do not operate the machine if any guards or covers are missing or inadequately secured. Personnel could be seriously injured or machine damage may occur.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

General Information

Graphic Color Description

Color-coding of targeted components, or sections of a part, is used to communicate a

This Special Instruction contains the steps to remove a portion of a gusset inside the enclosure, near the DEF tank wire harness. The interference between the gusset and the wire harness may damage the wire harness. An improvement is already in production for machines after the listed range of Serial Numbers.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Caterpillar Channel 1 Videos

For supplemental information on this procedure, refer to the following video. The previous training has been replaced with the video below.Note: A CWS login is required to access Caterpillar Channel 1. Scan the QR code below with a QR enabled device or copy the link that follows.

Illustration 1 g06306276https://channel1.mediaspace.kaltura.com/media/Introduction+to+Visualization+Service+Procedures+%28VSP%29/1_92vjr92v

Safety Section

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Climbing equipment may be required to access this service point. Refer to the Operation and Maintenance Manual, "Mounting and Dismounting" topic for safety information.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Do not operate the machine if any guards or covers are missing or inadequately secured. Personnel could be seriously injured or machine damage may occur.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

General Information

Graphic Color Description

Color-coding of targeted components, or sections of a part, is used to communicate a