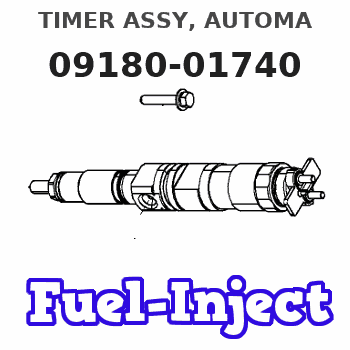

Information timer assy, automa

Rating:

KIT List:

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

Scheme ###:

| 000. | [01] | 09180-01740 | TIMER ASSY, AUTOMA | |

| 001. | [01] | 09181-01020 | HUB ASSY, TIMER | 22516-1330A |

| 002. | [02] | 09181-90990 | SPRING, TIMER | 22515-1310A |

| 003. | [2C] | 94901-33760 | WASHER, PLATE, SK | 22881-2350A |

| 003. | [2C] | 94901-33770 | WASHER, PLATE, SK | 22881-2360A |

| 003. | [2C] | 94901-33780 | WASHER, PLATE, SK | 22881-2370A |

| 003. | [2C] | 94901-33790 | WASHER, PLATE, SK | 22881-2380A |

| 003. | [2C] | 94901-33800 | WASHER, PLATE, SK | 22881-2390A |

| 004. | [01] | 94914-00010 | O-RING | 22817-1170A |

| 005. | [01] | 09183-70361 | WEIGHT, TIMER | 22514-1400A |

| 006. | [01] | 09184-00780 | FLANGE, TIMER DRIV | 22513-1680A |

| 006. | [01] | 09184-00950 | FLANGE, TIMER DRIV | |

| 007. | [01] | 94915-02080 | SEAL, OIL | 22827-1230A |

| 008. | [01] | 94915-00070 | SEAL, OIL | 22827-1210A |

| 009. | [01] | 09187-00130 | COVER SUB-ASSY, TI | 22512-1290A |

| 010. | [02] | 94901-81020 | WASHER, COPPER PLA | 22867-1500A |

| 011. | [02] | 09186-20010 | SCREW, TIMER HUB | 22865-1270A |

Include in #3:

09180-01740

as TIMER ASSY, AUTOMA

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-01740 | TIMER ASSY, AUTOMA |

Information:

(3) Torque for locknut for valve adjustment screw ... 30 4 N m (22 3 lb ft)(4) Torque for locknut for bridge adjustment screw ... 30 4 N m (22 3 lb ft)(5) Valve lash: Intake valves ... 0.38 mm (.015 in)Exhaust valves ... 0.76 mm (.030 in)(6) Height to top of dowel ... 53.3 0.5 mm (2.10 .02 in)(7) Diameter of dowel ... 11.008 0.003 mm (.4334 .0001 in) Bore in bridge for dowel ... 11.13 0.05 mm (.438 .002 in)Bore in head for dowel ... 10.968 0.020 mm (.4318 .0008 in)(8) Diameter of valve lifter ... 27.896 0.013 mm (1.0983 .0005 in) Bore in block for valve lifter ... 27.953 0.019 mm (1.1005 .0008 in) See Guideline For Reusable Parts; Salvage Of Lifter Bores In 3400 Family Engines, Form No. SEBF8069 for the procedure, tooling and specifications needed to install 4W4588 Sleeves for salvage of the lifter bores in the cylinder block.(9) Guide springs must not be used again. Always install new guide springs. (10) 2N7229 Spring: Length under test force ... 74.2 mm (2.92 in)Test force ... 45 to 53 N (10 to 12 lb)Free length after test ... 114.3 mm (4.50 in)Outside diameter ... 29.7 mm (1.17 in)(11) Dowel length above top surface of rocker shaft support to be ... 12.7 1.0 mm (.50 .04 in)(12) Clearance for rocker arms (both ends) ... 0.30 to 1.40 mm (.012 to .055 in)(13) Use 2N7228 Washer as needed to get clearance (12). There must be a minimum of one 2N7228 Washer at each end of the rocker arm shaft. The bridge should be checked and/or adjusted each time the valves are adjusted. To check for wear use a dial indicator to measure the amount of wear on the bridge seat. Make sure the contact point on the dial indicator is small enough in diameter to get an accurate measurement. (A) Minimum dimension after reconditioning ... 16.51 mm (.650 in)(B) Allowable wear before reconditioning ... 0.13 mm (.005 in).Inspect the bridge seats for wear. Use the bridge again if the wear is 0.13 mm (.005 in) or less. When the wear seat is worn more than the allowable limit, the worn surface of the seat can be ground flat. The maximum amount of material that can be removed is 0.38 mm (.015 in). If the seat cannot be made flat, replace the bridge. Reconditioning of the wear seat can only be done once.