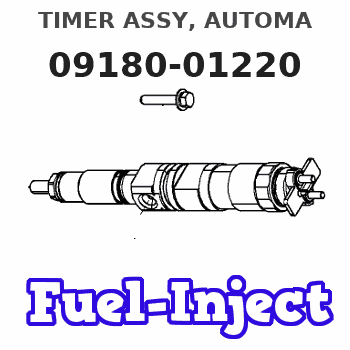

Information timer assy, automa

Rating:

Scheme ###:

| 000. | [01] | 09180-01220 | TIMER ASSY, AUTOMA | 22510-1220 |

| 000. | [01] | 09180-01221 | TIMER ASSY, AUTOMA | S2251-01220 |

| 001. | [01] | 09181-00771 | HUB ASSY, TIMER | 6 306 1404 00 |

| 002. | [02] | 09181-91000 | SPRING, TIMER | 22515-1300 |

| 003. | [02] | 09181-80090 | SPRING, TIMER SUB | 22515-1290 |

| 004. | [01] | 94914-00010 | O-RING | 22817-1170A |

| 005. | [02] | 09183-70371 | WEIGHT, TIMER | 22514-2110A |

| 006. | [01] | 09184-00662 | FLANGE, TIMER DRIV | 22513-1220 |

| 007. | [01] | 94915-00080 | SEAL, OIL | 22827-1160A |

| 008. | [01] | 94915-00070 | SEAL, OIL | 22827-1210A |

| 009. | [01] | 09185-60172 | COVER, TIMER | |

| 010. | [02] | 94901-81020 | WASHER, COPPER PLA | 22847-1300A |

| 011. | [02] | 09186-20010 | SCREW, TIMER HUB | 22865-1270A |

| 012. | [2C] | 94901-33960 | WASHER, PLATE, SK | 22885-1030A |

| 012. | [2C] | 94901-32090 | WASHER, PLATE, SK | 22855-1010 |

| 014. | [04] | 09181-70020 | SEAT | 22517-1060 |

| 015. | [3C] | 94901-33800 | WASHER, PLATE, SK | 22885-1880A |

| 015. | [3C] | 94901-33790 | WASHER, PLATE, SK | 22885-1870A |

| 015. | [3C] | 94901-33780 | WASHER, PLATE, SK | 22881-2370A |

| 015. | [3C] | 94901-33770 | WASHER, PLATE, SK | 22881-2360A |

| 015. | [3C] | 94901-33760 | WASHER, PLATE, SK | 22881-2350A |

| 015. | [3C] | 94901-33810 | WASHER, PLATE, SK | 22885-1600A |

Include in #3:

09180-01220

as TIMER ASSY, AUTOMA

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-01220 | 22510-1220 | TIMER ASSY, AUTOMA | |

| 22510-1220A | HINO | TIMER ASSY, AUTOMA | |

| 22510-1220 | HINO | TIMER ASSY, AUTOMA | |

| S2251-01220 | HINO | TIMER ASSY, AUTOMA |

Information:

1. Cold Outside TemperatureWhite smoke is normal in cold temperatures until the engine warms up. There will be less white smoke if No. 1 diesel or blended fuel is used.2. Engine Running Too ColdCheck the water temperature gauge in the cab. If the temperature remains below the minimum value of the gauge after a reasonable warm up time, this could indicate an open thermostat. Remove and test the thermostat. See the topic, Testing The Cooling System, in 3176 Diesel Truck Engine Systems Operation And Testing and Adjusting, Form No. SENR3909.3. Air In Fuel SystemDisconnect the fuel return line at the tank. Place this end of the line in a container of fuel to see if air bubbles are present when the engine is running. If air bubbles are observed, check for loose fittings or line leaks between the fuel tank and fuel transfer pump. If leaks are found, tighten the connections or replace the lines.To remove air from the engine fuel system: With the engine off, loosen the fuel return line fitting at the fuel manifold. Operate the fuel priming pump until the flow of fuel is free of air. Tighten the return line fitting, fasten the priming pump, and start the engine. If the engine still does not run smooth or produces a lot of white smoke, apply 35 kPa (5 psi) of air pressure to the fuel tank to force fuel through the system.

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check the fuel return line for restriction. Replace if plugged.5. Fuel Injection Timing Out Of CalibrationCheck the fuel injection timing calibration and make necessary adjustments. See the topics, Engine Test Procedure Number P-402, [Checking Electronic Injection Timing With The Timing Adapter Tool Group And The ECAP (Electronic Control Analyzer and Programmer)], and Engine Test Procedure Number P-403, [Calibrating Electronic Injection Timing With The Timing Adapter Tool Group And The ECAP (Electronic Control Analyzer and Programmer)], in Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913.6. Valve Adjustment Not CorrectCheck and make any necessary adjustments. See the topic, Valve Clearance Setting, in 3176 Diesel Truck Engine Systems Operation And Testing and Adjusting, Form No. SENR3909. Intake valve clearance is 0.38 mm (.015 in), and exhaust valve clearance is 0.64 mm (.025 in).7. Defective Unit InjectorsA defective unit injector can be found, by running the engine at the rpm where the problem exists, with the use of the Electronic Control Analyzer and Programmer (ECAP) service tool Interactive Diagnostics feature (single cylinder cutout, see Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913) to stop the fuel supply to each cylinder in turn. If a cylinder is found where the cutout makes no difference on the engine performance, that injector should be removed and tested. Drain the fuel supply manifold and remove the injector(s) (see 3176 Diesel Truck Engine Disassembly and Assembly, Form No. SENR3914).Testing of the injectors must be done off of the

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check the fuel return line for restriction. Replace if plugged.5. Fuel Injection Timing Out Of CalibrationCheck the fuel injection timing calibration and make necessary adjustments. See the topics, Engine Test Procedure Number P-402, [Checking Electronic Injection Timing With The Timing Adapter Tool Group And The ECAP (Electronic Control Analyzer and Programmer)], and Engine Test Procedure Number P-403, [Calibrating Electronic Injection Timing With The Timing Adapter Tool Group And The ECAP (Electronic Control Analyzer and Programmer)], in Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913.6. Valve Adjustment Not CorrectCheck and make any necessary adjustments. See the topic, Valve Clearance Setting, in 3176 Diesel Truck Engine Systems Operation And Testing and Adjusting, Form No. SENR3909. Intake valve clearance is 0.38 mm (.015 in), and exhaust valve clearance is 0.64 mm (.025 in).7. Defective Unit InjectorsA defective unit injector can be found, by running the engine at the rpm where the problem exists, with the use of the Electronic Control Analyzer and Programmer (ECAP) service tool Interactive Diagnostics feature (single cylinder cutout, see Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913) to stop the fuel supply to each cylinder in turn. If a cylinder is found where the cutout makes no difference on the engine performance, that injector should be removed and tested. Drain the fuel supply manifold and remove the injector(s) (see 3176 Diesel Truck Engine Disassembly and Assembly, Form No. SENR3914).Testing of the injectors must be done off of the