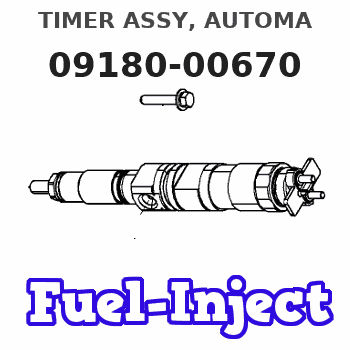

Information timer assy, automa

Rating:

KIT List:

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

| Timer assy, automa | 0918030060 |

Scheme ###:

| 000. | [01] | 09180-00670 | TIMER ASSY, AUTOMA | 22510-1360 |

| 001. | [01] | 09181-00721 | HUB ASSY, TIMER | 22516-1040A |

| 002. | [02] | 09181-90010 | SPRING, TIMER | 6 053 1451 20 |

| 003. | [2C] | 94901-33760 | WASHER, PLATE, SK | 22881-2350A |

| 003. | [2C] | 94901-33770 | WASHER, PLATE, SK | 22881-2360A |

| 003. | [2C] | 94901-33780 | WASHER, PLATE, SK | 22881-2370A |

| 003. | [2C] | 94901-33790 | WASHER, PLATE, SK | 22885-1870A |

| 003. | [2C] | 94901-33800 | WASHER, PLATE, SK | 22885-1880A |

| 004. | [01] | 94914-00010 | O-RING | 22817-1170A |

| 005. | [02] | 09183-70281 | WEIGHT, TIMER | 22514-1030A |

| 006. | [01] | 09184-00432 | FLANGE, TIMER DRIV | 22513-1050 |

| 007. | [01] | 94915-02080 | SEAL, OIL | 22827-1230A |

| 008. | [01] | 94915-00070 | SEAL, OIL | 22827-1210A |

| 009. | [01] | 09187-00130 | COVER SUB-ASSY, TI | 22512-1290A |

| 010. | [02] | 94901-81020 | WASHER, COPPER PLA | 22847-1300A |

| 011. | [02] | 09186-20010 | SCREW, TIMER HUB | 22865-1270A |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-00670 | 22510-1360 | TIMER ASSY, AUTOMA | |

| 22510-1360 | HINO | TIMER ASSY, AUTOMA |

Information:

Mismatched or incorrect fasteners can result in damage or malfunction, or possible injury.Take care to avoid mixing metric dimensioned fasteners and inch dimensioned fasteners.

Exceptions to these torques are given in the Service Manual, if necessary.Prior to installing any hardware, ensure that the components are in near new condition. Bolts and threads must nor be worn or damaged. Threads must not have burrs or nicks. Hardware must be free of rust and corrosion. Clean the hardware with a noncorrosive cleaner. Do not lubricate the fastener threads except with rust preventive. The rust preventive should be applied by the supplier of that component for purposes of shipping and storage. Other applications for lubricating components may also be specified in the Service Manual.For additional torque specifications, refer to SENR3130, Torque Specifications, available from your Caterpillar dealer.Standard Torque for Bolts, Nuts and Taperlock Studs

Torques for Taperlock Studs

Use these standard torque values for all fasteners unless otherwise specified in this manual or in the Service Manual.Torque for Metric Fasteners

Torque for Standard Hose Clamps-Worm Drive Band Type

The chart that follows gives the torques for initial installation of hose clamps on new hose and for reassembly or tightening of hose clamps on existing hose.

Torque for Constant Torque Hose Clamps

A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp. Due to extreme temperature changes, hose will heat set. Heat setting causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The constant torque hose clamp will help prevent these failures. Use a torque wrench for proper installation of the constant torque hose clamp. The constant torque hose clamp is installed correctly under the following conditions: * Screw tip (1) extends 6.35 mm (.250 in) (X) beyond the housing.* The belleville washers are collapsed nearly flat after screw (2) is tightened to a torque of 11 1 N m (98 9 lb in).