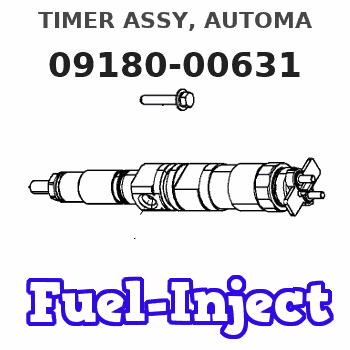

Information timer assy, automa

Rating:

Scheme ###:

| 000. | [01] | 09180-00631 | TIMER ASSY, AUTOMA | |

| 001. | [01] | 09181-00222 | HUB ASSY, TIMER | 22516-1360A |

| 002. | [01] | 09184-00221 | FLANGE, TIMER DRIV | 22513-1430A |

| 003. | [02] | 09183-60081 | WEIGHT SUB-ASSY, T | 22514-1240A |

| 004. | [01] | 09185-60310 | COVER, TIMER | 22512-1010A |

| 005. | [01] | 94915-00980 | SEAL, OIL | 22827-1080A |

| 009. | [02] | 94904-04471 | BOLT, HEXAGON | 22815-2390A |

| 010. | [02] | 09022-20080 | WASHER, FUEL PIPE | 22847-1330A |

| 011. | [04] | 09188-40011 | SUPPORT, TIMER SPR | 22517-1110A |

| 012. | [04] | 09181-90540 | SPRING, TIMER | |

| 013. | [4C] | 94901-34330 | WASHER, PLATE, SK | 9009K-01445 |

| 013. | [4C] | 94901-34210 | WASHER, PLATE, SK | 22885-1690A |

| 013. | [4C] | 94901-34200 | WASHER, PLATE, SK | 22885-1680A |

| 013. | [4C] | 94901-34190 | WASHER, PLATE, SK | 22885-1670A |

| 013. | [4C] | 94901-34180 | WASHER, PLATE, SK | 22885-1660A |

| 013. | [4C] | 94901-34170 | WASHER, PLATE, SK | 22885-1650A |

| 014. | [02] | 09188-30010 | BUSHING, TIMER ROL | 22521-1020 |

| 015. | [02] | 09188-20010 | ROLLER, TIMER | 22522-1010A |

| 016. | [02] | 94901-15070 | WASHER, STEEL PLAT | 22867-1120A |

| 017. | [01] | 09188-50020 | SCREW, TIMER OIL S | 22845-1120A |

| 018. | [01] | 09083-90040 | PACKING | 22847-2410A |

| 018. | [01] | 09083-90020 | PACKING | 22847-1190A |

| 019. | [01] | 94914-01560 | O-RING | 22817-1150A |

| 022. | [01] | 94904-31500 | BOLT, STUD | 22857-1010 |

| 023. | [01] | 09031-70060 | PLUG, SCREW | 22845-1060A |

| 025. | [02] | 94901-20870 | WASHER, CAP | 22867-1130A |

| 026. | [01] | 94901-81500 | WASHER, COPPER PLA | 22847-1120A |

Include in #3:

09000-08310

as TIMER ASSY, AUTOMA

09180-00631

Cross reference number

| Part num | Firm num | Firm | Name |

| 09180-00631 | TIMER ASSY, AUTOMA |

Information:

CYLINDER HEAD AND VALVE MECHANISM

Inspection points1. Cylinder head Using a heavy accurate straight edge and a feeler gauge, check the bottom face for warpage in three positions lengthwise, two crosswise and two widthwise as shown in the illustration. If warpage exceeds the limit, reface the bottom face with a surface grinder.

Unit: mm (in.)

Checking cylinder head bottom face for warpage2. Rocker arms and rocker shaftMeasure the bore in the rocker arm for the rocker shaft and the diameter of the rocker shaft to find the clearance between the arm and shaft. If the clearance has reached the limit, replace the rocker arm. If it exceeds the limit, replace both arm and shaft.

Unit: mm (in.)

Measuring rocker arm and rocker shaft3. Valve springs Check the squareness and free length. If the squareness and/or free length exceeds the limit, replace the spring.

Unit: mm (in.)

Testing valve spring4. Valve push rods Using V-blocks and a dial indicator, check for bend. If the bend exceeds the limit, replace the push rod.

Unit: mm (in.)

Checking bend of valve push rod5. Valves, valve guides and valve seats(1) Diameter of valve stemMeasure the diameter of the valve stem as shown in the illustration. If the stem is worn beyond the limit, or if it is abnormally worn, replace the valve.

Unit: mm (in.)

Measuring valve stem(2) Clearance between valve stem and valve guideThe valve guide wears more rapidly at its both ends than at any other parts. Measure the bore in the guide for the stem at its ends with an inside micrometer caliper to find the clearance between the stem and guide. If the clearance exceeds the limit, replace the guide or valve whichever is badly worn.

Measuring valve guide

Unit: mm (in.) Before measuring the valve guides, clear the guides of lacquer and carbon.(3) Valve guide replacement (a) Remove the guide from the cylinder head by pushing it with a tool and an arbor press from the bottom side of the head.(b) Install a new guide into the cylinder head by pushing it with an arbor press from the upper side of the head until the specified height to the top of the guide is obtained.(c) Insert a new valve into the guide and make sure the valve slides in the guide freely.(d) After the valve guide has been replaced, check the valve contact with its seat.

Height to top of valve guide(4) Valves(a) Put a small amount of Prussian blue or read lead on the valve face. Hold the valve with a valve lapping tool (commercially available) and press it against the seat to check its contact.

Checking valve contact with seat(b) The width of contact must be uniform all the way around both seat and valve. If the contact is bad, reface the valve and seat.

Valve and valve seat contact(c) If the valve margin (valve lip thickness) exceeds the limit, replace the valve.

Unit: mm (in.)

Valve margin and sinkage(d) If the valve sinkage (the dimension from the top of a closed valve to the face of cylinder head) exceeds the limit, recondition

Inspection points1. Cylinder head Using a heavy accurate straight edge and a feeler gauge, check the bottom face for warpage in three positions lengthwise, two crosswise and two widthwise as shown in the illustration. If warpage exceeds the limit, reface the bottom face with a surface grinder.

Unit: mm (in.)

Checking cylinder head bottom face for warpage2. Rocker arms and rocker shaftMeasure the bore in the rocker arm for the rocker shaft and the diameter of the rocker shaft to find the clearance between the arm and shaft. If the clearance has reached the limit, replace the rocker arm. If it exceeds the limit, replace both arm and shaft.

Unit: mm (in.)

Measuring rocker arm and rocker shaft3. Valve springs Check the squareness and free length. If the squareness and/or free length exceeds the limit, replace the spring.

Unit: mm (in.)

Testing valve spring4. Valve push rods Using V-blocks and a dial indicator, check for bend. If the bend exceeds the limit, replace the push rod.

Unit: mm (in.)

Checking bend of valve push rod5. Valves, valve guides and valve seats(1) Diameter of valve stemMeasure the diameter of the valve stem as shown in the illustration. If the stem is worn beyond the limit, or if it is abnormally worn, replace the valve.

Unit: mm (in.)

Measuring valve stem(2) Clearance between valve stem and valve guideThe valve guide wears more rapidly at its both ends than at any other parts. Measure the bore in the guide for the stem at its ends with an inside micrometer caliper to find the clearance between the stem and guide. If the clearance exceeds the limit, replace the guide or valve whichever is badly worn.

Measuring valve guide

Unit: mm (in.) Before measuring the valve guides, clear the guides of lacquer and carbon.(3) Valve guide replacement (a) Remove the guide from the cylinder head by pushing it with a tool and an arbor press from the bottom side of the head.(b) Install a new guide into the cylinder head by pushing it with an arbor press from the upper side of the head until the specified height to the top of the guide is obtained.(c) Insert a new valve into the guide and make sure the valve slides in the guide freely.(d) After the valve guide has been replaced, check the valve contact with its seat.

Height to top of valve guide(4) Valves(a) Put a small amount of Prussian blue or read lead on the valve face. Hold the valve with a valve lapping tool (commercially available) and press it against the seat to check its contact.

Checking valve contact with seat(b) The width of contact must be uniform all the way around both seat and valve. If the contact is bad, reface the valve and seat.

Valve and valve seat contact(c) If the valve margin (valve lip thickness) exceeds the limit, replace the valve.

Unit: mm (in.)

Valve margin and sinkage(d) If the valve sinkage (the dimension from the top of a closed valve to the face of cylinder head) exceeds the limit, recondition