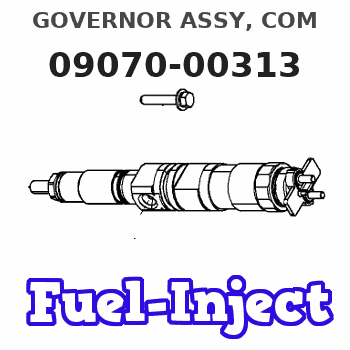

Information governor assy, com

Rating:

Scheme ###:

| 000. | [01] | 09070-00313 | GOVERNOR ASSY, COM | 22320-48071 |

| 001. | [01] | 09051-00160 | HOUSING SUB-ASSY, | 22306-77130 |

| 001-001. | [01] | 09051-30101 | BUSHING | |

| 002. | [01] | 06223-70010 | SEAL, OIL | 85613-31010 |

| 003. | [01] | 09058-00041 | DIAPHRAGM SUB-ASSY | 22303-47010 |

| 004. | [01] | 09053-00911 | LEVER SUB-ASSY, IN | 22308-48030 |

| 004-001. | [01] | 91518-05161 | BOLT, W/WASHER | |

| 006. | [01] | 94904-61430 | BOLT | 90099-04945 |

| 007. | [03] | 94900-72430 | SCREW, W/WASHER | 90099-00936 |

| 008. | [01] | 09115-90060 | ARM SUB-ASSY | 22408-77130 |

| 008. | [01] | 09115-90150 | ARM SUB-ASSY | 21408-68010 |

| 009. | [01] | 90801-10080 | O-RING | 96711-19008 |

| 010. | [01] | 09062-40021 | UNION, VENTURI PIP | 90404-48031 |

| 012. | [01] | 09055-40140 | SPRING, DIAPHRAGM | 22333-77130 |

| 013. | [01] | 09062-40010 | UNION, VENTURI PIP | 90404-12018 |

| 014. | [2C] | 09061-60080 | SHIM, MAIN SPRING | 22361-76010 |

| 014. | [2C] | 09061-60070 | SHIM, MAIN SPRING | 22362-76010 |

| 014. | [2C] | 09061-60060 | SHIM, MAIN SPRING | 22363-76010 |

| 014. | [2C] | 09061-60050 | SHIM, MAIN SPRING | 22364-76010 |

| 015. | [01] | 09061-50470 | SPRING, GOVERNOR M | 22326-48030 |

| 016. | [02] | 09024-80010 | WASHER, DRAIN SCRE | 22378-76010 |

| 017. | [02] | 09078-20010 | SCREW | 22386-46010 |

| 018. | [01] | 09057-30070 | BOLT, DIAPHRAGM CO | 22329-77130 |

| 019. | [01] | 09057-30050 | BOLT, DIAPHRAGM CO | 22329-77021 |

| 020. | [01] | 90400-02101 | PIN, SPLIT | 90095-02001 |

| 021. | [01] | 90200-06001 | WASHER, PLATE | 90093-00602 |

| 022. | [02] | 90258-05001 | WASHER, SPRING | 90032-04023 |

| 023. | [02] | 91170-05321 | NUT, HEXAGON | 90092-20582 |

| 025. | [06] | 94912-00260 | BALL, STEEL | 90099-12010 |

| 026. | [01] | 09063-00170 | CAPSULE, IDLING | 22318-48030 |

| 027. | [01] | 09064-50010 | NUT, GOVERNOR IDRI | 22319-77010 |

| 028. | [01] | 09065-50020 | GUIDE, BALL | 22693-77130 |

| 029. | [01] | 09073-00010 | SLIDER SUB-ASSY | 22692-77130 |

| 029. | [01] | 09073-00040 | SLIDER SUB-ASSY | 22692-77131 |

| 030. | [01] | 94901-35120 | WASHER, PLATE, SK | 90099-01441 |

| 031. | [01] | 09066-40040 | SHEET, SPRING | 22696-56040 |

| 031. | [01] | 94901-35110 | WASHER, PLATE, SK | 90099-01440 |

| 032. | [01] | 09099-20521 | SPRING, SPEED CONT | 22449-48030 |

| 033. | [01] | 09065-60010 | BEARING SUB-ASSY | 22694-77130 |

| 034. | [01] | 09062-10070 | HOUSING, GOVERNOR | 22323-77010 |

| 034. | [01] | 09062-10160 | HOUSING, GOVERNOR | |

| 035. | [01] | 09064-70030 | PLUG, DIAPHRAGM HO | 22311-77130 |

| 035. | [01] | 09109-40140 | CAP, LEVER | 22457-58010 |

| 036. | [02] | 94901-81020 | WASHER, COPPER PLA | 90201-08106 |

| 037. | [01] | 94905-03390 | NUT, HEXAGON | 22825-1100A |

| 037. | [01] | 94805-30130 | NUT, HEXAGON, W/HO | 90099-05133 |

| 038. | [01] | 09103-10020 | NUT, CAP | 22437-77130 |

| 039. | [01] | 09101-11140 | COVER, GOVERNOR | 22703-77130 |

| 039. | [01] | 09101-11540 | COVER, GOVERNOR | 22703-68010 |

| 040. | [01] | 09082-30350 | GASKET | 22442-77130 |

| 040. | [01] | 09082-30200 | GASKET | |

| 041. | [06] | 91418-06251 | BOLT, W/WASHER | 90091-20605 |

| 042. | [01] | 94901-34190 | WASHER, PLATE, SK | |

| 043. | [01] | 09082-30460 | GASKET | 22442-58260 |

| 043. | [01] | 09082-30360 | GASKET | 22442-77131 |

| 043. | [01] | 09082-30220 | GASKET | |

| 043. | [01] | 09082-30210 | GASKET | |

| 045. | [01] | 09066-20010 | PIN, SHIFTING | 22698-77130 |

| 045. | [01] | 09066-20020 | PIN, SHIFTING | 22698-77131 |

| 046. | [01] | 94901-50500 | WASHER, SPRING | 22348-76010 |

| 047. | [01] | 19066-00010 | ARM KIT, COMBINED | 22697-77130 |

| 047. | [01] | 19066-00030 | ARM KIT, COMBINED | 22697-77131 |

| 047-001. | [01] | 09066-00011 | ARM SUB-ASSY | 22697-77130 |

| 047-001. | [01] | 09066-00020 | ARM SUB-ASSY | |

| 047-002. | [01] | 09053-00700 | LEVER SUB-ASSY, IN | 22308-77130 |

| 047-003. | [01] | 09055-30020 | BOLT, GOVERNOR STO | 22332-77021 |

| 048. | [01] | 09084-40010 | NUT, ROUND | 22451-77123 |

| 049. | [01] | 09009-20070 | BRACKET | 22178-48024 |

| 050. | [01] | 94905-30040 | NUT, HEXAGON, W/ H | 90099-05056 |

| 051. | [01] | 09056-00032 | CAPSULE, FULL STOP | 22336-46010 |

| 051. | [01] | 09056-00110 | CAPSULE, FULL STOP | 22336-68010 |

| 052. | [01] | 94913-00010 | KEY, WOODRUFF | 90099-13001 |

| 053. | [01] | 94901-34330 | WASHER, PLATE, SK | 90099-01445 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09070-00313 | 22320-4807 | GOVERNOR ASSY, COM |

Information:

Fill the fuel tank at the end of each day of operation to drive out moist air and prevent condensation. Maintain a fairly consistent level in the day tank (near the top) to avoid drawing moisture into the tank as the level decreases.Do not fill the tank to the top. Fuel expands as it warms, and may overflow.Do not fill fuel filters with fuel before installing them. Contaminated fuel causes accelerated wear to fuel system parts.

Use fuel only as recommended in this section. Fuel grades recommended for use in Caterpillar diesel engines are: No.2-D diesel fuel with low sulfur (0.05 percent maximum), or regular sulfur (0.5 percent maximum). No. 1 grades are acceptable.The following chart lists worldwide fuel standards which meet Caterpillar requirements. Aviation kerosene-type fuels meeting acceptable limits may also be used as an engine fuel. The following chart lists some of the acceptable kerosene-type fuels. Fuel viscosity is a major concern with aviation fuels. A minimum viscosity of 1.4 cSt at 38°C (100°F) is required to properly lubricate Caterpillar fuel system components. These kerosene-type fuels have a lower viscosity for low temperature operation.The kerosene-type fuels have less energy per unit volume than diesel fuels, producing less peak power. More kerosene-type fuel is needed than diesel fuel to do the same amount of work.Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. Burning clean, stable blends of distillate fuel meeting the following requirements will provide quality engine service life. When economics or fuel availability dictate, other fuel types may be burned in the engine. Consult your Caterpillar dealer for more information and advice on any specific fuel.Cetane Number

Under average starting conditions, direct injection engines require a minimum cetane number of 40. A higher cetane value may be required for high altitude or cold weather operation.Filterability

Clean fuels should have no more than 0.1 percent of sediment and water. Fuel stored for extended periods of time may oxidize and form solids, causing filtering problems.Pour Point

Fuel pour point should be at least 6°C (10°F) below the lowest ambient temperature at which the engines must start and operate. Lower pour points of No.1 or No.1-D fuel may be necessary in extremely cold weather.Cloud Point

The cloud point should be below the lowest ambient temperature at which the engines must start and operate, to prevent the fuel filter elements from plugging with wax crystals. Refer to Fuel Problems in Cold Weather Operation for additional information.Viscosity

Fluid viscosity is a measure of resistance to flow. Fuel viscosity is important because it effects lubrication of fuel system components, and fuel atomization. The provided viscosity limits address both of those effects.Additives

Fuel additives are generally not recommended or needed for the specified fuels listed. Acetone improvers can be used as necessary for direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the