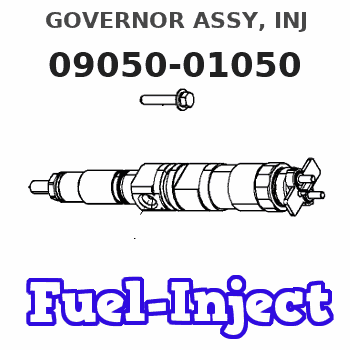

Information governor assy, inj

Rating:

KIT List:

| Governor assy, inj | 1908900260 |

| Governor assy, inj | 1908900260 |

Scheme ###:

| 000. | [01] | 09050-01050 | GOVERNOR ASSY, INJ | |

| 001. | [01] | 09051-00110 | HOUSING SUB-ASSY, | |

| 002. | [01] | 09063-00030 | CAPSULE, IDLING | |

| 003. | [01] | 09064-50010 | NUT, GOVERNOR IDRI | |

| 004. | [01] | 09109-40140 | CAP, LEVER | |

| 005. | [01] | 09061-50270 | SPRING, GOVERNOR M | |

| 006. | [ C] | 09061-60080 | SHIM, MAIN SPRING | |

| 006. | [ C] | 09061-60070 | SHIM, MAIN SPRING | |

| 006. | [ C] | 09061-60060 | SHIM, MAIN SPRING | |

| 006. | [ C] | 09061-60050 | SHIM, MAIN SPRING | |

| 007. | [01] | 09052-50010 | COVER, CAMSHAFT | 22335-70020 |

| 008. | [03] | 91510-05081 | BOLT, W/WASHER | |

| 009. | [01] | 90258-05001 | WASHER, SPRING | 94511-00500 |

| 010. | [01] | 94915-01750 | SEAL, OIL | |

| 011. | [02] | 90258-08001 | WASHER, SPRING | 94511-00800 |

| 012. | [01] | 09057-30050 | BOLT, DIAPHRAGM CO | |

| 013. | [02] | 94914-00600 | O-RING | |

| 014. | [01] | 91170-05321 | NUT, HEXAGON | 90092-20582 |

| 015. | [01] | 90200-06001 | WASHER, PLATE | |

| 016. | [01] | 90400-02101 | PIN, SPLIT | 22144-73600-71 |

| 017. | [01] | 09053-10191 | LEVER, PNEUMATIC G | |

| 018. | [02] | 90190-08651 | NUT, HEXAGON | 94110-40800 |

| 019. | [03] | 94900-72430 | SCREW, W/WASHER | |

| 020. | [01] | 94904-61430 | BOLT | |

| 022. | [01] | 19055-00040 | LEVER KIT, GOVERNO | 22334-48010 |

| 024. | [01] | 09062-10160 | HOUSING, GOVERNOR | |

| 026. | [01] | 09053-01300 | LEVER SUB-ASSY, IN | |

| 027. | [01] | 09055-40011 | SPRING, DIAPHRAGM | |

| 028. | [01] | 09056-00032 | CAPSULE, FULL STOP | 22336-46010 |

| 029. | [01] | 94905-30040 | NUT, HEXAGON, W/ H | |

| 030. | [01] | 09058-00041 | DIAPHRAGM SUB-ASSY | 22303-95355-71 |

| 032. | [01] | 09078-20010 | SCREW | |

| 033. | [02] | 09062-40010 | UNION, VENTURI PIP | |

| 035. | [02] | 09024-80010 | WASHER, DRAIN SCRE | 22121-30890-71 |

| 036. | [01] | 90000-06081 | SCREW, SLOTTED PAN | |

| 037. | [02] | 94901-33730 | WASHER, PLATE, SK |

Include in #3:

09050-01050

as GOVERNOR ASSY, INJ

Cross reference number

| Part num | Firm num | Firm | Name |

| 09050-01050 | GOVERNOR ASSY, INJ |

Information:

Water Temperature Regulators (Thermostats)

Replace

Replacing your thermostats prior to failure is a recommended preventive maintenance practice because it reduces the chances for unscheduled downtime.Depending on load, a thermostat that fails in a partially opened position will cause either an overheating or an over cooling condition.If the thermostat fails in the closed position, it will cause excessive overheating. Excessive overheating could result in cylinder head cracking or piston seizure problems.If the thermostat fails in the open position, it will cause the engine operating temperature to be too low during partial load operation. Low engine operating temperatures during partial loads could cause an excessive carbon build-up inside the cylinder. This excessive carbon build-up could result in accelerated ring and liner wear.

Failure to replace your thermostat on a regularly scheduled basis could cause severe engine damage.Caterpillar engines incorporate a shunt design cooling system and require operating the engine with a thermostat installed.If the thermostat is installed wrong, the engine may overheat, causing cylinder head damage. Ensure that the new thermostat is installed in the original position. Ensure that the thermostat vent hole is open.DO NOT use liquid gasket material on the gasket or cylinder head surface.

Refer to the Service Manual for the water temperature regulator replacement procedure, or consult with your Caterpillar dealer. If replacing thermostats ONLY, drain the coolant from the cooling system to a level below the thermostat housing.Refer to the Cooling System Specifications in this publication for all information regarding Acceptable Water, coolant/antifreeze and SCA requirements, or contact your Caterpillar dealer for assistance.Cooling System (Extended Life Coolant Only)

Add Extender

Caterpillar Extended Life Coolant (ELC) does not require the frequent Supplemental Coolant Additive (SCA) additions associated with the present conventional coolants. Only a "one time" coolant Extender is required.Extender should be added to ELC after 3000 service hours or two years, whichever comes first.Check the cooling system only when the engine is stopped and cool.1. Loosen the cooling system filler cap slowly to relieve pressure. Remove the cap.2. It may be necessary to drain enough coolant from the cooling system to allow for the addition of the Extender.3. Add Extender according to the requirements for your engine's cooling system capacity. Refer to the Refill Capacities chart in this manual for the cooling system capacity for your engine. Refer to the Coolant Specifications in this manual for the Caterpillar ELC Extender Additions chart.4. Clean the filler cap. Inspect the filler cap gaskets. Replace the cap if the gaskets are damaged. Clean the filler cap receptacle. Install the cap.Cooling System (Conventional HD Coolant Only)

Drain/Clean/Replace Coolant

Clean/Flush the cooling system before the recommended maintenance interval if:* the coolant is heavily contaminated* the engine overheats frequently* foaming is observed* the oil cooler has failed, allowing oil to contaminate the coolant* fuel has entered the cooling system and contaminated the coolant

Use of commercially available cooling system cleaners may cause damage to cooling system components. Use only cooling system cleaners that are approved for Caterpillar engines.

A good time to inspect the water pump, replace the thermostat, and replace

Replace

Replacing your thermostats prior to failure is a recommended preventive maintenance practice because it reduces the chances for unscheduled downtime.Depending on load, a thermostat that fails in a partially opened position will cause either an overheating or an over cooling condition.If the thermostat fails in the closed position, it will cause excessive overheating. Excessive overheating could result in cylinder head cracking or piston seizure problems.If the thermostat fails in the open position, it will cause the engine operating temperature to be too low during partial load operation. Low engine operating temperatures during partial loads could cause an excessive carbon build-up inside the cylinder. This excessive carbon build-up could result in accelerated ring and liner wear.

Failure to replace your thermostat on a regularly scheduled basis could cause severe engine damage.Caterpillar engines incorporate a shunt design cooling system and require operating the engine with a thermostat installed.If the thermostat is installed wrong, the engine may overheat, causing cylinder head damage. Ensure that the new thermostat is installed in the original position. Ensure that the thermostat vent hole is open.DO NOT use liquid gasket material on the gasket or cylinder head surface.

Refer to the Service Manual for the water temperature regulator replacement procedure, or consult with your Caterpillar dealer. If replacing thermostats ONLY, drain the coolant from the cooling system to a level below the thermostat housing.Refer to the Cooling System Specifications in this publication for all information regarding Acceptable Water, coolant/antifreeze and SCA requirements, or contact your Caterpillar dealer for assistance.Cooling System (Extended Life Coolant Only)

Add Extender

Caterpillar Extended Life Coolant (ELC) does not require the frequent Supplemental Coolant Additive (SCA) additions associated with the present conventional coolants. Only a "one time" coolant Extender is required.Extender should be added to ELC after 3000 service hours or two years, whichever comes first.Check the cooling system only when the engine is stopped and cool.1. Loosen the cooling system filler cap slowly to relieve pressure. Remove the cap.2. It may be necessary to drain enough coolant from the cooling system to allow for the addition of the Extender.3. Add Extender according to the requirements for your engine's cooling system capacity. Refer to the Refill Capacities chart in this manual for the cooling system capacity for your engine. Refer to the Coolant Specifications in this manual for the Caterpillar ELC Extender Additions chart.4. Clean the filler cap. Inspect the filler cap gaskets. Replace the cap if the gaskets are damaged. Clean the filler cap receptacle. Install the cap.Cooling System (Conventional HD Coolant Only)

Drain/Clean/Replace Coolant

Clean/Flush the cooling system before the recommended maintenance interval if:* the coolant is heavily contaminated* the engine overheats frequently* foaming is observed* the oil cooler has failed, allowing oil to contaminate the coolant* fuel has entered the cooling system and contaminated the coolant

Use of commercially available cooling system cleaners may cause damage to cooling system components. Use only cooling system cleaners that are approved for Caterpillar engines.

A good time to inspect the water pump, replace the thermostat, and replace