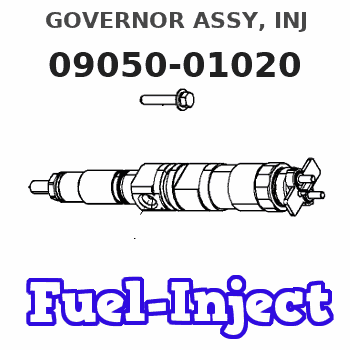

Information governor assy, inj

Rating:

KIT List:

| Governor assy, inj | 1908900260 |

| Governor assy, inj | 1908900260 |

| Governor assy, inj | 1908900260 |

| Governor assy, inj | 1908900260 |

Scheme ###:

| 000. | [01] | 09050-01020 | GOVERNOR ASSY, INJ | ME703893 |

| 001. | [01] | 09051-00100 | HOUSING SUB-ASSY, | ME023394 |

| 002. | [01] | 94919-22580 | COLLAR, STEEL | ME703894 |

| 003. | [01] | 90258-08001 | WASHER, SPRING | ME702038 |

| 004. | [01] | 09062-10070 | HOUSING, GOVERNOR | ME703895 |

| 005. | [01] | 09061-50360 | SPRING, GOVERNOR M | ME703594 |

| 006. | [ C] | 09061-60050 | SHIM, MAIN SPRING | ME703595 |

| 006. | [ C] | 09061-60060 | SHIM, MAIN SPRING | ME703596 |

| 006. | [ C] | 09061-60070 | SHIM, MAIN SPRING | ME703597 |

| 006. | [ C] | 09061-60080 | SHIM, MAIN SPRING | ME703598 |

| 007. | [01] | 09063-00080 | CAPSULE, IDLING | ME703896 |

| 008. | [01] | 09064-50010 | NUT, GOVERNOR IDRI | ME703897 |

| 009. | [01] | 09064-70030 | PLUG, DIAPHRAGM HO | ME703898 |

| 010. | [01] | 09057-30050 | BOLT, DIAPHRAGM CO | ME023343 |

| 015. | [01] | 09062-40030 | UNION, VENTURI PIP | ME023340 |

| 016. | [01] | 09082-30460 | GASKET | |

| 016. | [01] | 09082-30360 | GASKET | |

| 016. | [01] | 09082-30210 | GASKET | ME703075 |

| 017. | [01] | 90190-08051 | NUT, HEXAGON | ME703899 |

| 018. | [02] | 94904-61430 | BOLT | ME703074 |

| 019. | [02] | 94900-72430 | SCREW, W/WASHER | ME703073 |

| 020. | [01] | 09024-20080 | NIPPLE, AIR BLEEDE | ME703900 |

| 021. | [01] | 94915-00050 | SEAL, OIL | |

| 021. | [01] | 94915-01750 | SEAL, OIL | ME703901 |

| 022. | [01] | 09052-50010 | COVER, CAMSHAFT | ME023392 |

| 023. | [01] | 94918-10150 | NIPPLE, SWIVELING | ME023411 |

| 024. | [03] | 09024-10010 | WASHER, AIR BLEEDE | ME702102 |

| 025. | [01] | 09054-10160 | SHAFT, GOVERNOR ST | ME703902 |

| 026. | [01] | 09265-10950 | LEVER, THROTTLE | ME703903 |

| 027. | [01] | 94914-00600 | O-RING | ME023412 |

| 028. | [02] | 94907-10070 | WASHER, SNAP | ME023388 |

| 029. | [ C] | 94901-14860 | WASHER, STEEL PLAT | ME023390 |

| 029. | [ C] | 94901-14850 | WASHER, STEEL PLAT | ME023389 |

| 030. | [01] | 09055-10030 | LEVER, GOVERNOR ST | ME023342 |

| 031. | [01] | 09055-30020 | BOLT, GOVERNOR STO | ME022432 |

| 032. | [01] | 09055-40011 | SPRING, DIAPHRAGM | ME023382 |

| 033. | [01] | 09056-90010 | SCREW, FULL STOP | ME703078 |

| 034. | [01] | 94905-30040 | NUT, HEXAGON, W/ H | ME023383 |

| 035. | [01] | 09078-20010 | SCREW | ME023341 |

| 036. | [01] | 09058-00041 | DIAPHRAGM SUB-ASSY | ME023344 |

| 037. | [01] | 94918-00050 | SCREW, HOLLOW | ME702926 |

| 040. | [02] | 09024-80010 | WASHER, DRAIN SCRE | ME702175 |

| 041. | [02] | 94901-33730 | WASHER, PLATE, SK | ME022239 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09050-01020 | ME703893 | GOVERNOR ASSY, INJ | |

| ME703893 | MITSUBISHI | GOVERNOR ASSY, INJ |

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner - Check service indicator/Service air cleaner when needed Air Starter (If Equipped) - Check lubricator oil level Clutch (If Equipped) - Check/Adjust/Lubricate Marine Transmission - Check oil levelEvery 3800 L (1000 gal) of Fuel or 50 Hours

Zinc Rods - Inspect/ReplaceEvery 19,000 L (5,000 gal) Of Fuel Or 250 Hours or Yearly

Fuel System - Clean primary fuel filter (if equipped)/Replace final fuel filter Fuel Tank - Drain water and sediment Cooling System (Conventional HD Coolant Only) - Test for SCA concentration OR obtain Level I coolant analysis/Add SCA if necessary Air Cleaner - Clean/Replace air filter elements Belts - Check/Adjust/Replace Hoses and Clamps - Inspect/Replace Batteries - Clean/Check (if required)First 38,000 L (10,000 gal) of Fuel or 500 Hours

Valve Lash - Check/Adjust (at the first oil change interval)Every 38,000 L (10,000 gal) of Fuel or 500 Hours

Scheduled Oil Sampling (S O S) - Obtain Sample and analysis Engine Crankcase - Replace oil and filter(s) Crankcase Breathers - CleanEvery 76,000 L (20,000 gal) Of Fuel Or 1000 Hours

Engine Protection Devices - Inspect/Check Magnetic Pickup - Inspect/AdjustEvery 227,500 L (60,000 gal) Of Fuel Or 3000 Hours

Water Temperature Regulators (Thermostats) - Replace Cooling System (Extended Life Coolant Only) - Add Extender1 Cooling System (Conventional HD Coolant Only) - Drain/Clean/Replace coolant Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect Valve Lash, Valve Rotators - Check/Adjust Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust PAR Analysis - ObtainEvery 379,000 L (100,000 gal) Of Fuel Or 5000 Hours

Fuel Injection Nozzles - Test/Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Raw/Sea Water Pump - Inspect/Rebuild or Exchange Alternator - Inspect/Rebuild or Exchange Starting Motor - Inspect/Rebuild or Exchange Air Compressor (If Equipped) - Inspect/Rebuild or Exchange Turbocharger - Clean/Inspect/CheckEvery 6000 Hours Or Four Years

Cooling System (Extended Life Coolant Only) - Drain/Flush/Replace CoolantOverhaul

Overhaul Considerations1If a commercial HD coolant/antifreeze meeting ASTM D4985 specifications is used, or if a mixture of commercial SCA and water is used, this maintenance should be performed at a maximum of One Year.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner - Check service indicator/Service air cleaner when needed Air Starter (If Equipped) - Check lubricator oil level Clutch (If Equipped) - Check/Adjust/Lubricate Marine Transmission - Check oil levelEvery 3800 L (1000 gal) of Fuel or 50 Hours

Zinc Rods - Inspect/ReplaceEvery 19,000 L (5,000 gal) Of Fuel Or 250 Hours or Yearly

Fuel System - Clean primary fuel filter (if equipped)/Replace final fuel filter Fuel Tank - Drain water and sediment Cooling System (Conventional HD Coolant Only) - Test for SCA concentration OR obtain Level I coolant analysis/Add SCA if necessary Air Cleaner - Clean/Replace air filter elements Belts - Check/Adjust/Replace Hoses and Clamps - Inspect/Replace Batteries - Clean/Check (if required)First 38,000 L (10,000 gal) of Fuel or 500 Hours

Valve Lash - Check/Adjust (at the first oil change interval)Every 38,000 L (10,000 gal) of Fuel or 500 Hours

Scheduled Oil Sampling (S O S) - Obtain Sample and analysis Engine Crankcase - Replace oil and filter(s) Crankcase Breathers - CleanEvery 76,000 L (20,000 gal) Of Fuel Or 1000 Hours

Engine Protection Devices - Inspect/Check Magnetic Pickup - Inspect/AdjustEvery 227,500 L (60,000 gal) Of Fuel Or 3000 Hours

Water Temperature Regulators (Thermostats) - Replace Cooling System (Extended Life Coolant Only) - Add Extender1 Cooling System (Conventional HD Coolant Only) - Drain/Clean/Replace coolant Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect Valve Lash, Valve Rotators - Check/Adjust Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust PAR Analysis - ObtainEvery 379,000 L (100,000 gal) Of Fuel Or 5000 Hours

Fuel Injection Nozzles - Test/Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Raw/Sea Water Pump - Inspect/Rebuild or Exchange Alternator - Inspect/Rebuild or Exchange Starting Motor - Inspect/Rebuild or Exchange Air Compressor (If Equipped) - Inspect/Rebuild or Exchange Turbocharger - Clean/Inspect/CheckEvery 6000 Hours Or Four Years

Cooling System (Extended Life Coolant Only) - Drain/Flush/Replace CoolantOverhaul

Overhaul Considerations1If a commercial HD coolant/antifreeze meeting ASTM D4985 specifications is used, or if a mixture of commercial SCA and water is used, this maintenance should be performed at a maximum of One Year.