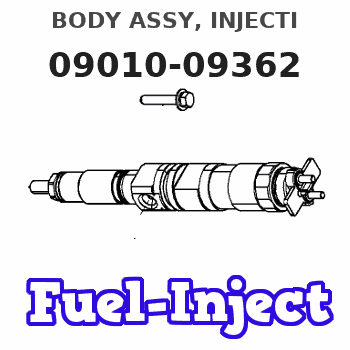

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-09362 | BODY ASSY, INJECTI | |

| 001. | [01] | 09011-04350 | HOUSING SUB-ASSY, | |

| 001. | [01] | 09011-05720 | HOUSING SUB-ASSY, | |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 94904-30010 |

| 002. | [06] | 09013-00510 | HOLDER SUB-ASSY, D | |

| 002. | [06] | 09013-00540 | HOLDER SUB-ASSY, D | |

| 003. | [06] | 09013-61010 | SPRING, DELIVERY V | 09013-61010 |

| 004. | [06] | 94914-02570 | O-RING | |

| 005. | [06] | 09014-02020 | VALVE SUB-ASSY, IN | 09014-02020 |

| 006. | [06] | 09015-04661 | ELEMENT SUB-ASSY, | 09015-04661 |

| 006. | [06] | 09015-05162 | ELEMENT SUB-ASSY, | |

| 006. | [06] | 09015-06160 | ELEMENT SUB-ASSY, | |

| 007. | [06] | 09016-00150 | SLEEVE SUB-ASSY, C | 09016-00150 |

| 008. | [01] | 09021-20471 | RACK, CONTROL | 09021-20471 |

| 009. | [06] | 09016-30160 | SEAT, SPRING, UPR | 09016-30160 |

| 010. | [06] | 09016-40250 | SPRING, PUMP PLUNG | |

| 011. | [06] | 09016-50150 | SEAT, SPRING, LWR | |

| 012. | [06] | 09017-00320 | TAPPET SUB-ASSY,IN | |

| 013. | [ C] | 09043-80471 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80481 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80881 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80891 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80901 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80911 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80461 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80451 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80391 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80401 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80411 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80421 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80431 | SHIM, ELEMENT HOLD | |

| 013. | [ C] | 09043-80441 | SHIM, ELEMENT HOLD | |

| 014. | [12] | 90196-08651 | NUT, HEXAGON | |

| 015. | [12] | 94901-35880 | WASHER, PLATE, SK | |

| 016. | [12] | 90258-08001 | WASHER, SPRING | 90258-08001 |

| 017. | [01] | 09020-60240 | GASKET, BEARING CO | |

| 017. | [01] | 09020-60070 | GASKET, BEARING CO | 09020-60070 |

| 018. | [18] | 09013-90020 | O-RING | |

| 018. | [12] | 09013-90340 | O-RING | |

| 019. | [06] | 94901-81730 | WASHER, COPPER PLA | |

| 020. | [01] | 09019-11500 | CAMSHAFT, INJECTIO | |

| 021. | [01] | 94910-10140 | BEARING, ROLLER | |

| 022. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | 09019-30050 |

| 023. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH | |

| 023. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | 09019-40360 |

| 023. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | 09019-40350 |

| 023. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | 09019-40340 |

| 023. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | 09019-40100 |

| 023. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | 09019-40090 |

| 023. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | 09019-40080 |

| 023. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | 09019-40070 |

| 025. | [01] | 94915-01420 | SEAL, OIL | |

| 025. | [01] | 94915-02820 | SEAL, OIL | |

| 026. | [01] | 09020-10501 | COVER, BEARING | |

| 027. | [04] | 91418-06201 | BOLT, W/WASHER | 91418-06201 |

| 028. | [01] | 09043-30020 | RETAINER, BEARING | |

| 029. | [01] | 09036-10180 | BEARING, CENTER | |

| 029. | [01] | 09036-10240 | BEARING, CENTER | |

| 030. | [02] | 94900-67300 | SCREW | |

| 030. | [02] | 94900-66510 | SCREW | |

| 030. | [02] | 90015-06181 | SCREW, SLOTTED OVA | |

| 031. | [04] | 09024-80010 | WASHER, DRAIN SCRE | 09024-80010 |

| 032. | [01] | 09021-50060 | SCREW, RACK GUIDE | |

| 033. | [01] | 09031-70140 | PLUG, SCREW | |

| 034. | [01] | 94910-10130 | BEARING, ROLLER | |

| 035. | [01] | 09019-30060 | RING, CAMSHAFT ADJ | |

| 036. | [04] | 09022-20070 | WASHER, FUEL PIPE | 09022-20070 |

| 038. | [01] | 94918-00310 | SCREW, HOLLOW | 94918-00310 |

| 039. | [3C] | 09019-40420 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40390 | PLATE, CAMSHAFT SH | 09019-40390 |

| 039. | [3C] | 09019-40380 | PLATE, CAMSHAFT SH | 09019-40380 |

| 039. | [3C] | 09019-40370 | PLATE, CAMSHAFT SH | 09019-40370 |

| 039. | [3C] | 09019-40330 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40320 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40310 | PLATE, CAMSHAFT SH | |

| 039. | [3C] | 09019-40300 | PLATE, CAMSHAFT SH | |

| 040. | [02] | 09011-40110 | BUSHING, CONTROL R | |

| 041. | [01] | 09036-70040 | BUSHING, CONTROL R | |

| 046. | [01] | 94914-00380 | O-RING | 94914-00380 |

| 047. | [03] | 90258-06001 | WASHER, SPRING | 90258-06001 |

| 048. | [03] | 90160-06051 | NUT, HEXAGON | 90160-06051 |

| 049. | [02] | 09024-40160 | SCREW, AIR BLEEDER | |

| 053. | [01] | 09031-00191 | VALVE ASSY, OVERFL | |

| 053. | [01] | 09031-00370 | VALVE ASSY, OVERFL | |

| 059. | [01] | 94901-80350 | WASHER, COPPER PLA | 94901-80350 |

| 060. | [6C] | 94901-35140 | WASHER, PLATE, SK | |

| 060. | [6C] | 94901-35940 | WASHER, PLATE, SK | |

| 060. | [6C] | 94901-35930 | WASHER, PLATE, SK | |

| 060. | [6C] | 90208-04610 | WASHER, PLATE |

Include in #3:

09010-09362

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-09362 | BODY ASSY, INJECTI |

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Engine Air Cleaner - Check indicator, clean and replace elements, if necessary Air-to-Air Aftercooler System - Check, clean if necessaryPM Level 1

Every 2,000 gal (7580 L) of Fuel or 12,500 Miles (20 000 km) or 250 Hours* Scheduled Oil Sampling (S O S) Analysis -Obtain Engine Oil and Filter(s)2 - Replace 3 Fuel Filters - Replace final filter and Clean/Replace primary filter (if equipped) 3 Cooling System - Test for concentration/Add coolant additive or Replace supplemental additive element (if equipped) Crankcase Breather - Clean Alternator, Fan and Accessory Drive Belts -Inspect/Replace Hoses and Clamps - Inspect/Replace Air-to-Air Aftercooler System - Inspect/Check Cylinder Head Grounding Stud -Inspect/Clean/Tighten Engine Valve Lash (at Initial PM 1 Interval) -Check/Adjust Radiator Fins - Inspect/CheckPM Level 2

Every 26,600 gal (100 000 L) of Fuel or 166,000 Miles (267 250 km) or 3,330 Hours* Performance Analysis Report (PAR) - Obtain Engine - Steam clean Thermostat - Replace Cooling System - Clean/Flush Water Pump - Rebuild or Exchange Electronic Unit Injectors - Test Engine Valve Lash and Electronic Unit Injector Preload - Check/Adjust Jacobs Brake Slave Lash - Check/AdjustPM Level 3

Every 40,000 gal (151 600 L) of Fuel or 250,000 Miles (402 500 km) or 5,000 Hours* Air Compressor - Rebuild or Exchange Turbocharger - Rebuild or Exchange Engine Mounts - Inspect/Check Throttle Position Sensor - Check/Adjust calibrationOverhaul

Every 80,000 gal (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Hours* Overhaul Information Cylinder Head Assembly - Rebuild or Exchange Cylinder Packs - Exchange Spacer Block - Inspect Camshaft Followers - Inspect Oil Pump and Fuel Transfer Pump - Inspect Thrust, Main and Rod Bearings - Replace Valve Rotators - Replace Thermostat - Replace Throttle Position Sensor - Replace Crankshaft - Inspect Camshaft - Inspect Vibration Damper - Inspect Electronic Unit Injectors - Test Oil Cooler and Air-to-Air Aftercooler Core -Clean/Test*First Perform Previous Service Hour Items2Remote mounted or auxiliary filters require additional oil. When changing oil, overfill crankcase by amount needed for auxiliary system (if equipped).3To prevent crankshaft and/or bearing damage, crank engine to fill all filters before starting engine.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Engine Air Cleaner - Check indicator, clean and replace elements, if necessary Air-to-Air Aftercooler System - Check, clean if necessaryPM Level 1

Every 2,000 gal (7580 L) of Fuel or 12,500 Miles (20 000 km) or 250 Hours* Scheduled Oil Sampling (S O S) Analysis -Obtain Engine Oil and Filter(s)2 - Replace 3 Fuel Filters - Replace final filter and Clean/Replace primary filter (if equipped) 3 Cooling System - Test for concentration/Add coolant additive or Replace supplemental additive element (if equipped) Crankcase Breather - Clean Alternator, Fan and Accessory Drive Belts -Inspect/Replace Hoses and Clamps - Inspect/Replace Air-to-Air Aftercooler System - Inspect/Check Cylinder Head Grounding Stud -Inspect/Clean/Tighten Engine Valve Lash (at Initial PM 1 Interval) -Check/Adjust Radiator Fins - Inspect/CheckPM Level 2

Every 26,600 gal (100 000 L) of Fuel or 166,000 Miles (267 250 km) or 3,330 Hours* Performance Analysis Report (PAR) - Obtain Engine - Steam clean Thermostat - Replace Cooling System - Clean/Flush Water Pump - Rebuild or Exchange Electronic Unit Injectors - Test Engine Valve Lash and Electronic Unit Injector Preload - Check/Adjust Jacobs Brake Slave Lash - Check/AdjustPM Level 3

Every 40,000 gal (151 600 L) of Fuel or 250,000 Miles (402 500 km) or 5,000 Hours* Air Compressor - Rebuild or Exchange Turbocharger - Rebuild or Exchange Engine Mounts - Inspect/Check Throttle Position Sensor - Check/Adjust calibrationOverhaul

Every 80,000 gal (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Hours* Overhaul Information Cylinder Head Assembly - Rebuild or Exchange Cylinder Packs - Exchange Spacer Block - Inspect Camshaft Followers - Inspect Oil Pump and Fuel Transfer Pump - Inspect Thrust, Main and Rod Bearings - Replace Valve Rotators - Replace Thermostat - Replace Throttle Position Sensor - Replace Crankshaft - Inspect Camshaft - Inspect Vibration Damper - Inspect Electronic Unit Injectors - Test Oil Cooler and Air-to-Air Aftercooler Core -Clean/Test*First Perform Previous Service Hour Items2Remote mounted or auxiliary filters require additional oil. When changing oil, overfill crankcase by amount needed for auxiliary system (if equipped).3To prevent crankshaft and/or bearing damage, crank engine to fill all filters before starting engine.