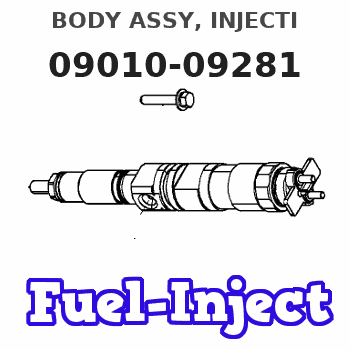

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-09281 | BODY ASSY, INJECTI | 22110-2690 |

| 001. | [01] | 19011-04490 | HOUSING KIT, INJEC | 22101-2710A |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 22857-1060A |

| 001-002. | [01] | 09022-10070 | UNION, INJECTION P | 22131-1050A |

| 001-003. | [01] | 09022-10330 | UNION, INJECTION P | |

| 001-003. | [01] | 09022-10022 | UNION, INJECTION P | 22131-1040 |

| 003. | [04] | 09013-10320 | HOLDER, DELIVERY V | 22116-1100A |

| 004. | [04] | 09013-30010 | STOPPER, DELIVERY | 22117-1040A |

| 005. | [04] | 09013-60120 | SPRING, DELIVERY V | 22125-1070A |

| 006. | [04] | 09013-70100 | GASKET, DELIVERY V | 22847-1720A |

| 007. | [04] | 09014-01280 | VALVE SUB-ASSY, IN | 22103-1460A |

| 008. | [04] | 09015-04790 | ELEMENT SUB-ASSY, | 22104-2690A |

| 009. | [04] | 09015-60010 | PINION, PLUNGER CO | 22128-1020A |

| 010. | [04] | 09015-70010 | SCREW, PLUNGER CON | 22865-1280A |

| 011. | [04] | 09016-10330 | SLEEVE, PLUNGER CO | 22118-1310A |

| 012. | [04] | 09016-30120 | SEAT, SPRING, UPR | 22119-1010A |

| 012. | [04] | 09016-30191 | SEAT, SPRING, UPR | 22119-1190A |

| 013. | [04] | 09016-40350 | SPRING, PUMP PLUNG | 22121-1430A |

| 013. | [04] | 09016-40320 | SPRING, PUMP PLUNG | 22121-1270A |

| 014. | [04] | 09016-50160 | SEAT, SPRING, LWR | 22122-1120A |

| 015. | [04] | 09017-00070 | TAPPET SUB-ASSY,IN | 22105-1020A |

| 016. | [04] | 09018-90090 | PLUG, INJECTION PU | 22845-1420A |

| 017. | [01] | 09019-11290 | CAMSHAFT, INJECTIO | 22123-1700A |

| 018. | [01] | 09019-30020 | RING, CAMSHAFT ADJ | 22124-1160A |

| 019. | [3C] | 09019-40400 | PLATE, CAMSHAFT SH | 22885-6660A |

| 019. | [3C] | 09019-40290 | PLATE, CAMSHAFT SH | 22885-5840A |

| 019. | [3C] | 09019-40150 | PLATE, CAMSHAFT SH | 22129-1200A |

| 019. | [3C] | 09019-40140 | PLATE, CAMSHAFT SH | 22129-1190A |

| 019. | [3C] | 09019-40110 | PLATE, CAMSHAFT SH | 22885-5830A |

| 019. | [3C] | 09019-40060 | PLATE, CAMSHAFT SH | 22885-4950A |

| 019. | [3C] | 09019-40050 | PLATE, CAMSHAFT SH | 22885-4940A |

| 019. | [3C] | 09019-40040 | PLATE, CAMSHAFT SH | 22885-4930A |

| 019. | [3C] | 09019-40030 | PLATE, CAMSHAFT SH | 22885-4920A |

| 019. | [3C] | 09019-40020 | PLATE, CAMSHAFT SH | 22885-4910A |

| 019. | [3C] | 09019-40010 | PLATE, CAMSHAFT SH | 22885-4900A |

| 020. | [01] | 09020-10700 | COVER, BEARING | 22111-1600A |

| 021. | [01] | 09020-60150 | GASKET, BEARING CO | |

| 021. | [01] | 09020-60210 | GASKET, BEARING CO | 22847-2270A |

| 022. | [01] | 09021-20760 | RACK, CONTROL | 22113-1500A |

| 023. | [01] | 09021-50060 | SCREW, RACK GUIDE | 22811-4850A |

| 024. | [01] | 94914-03430 | O-RING | 22817-1420A |

| 025. | [02] | 09023-00050 | PLATE SET, VALVE H | 22109-1170A |

| 026. | [04] | 94914-02570 | O-RING | 22817-1260A |

| 027. | [02] | 94901-02470 | WASHER | 22847-1900A |

| 028. | [01] | 09027-01460 | COVER SUB-ASSY, IN | |

| 028. | [01] | 09027-01200 | COVER SUB-ASSY, IN | 22102-1200A |

| 028-001. | [02] | 09024-30030 | PACKING, AIR BLEED | 22847-1890A |

| 028-002. | [01] | 09027-20210 | GASKET, INJECTION | 22847-1990A |

| 028-003. | [01] | 09027-50182 | PROCESSING DRAWING | 22127-1210A |

| 028-004. | [02] | 09027-60030 | SCREW | 22815-1550A |

| 029. | [ C] | 09031-10100 | PLATE, TAPPET ADJU | 22885-1230A |

| 029. | [ C] | 09031-10110 | PLATE, TAPPET ADJU | 22885-1240A |

| 029. | [ C] | 09031-10120 | PLATE, TAPPET ADJU | 22885-1350A |

| 029. | [ C] | 09031-10130 | PLATE, TAPPET ADJU | 22885-1360A |

| 029. | [ C] | 09031-10140 | PLATE, TAPPET ADJU | 22885-1370A |

| 029. | [ C] | 09031-10150 | PLATE, TAPPET ADJU | 22885-1250A |

| 029. | [ C] | 09031-10290 | PLATE, TAPPET ADJU | 22885-2270A |

| 029. | [ C] | 09031-10090 | PLATE, TAPPET ADJU | 22885-1340A |

| 029. | [ C] | 09031-10080 | PLATE, TAPPET ADJU | 22885-1330A |

| 029. | [ C] | 09031-10070 | PLATE, TAPPET ADJU | 22885-1190A |

| 029. | [ C] | 09031-10060 | PLATE, TAPPET ADJU | 22885-1180A |

| 029. | [ C] | 09031-10050 | PLATE, TAPPET ADJU | 22885-1170A |

| 029. | [ C] | 09031-10040 | PLATE, TAPPET ADJU | 22885-1160A |

| 029. | [ C] | 09031-10030 | PLATE, TAPPET ADJU | 22885-1150A |

| 029. | [ C] | 09031-10020 | PLATE, TAPPET ADJU | 22885-1140A |

| 029. | [ C] | 09031-10010 | PLATE, TAPPET ADJU | 22885-1130A |

| 030. | [03] | 90160-06051 | NUT, HEXAGON | 22825-1480A |

| 031. | [03] | 90258-06001 | WASHER, SPRING | 28219-1110A |

| 032. | [04] | 94904-71360 | BOLT, W/WASHER | 22815-2500A |

| 033. | [01] | 94910-10120 | BEARING, ROLLER | 22837-1230A |

| 034. | [01] | 94910-10071 | BEARING, ROLLER | 22837-1100A |

| 035. | [01] | 94914-00380 | O-RING | 22817-1540A |

| 042. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | 22124-1090A |

| 043. | [02] | 94901-02490 | WASHER | 22877-1100A |

| 044. | [01] | 94918-00060 | SCREW, HOLLOW | 22835-1110A |

| 045. | [01] | 94918-00310 | SCREW, HOLLOW | 22835-1310A |

| 046. | [ C] | 09019-40410 | PLATE, CAMSHAFT SH | 22885-6670A |

| 046. | [ C] | 09019-40360 | PLATE, CAMSHAFT SH | 22885-5700A |

| 046. | [ C] | 09019-40350 | PLATE, CAMSHAFT SH | 22885-5690A |

| 046. | [ C] | 09019-40340 | PLATE, CAMSHAFT SH | 22885-5680A |

| 046. | [ C] | 09019-40170 | PLATE, CAMSHAFT SH | 22129-1180A |

| 046. | [ C] | 09019-40160 | PLATE, CAMSHAFT SH | 22129-1170A |

| 046. | [ C] | 09019-40100 | PLATE, CAMSHAFT SH | 22885-1580A |

| 046. | [ C] | 09019-40090 | PLATE, CAMSHAFT SH | 22885-1570A |

| 046. | [ C] | 09019-40080 | PLATE, CAMSHAFT SH | 22885-1560A |

| 046. | [ C] | 09019-40070 | PLATE, CAMSHAFT SH | 22885-1550A |

| 047. | [01] | 09069-11190 | BRACKET, STOP WIRE | 22343-4090A |

| 047. | [01] | 09069-11850 | BRACKET, STOP WIRE | |

| 048. | [01] | 94915-01620 | SEAL, OIL | 22827-1040A |

Include in #3:

09010-09281

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-09281 | 22110-2690 | BODY ASSY, INJECTI |

Information:

Driver Techniques

The manner in which a vehicle is operated can have a dramatic effect on fuel consumption. Operators can maximize fuel economy and engine life by practicing the techniques of using minimum power and low engine rpm. The 3176 can be programmed to ensure that the engine and vehicle are operated within specific limits for maximum fuel economy. (Refer to topic "Customer Specified Parameters" in this publication for information.)The "gear fast/run slow" concept is new to many in the trucking industry, but not to Caterpillar. Caterpillar engines are designed to operate at lower engine rpm (speed) and have demonstrated excellent fuel savings and longer service life when operated in this manner.Starting Out

Before start up, check all engine fluid levels, belts, hoses, and wiring harnesses. Simple checks can catch problems early and prevent costly highway breakdowns.Before engaging the starter, always depress the clutch to remove the transmission drag from the engine. In cold weather, depressing the clutch can make the difference between starting and not starting the engine.Below 40°F 5°C), the 3176 automatically idles at 1000 rpm. The vehicle inspection will usually provide sufficient time for the engine to warm-up enough for the 3176 to reduce engine rpm to the programmed low idle rpm.In warm weather, depressing the clutch produces faster starts and reduces battery drain. After starting, check for engine oil pressure and let the engine idle at less than 1000 rpm or at programmed low idle.Caterpillar truck engines do not require long warm-up times that waste fuel. The time it takes to conduct a walk-around-inspection of the vehicle and engine is usually sufficient warm-up time.A load can be applied to the engine after normal oil pressure is reached and the water temperature gauge begins to rise.To get the vehicle in motion, use a gear that will result in a smooth, easy start without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly to avoid jerky, interrupted starts and stops which put stress on the drive train and waste fuel.Keep engine rpm (speed) at a minimum. Use just enough rpm to pick up the next gear. This technique saves fuel and will not harm the engine.Progressive Shifting

Drive Line efficiency is best in the low to mid rpm range (1100 - 1600 rpm) of the engine due to reduced frictional losses of the engine, transmission and rear axles. When accelerating under normal level road conditions, the engine should be operated in this most efficient rpm range by using only enough power to pick up the next higher gear. This technique of upshifting at the lowest possible rpm is called "progressive shifting."Progressive shifting also reduces the time to accelerate to the desired vehicle speed. Top gear is reached sooner because engine rpm does not have to fall off as far to synchronize the gears of the transmission. The key to progressive shifting is to use minimum rpm, minimum power and upshift early while accelerating the truck.The 3176 can be programmed to limit engine acceleration above

The manner in which a vehicle is operated can have a dramatic effect on fuel consumption. Operators can maximize fuel economy and engine life by practicing the techniques of using minimum power and low engine rpm. The 3176 can be programmed to ensure that the engine and vehicle are operated within specific limits for maximum fuel economy. (Refer to topic "Customer Specified Parameters" in this publication for information.)The "gear fast/run slow" concept is new to many in the trucking industry, but not to Caterpillar. Caterpillar engines are designed to operate at lower engine rpm (speed) and have demonstrated excellent fuel savings and longer service life when operated in this manner.Starting Out

Before start up, check all engine fluid levels, belts, hoses, and wiring harnesses. Simple checks can catch problems early and prevent costly highway breakdowns.Before engaging the starter, always depress the clutch to remove the transmission drag from the engine. In cold weather, depressing the clutch can make the difference between starting and not starting the engine.Below 40°F 5°C), the 3176 automatically idles at 1000 rpm. The vehicle inspection will usually provide sufficient time for the engine to warm-up enough for the 3176 to reduce engine rpm to the programmed low idle rpm.In warm weather, depressing the clutch produces faster starts and reduces battery drain. After starting, check for engine oil pressure and let the engine idle at less than 1000 rpm or at programmed low idle.Caterpillar truck engines do not require long warm-up times that waste fuel. The time it takes to conduct a walk-around-inspection of the vehicle and engine is usually sufficient warm-up time.A load can be applied to the engine after normal oil pressure is reached and the water temperature gauge begins to rise.To get the vehicle in motion, use a gear that will result in a smooth, easy start without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly to avoid jerky, interrupted starts and stops which put stress on the drive train and waste fuel.Keep engine rpm (speed) at a minimum. Use just enough rpm to pick up the next gear. This technique saves fuel and will not harm the engine.Progressive Shifting

Drive Line efficiency is best in the low to mid rpm range (1100 - 1600 rpm) of the engine due to reduced frictional losses of the engine, transmission and rear axles. When accelerating under normal level road conditions, the engine should be operated in this most efficient rpm range by using only enough power to pick up the next higher gear. This technique of upshifting at the lowest possible rpm is called "progressive shifting."Progressive shifting also reduces the time to accelerate to the desired vehicle speed. Top gear is reached sooner because engine rpm does not have to fall off as far to synchronize the gears of the transmission. The key to progressive shifting is to use minimum rpm, minimum power and upshift early while accelerating the truck.The 3176 can be programmed to limit engine acceleration above