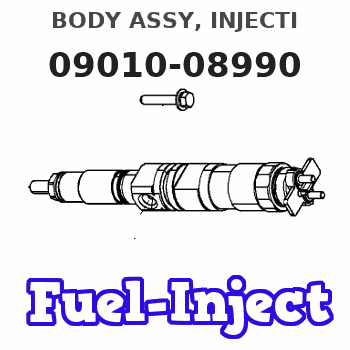

Information body assy, injecti

Rating:

KIT List:

| Body assy, injecti | 1904400320 |

| Body assy, injecti | 1904400320 |

| Body assy, injecti | 1904400320 |

Scheme ###:

| 000. | [01] | 09010-08990 | BODY ASSY, INJECTI | ME728237 |

| 001. | [01] | 19011-04640 | HOUSING KIT, INJEC | ME728368 |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | ME702091 |

| 003. | [04] | 09013-10420 | HOLDER, DELIVERY V | ME703579 |

| 004. | [04] | 09013-30140 | STOPPER, DELIVERY | ME703580 |

| 005. | [04] | 09013-60740 | SPRING, DELIVERY V | ME703055 |

| 006. | [04] | 09013-70110 | GASKET, DELIVERY V | ME702624 |

| 007. | [04] | 09014-01350 | VALVE SUB-ASSY, IN | ME703056 |

| 008. | [04] | 09015-03320 | ELEMENT SUB-ASSY, | ME703565 |

| 009. | [04] | 09015-60010 | PINION, PLUNGER CO | ME702058 |

| 010. | [04] | 09015-70010 | SCREW, PLUNGER CON | ME702059 |

| 011. | [04] | 09016-10330 | SLEEVE, PLUNGER CO | ME702060 |

| 012. | [04] | 09016-30010 | SEAT, SPRING, UPR | ME702061 |

| 012. | [04] | 09016-30191 | SEAT, SPRING, UPR | ME736080 |

| 013. | [04] | 09016-40320 | SPRING, PUMP PLUNG | ME728173 |

| 013. | [04] | 09016-40350 | SPRING, PUMP PLUNG | ME736081 |

| 014. | [04] | 09016-50160 | SEAT, SPRING, LWR | MM514055 |

| 015. | [04] | 09017-00070 | TAPPET SUB-ASSY,IN | ME702556 |

| 016. | [04] | 09018-90090 | PLUG, INJECTION PU | ME703276 |

| 017. | [01] | 09019-11020 | CAMSHAFT, INJECTIO | ME703058 |

| 018. | [01] | 09019-30020 | RING, CAMSHAFT ADJ | ME702074 |

| 019. | [3C] | 09019-40010 | PLATE, CAMSHAFT SH | ME702075 |

| 019. | [3C] | 09019-40400 | PLATE, CAMSHAFT SH | ME728352 |

| 019. | [3C] | 09019-40290 | PLATE, CAMSHAFT SH | ME703274 |

| 019. | [3C] | 09019-40150 | PLATE, CAMSHAFT SH | ME703273 |

| 019. | [3C] | 09019-40140 | PLATE, CAMSHAFT SH | ME703272 |

| 019. | [3C] | 09019-40110 | PLATE, CAMSHAFT SH | ME703583 |

| 019. | [3C] | 09019-40060 | PLATE, CAMSHAFT SH | ME022103 |

| 019. | [3C] | 09019-40050 | PLATE, CAMSHAFT SH | ME022102 |

| 019. | [3C] | 09019-40040 | PLATE, CAMSHAFT SH | ME022101 |

| 019. | [3C] | 09019-40030 | PLATE, CAMSHAFT SH | ME022100 |

| 019. | [3C] | 09019-40020 | PLATE, CAMSHAFT SH | ME022099 |

| 020. | [01] | 09020-10351 | COVER, BEARING | ME703059 |

| 021. | [01] | 09020-60150 | GASKET, BEARING CO | ME728350 |

| 022. | [01] | 09021-20441 | RACK, CONTROL | ME703731 |

| 023. | [01] | 09021-50060 | SCREW, RACK GUIDE | ME728163 |

| 024. | [04] | 09022-20070 | WASHER, FUEL PIPE | ME702217 |

| 025. | [02] | 09023-00050 | PLATE SET, VALVE H | ME702558 |

| 026. | [04] | 90801-10180 | O-RING | ME702649 |

| 027. | [02] | 09025-10010 | WASHER, INJECTION | ME702595 |

| 028. | [01] | 09027-01460 | COVER SUB-ASSY, IN | ME736539 |

| 028. | [01] | 09027-01200 | COVER SUB-ASSY, IN | ME703732 |

| 028-002. | [02] | 09024-30030 | PACKING, AIR BLEED | ME702057 |

| 028-003. | [02] | 09027-60030 | SCREW | ME703028 |

| 028-006. | [01] | 09027-50182 | PROCESSING DRAWING | ME703051 |

| 028-007. | [01] | 09027-20210 | GASKET, INJECTION | ME703052 |

| 029. | [4C] | 09031-10100 | PLATE, TAPPET ADJU | MM500308 |

| 029. | [4C] | 09031-10110 | PLATE, TAPPET ADJU | MM500309 |

| 029. | [4C] | 09031-10120 | PLATE, TAPPET ADJU | MM500310 |

| 029. | [4C] | 09031-10130 | PLATE, TAPPET ADJU | MM500311 |

| 029. | [4C] | 09031-10140 | PLATE, TAPPET ADJU | MM500312 |

| 029. | [4C] | 09031-10150 | PLATE, TAPPET ADJU | MM500313 |

| 029. | [4C] | 09031-10290 | PLATE, TAPPET ADJU | ME728060 |

| 029. | [4C] | 09031-10090 | PLATE, TAPPET ADJU | MM500307 |

| 029. | [4C] | 09031-10080 | PLATE, TAPPET ADJU | MM500306 |

| 029. | [4C] | 09031-10010 | PLATE, TAPPET ADJU | ME702559 |

| 029. | [4C] | 09031-10020 | PLATE, TAPPET ADJU | MM500300 |

| 029. | [4C] | 09031-10030 | PLATE, TAPPET ADJU | MM500301 |

| 029. | [4C] | 09031-10040 | PLATE, TAPPET ADJU | MM500302 |

| 029. | [4C] | 09031-10050 | PLATE, TAPPET ADJU | MM500303 |

| 029. | [4C] | 09031-10060 | PLATE, TAPPET ADJU | MM500304 |

| 029. | [4C] | 09031-10070 | PLATE, TAPPET ADJU | MM500305 |

| 030. | [03] | 90160-06051 | NUT, HEXAGON | ME702588 |

| 031. | [03] | 90258-06001 | WASHER, SPRING | ME702596 |

| 032. | [04] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 033. | [01] | 94910-10120 | BEARING, ROLLER | ME702096 |

| 034. | [01] | 09031-00220 | VALVE ASSY, OVERFL | ME702261 |

| 035. | [01] | 94914-00380 | O-RING | ME702097 |

| 036. | [01] | 94918-00060 | SCREW, HOLLOW | ME702598 |

| 037. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 043. | [01] | 94910-10071 | BEARING, ROLLER | ME702562 |

| 044. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | ME702073 |

| 046. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | ME703469 |

| 046. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | ME703468 |

| 046. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | ME703467 |

| 046. | [3C] | 09019-40170 | PLATE, CAMSHAFT SH | ME703271 |

| 046. | [3C] | 09019-40160 | PLATE, CAMSHAFT SH | ME703270 |

| 046. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | MM500694 |

| 046. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | MM500693 |

| 046. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | MM500692 |

| 046. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | ME702076 |

| 046. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH | ME728353 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-08990 | ME728237 | BODY ASSY, INJECTI | |

| ME728237 | MITSUBISHI | BODY ASSY, INJECTI |

Information:

After Storage

Test the main stator windings with a megohmmeter in the following situations: 1. Before initial startup of generator set.2. Every 3 months* if generator is operating in a humid environment.3. If generator has not been run under load for 3 months* or more.*This is a guideline only. It may be necessary to megger more frequently if environment is extremely humid, salty or if the last megger test was close to 1 megohm.The megohmmeter test is described in Service Manuals SENR2180 or SENR7968. A reading of 1 meghom or less indicates that the winding has absorbed too much moisture.To Remove Moisture

To remove moisture caused by high humidity, use one of the following methods to make the generator dry:1. Energize space heaters in generator if so equipped.2. Put the generator in an oven at a temperature of not more than 85°C (185°F) for four hours.

If an oven is used for drying, use a forced air type rather than a radiant type. Radiant ovens can cause localized overheating.

3. Space heaters of the same type used in marine applications, can be installed on generators. (See the Parts Book.) These heaters heat the windings to remove moisture and should be connected at all times in high humidity conditions whenever the generator is not running.4. Use a canvas enclosure around the generator and heating lamps to increase the temperature. Make an opening in the top for release of moisture.5. Send a low voltage current through the windings to increase the temperature of the windings. Do not exceed 85°C (185°F).If the megohmmeter test reads under 1 megohm after the drying or if it goes below 1 megohm shortly after drying, contact your Caterpillar dealer. The insulation has deteriorated and should be reconditioned.

Test the main stator windings with a megohmmeter in the following situations: 1. Before initial startup of generator set.2. Every 3 months* if generator is operating in a humid environment.3. If generator has not been run under load for 3 months* or more.*This is a guideline only. It may be necessary to megger more frequently if environment is extremely humid, salty or if the last megger test was close to 1 megohm.The megohmmeter test is described in Service Manuals SENR2180 or SENR7968. A reading of 1 meghom or less indicates that the winding has absorbed too much moisture.To Remove Moisture

To remove moisture caused by high humidity, use one of the following methods to make the generator dry:1. Energize space heaters in generator if so equipped.2. Put the generator in an oven at a temperature of not more than 85°C (185°F) for four hours.

If an oven is used for drying, use a forced air type rather than a radiant type. Radiant ovens can cause localized overheating.

3. Space heaters of the same type used in marine applications, can be installed on generators. (See the Parts Book.) These heaters heat the windings to remove moisture and should be connected at all times in high humidity conditions whenever the generator is not running.4. Use a canvas enclosure around the generator and heating lamps to increase the temperature. Make an opening in the top for release of moisture.5. Send a low voltage current through the windings to increase the temperature of the windings. Do not exceed 85°C (185°F).If the megohmmeter test reads under 1 megohm after the drying or if it goes below 1 megohm shortly after drying, contact your Caterpillar dealer. The insulation has deteriorated and should be reconditioned.