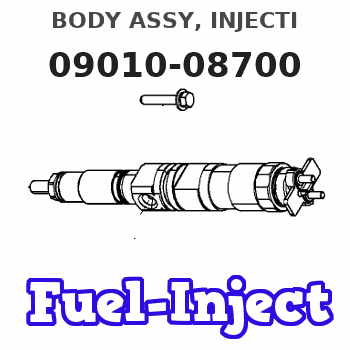

Information body assy, injecti

Rating:

KIT List:

| Body assy, injecti | 1904400320 |

| Body assy, injecti | 1904400320 |

| Body assy, injecti | 1904400320 |

| Body assy, injecti | 1904400320 |

| Body assy, injecti | 1904400320 |

Scheme ###:

| 000. | [01] | 09010-08700 | BODY ASSY, INJECTI | ME728131 |

| 001. | [01] | 19011-04500 | HOUSING KIT, INJEC | ME728351 |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | ME702091 |

| 003. | [04] | 09013-10710 | HOLDER, DELIVERY V | ME702050 |

| 004. | [04] | 09013-30261 | STOPPER, DELIVERY | ME702051 |

| 005. | [04] | 09013-60920 | SPRING, DELIVERY V | ME703729 |

| 006. | [04] | 09013-70100 | GASKET, DELIVERY V | ME702053 |

| 007. | [04] | 09014-01990 | VALVE SUB-ASSY, IN | ME703730 |

| 008. | [04] | 09015-04380 | ELEMENT SUB-ASSY, | ME728776 |

| 009. | [04] | 09015-60010 | PINION, PLUNGER CO | ME702058 |

| 010. | [04] | 09015-70010 | SCREW, PLUNGER CON | ME702059 |

| 011. | [04] | 09016-10330 | SLEEVE, PLUNGER CO | ME702060 |

| 012. | [04] | 09016-30191 | SEAT, SPRING, UPR | ME736080 |

| 012. | [04] | 09016-30010 | SEAT, SPRING, UPR | ME702061 |

| 013. | [04] | 09016-40320 | SPRING, PUMP PLUNG | ME728173 |

| 013. | [04] | 09016-40350 | SPRING, PUMP PLUNG | ME736081 |

| 014. | [04] | 09016-50160 | SEAT, SPRING, LWR | MM514055 |

| 015. | [04] | 09017-00070 | TAPPET SUB-ASSY,IN | ME702556 |

| 016. | [03] | 09018-90090 | PLUG, INJECTION PU | ME703276 |

| 017. | [01] | 09019-11020 | CAMSHAFT, INJECTIO | ME703058 |

| 018. | [01] | 09019-30020 | RING, CAMSHAFT ADJ | ME702074 |

| 019. | [ C] | 09019-40400 | PLATE, CAMSHAFT SH | ME728352 |

| 019. | [3C] | 09019-40290 | PLATE, CAMSHAFT SH | ME703274 |

| 019. | [3C] | 09019-40150 | PLATE, CAMSHAFT SH | ME703273 |

| 019. | [3C] | 09019-40140 | PLATE, CAMSHAFT SH | ME703272 |

| 019. | [3C] | 09019-40110 | PLATE, CAMSHAFT SH | ME703583 |

| 019. | [3C] | 09019-40060 | PLATE, CAMSHAFT SH | ME022103 |

| 019. | [3C] | 09019-40050 | PLATE, CAMSHAFT SH | ME022102 |

| 019. | [3C] | 09019-40040 | PLATE, CAMSHAFT SH | ME022101 |

| 019. | [3C] | 09019-40030 | PLATE, CAMSHAFT SH | ME022100 |

| 019. | [3C] | 09019-40020 | PLATE, CAMSHAFT SH | ME022099 |

| 019. | [3C] | 09019-40010 | PLATE, CAMSHAFT SH | ME728352 |

| 020. | [01] | 09020-10351 | COVER, BEARING | ME703059 |

| 021. | [01] | 09020-60150 | GASKET, BEARING CO | ME728350 |

| 021. | [01] | 09020-60040 | GASKET, BEARING CO | ME702078 |

| 022. | [01] | 09021-20441 | RACK, CONTROL | ME703731 |

| 023. | [01] | 09021-50060 | SCREW, RACK GUIDE | ME728163 |

| 024. | [04] | 09022-20070 | WASHER, FUEL PIPE | ME702217 |

| 025. | [02] | 09023-00050 | PLATE SET, VALVE H | ME702558 |

| 026. | [04] | 94914-02570 | O-RING | ME702098 |

| 027. | [02] | 09025-10010 | WASHER, INJECTION | ME702595 |

| 028. | [01] | 09027-01460 | COVER SUB-ASSY, IN | ME736539 |

| 028. | [01] | 09027-01200 | COVER SUB-ASSY, IN | ME703732 |

| 028-001. | [01] | 09027-50182 | PROCESSING DRAWING | ME703051 |

| 028-002. | [01] | 09027-20210 | GASKET, INJECTION | ME703052 |

| 028-003. | [02] | 09024-30030 | PACKING, AIR BLEED | ME702057 |

| 028-004. | [02] | 09027-60030 | SCREW | ME703028 |

| 029. | [4C] | 09031-10100 | PLATE, TAPPET ADJU | MM500308 |

| 029. | [4C] | 09031-10110 | PLATE, TAPPET ADJU | MM500309 |

| 029. | [4C] | 09031-10120 | PLATE, TAPPET ADJU | MM500310 |

| 029. | [4C] | 09031-10130 | PLATE, TAPPET ADJU | MM500311 |

| 029. | [4C] | 09031-10140 | PLATE, TAPPET ADJU | MM500312 |

| 029. | [4C] | 09031-10150 | PLATE, TAPPET ADJU | MM500313 |

| 029. | [4C] | 09031-10090 | PLATE, TAPPET ADJU | MM500307 |

| 029. | [4C] | 09031-10080 | PLATE, TAPPET ADJU | MM500306 |

| 029. | [4C] | 09031-10070 | PLATE, TAPPET ADJU | MM500305 |

| 029. | [4C] | 09031-10060 | PLATE, TAPPET ADJU | MM500304 |

| 029. | [4C] | 09031-10050 | PLATE, TAPPET ADJU | MM500303 |

| 029. | [4C] | 09031-10040 | PLATE, TAPPET ADJU | MM500302 |

| 029. | [4C] | 09031-10030 | PLATE, TAPPET ADJU | MM500301 |

| 029. | [4C] | 09031-10020 | PLATE, TAPPET ADJU | MM500300 |

| 029. | [4C] | 09031-10010 | PLATE, TAPPET ADJU | ME702559 |

| 029. | [4C] | 09031-10290 | PLATE, TAPPET ADJU | ME728060 |

| 030. | [03] | 90160-06051 | NUT, HEXAGON | ME702588 |

| 031. | [03] | 90258-06001 | WASHER, SPRING | ME702596 |

| 032. | [04] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 033. | [01] | 94910-10120 | BEARING, ROLLER | ME702096 |

| 034. | [01] | 09031-00310 | VALVE ASSY, OVERFL | ME703733 |

| 035. | [01] | 94914-00380 | O-RING | ME702097 |

| 036. | [01] | 94918-00060 | SCREW, HOLLOW | ME702598 |

| 037. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 043. | [01] | 94910-10071 | BEARING, ROLLER | ME702562 |

| 044. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | ME702073 |

| 045. | [3C] | 09019-40410 | PLATE, CAMSHAFT SH | ME728353 |

| 045. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | ME703469 |

| 045. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | ME703468 |

| 045. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | ME703467 |

| 045. | [3C] | 09019-40170 | PLATE, CAMSHAFT SH | ME703271 |

| 045. | [3C] | 09019-40160 | PLATE, CAMSHAFT SH | ME703270 |

| 045. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | MM500694 |

| 045. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | MM500693 |

| 045. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | MM500692 |

| 045. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | ME728353 |

| 046. | [01] | 07630-00660 | PICKUP ASSY, TACHO | ME016373 |

| 047. | [01] | 09221-70570 | NIPPLE, SWIVEL | ME728184 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-08700 | ME728131 | BODY ASSY, INJECTI | |

| ME728131 | MITSUBISHI | BODY ASSY, INJECTI |

Information:

Recommended Procedure With Chassis Dynamometer

Possible Causes/Corrections

1. Check Records Used To Determine Fuel ConsumptionMake sure the records are accurate. The minimum period for accurate fuel records is one month or 10,000 miles. Check the tires (air pressure and size), the gap between the tractor and trailer, air deflectors, trailer width, trailer type, engine cooling fan and driver habits. See "Owner/Operator Input" section for more information on the questions that should be asked.2. Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section.3. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting section of this Service Manual.4. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. See Special Instruction, Form No. SEHS8025 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Also, check for excessive exhaust smoke.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the correct procedures to use. Also refer back to the information learned earlier (see "Owner Operator Input" section) about truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.5. Worn Fuel NozzlesCheck the horsepower on a dynamometer as in Step 4 above. Make a replacement of the fuel injection nozzles and check the horsepower output again. If there is more than 10 hp difference the old nozzles had eroded orifices and were causing high fuel rate.An alternate test is to lower the fuel setting to get the correct hp output. If the fuel setting has to be reduced more than 0.25 mm (.010 in) below the fuel setting given on the Engine Information Plate, eroded nozzles are probably the cause and are the result of poor fuel filter maintenance. Installation of new nozzles and standard fuel settings are required to provide the proper fuel rate and hp.Recommended Procedure Without Chassis Dynamometer

Possible Causes/Corrections

1. Check Records Used To Determine Fuel ConsumptionMake sure the records are accurate. The minimum period for accurate fuel records is one month or 10,000 miles. Check the tires (air pressure and size), the gap between the tractor and trailer, air deflectors, trailer width, trailer type, engine cooling fan and driver habits. See "Owner/Operator Input" section for more information on the questions that should be asked.2. Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section.3. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual.4. Check Engine PerformanceInstall the tooling and follow the procedure given in the "Road Test" section.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for

Possible Causes/Corrections

1. Check Records Used To Determine Fuel ConsumptionMake sure the records are accurate. The minimum period for accurate fuel records is one month or 10,000 miles. Check the tires (air pressure and size), the gap between the tractor and trailer, air deflectors, trailer width, trailer type, engine cooling fan and driver habits. See "Owner/Operator Input" section for more information on the questions that should be asked.2. Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section.3. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting section of this Service Manual.4. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. See Special Instruction, Form No. SEHS8025 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Also, check for excessive exhaust smoke.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the correct procedures to use. Also refer back to the information learned earlier (see "Owner Operator Input" section) about truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.5. Worn Fuel NozzlesCheck the horsepower on a dynamometer as in Step 4 above. Make a replacement of the fuel injection nozzles and check the horsepower output again. If there is more than 10 hp difference the old nozzles had eroded orifices and were causing high fuel rate.An alternate test is to lower the fuel setting to get the correct hp output. If the fuel setting has to be reduced more than 0.25 mm (.010 in) below the fuel setting given on the Engine Information Plate, eroded nozzles are probably the cause and are the result of poor fuel filter maintenance. Installation of new nozzles and standard fuel settings are required to provide the proper fuel rate and hp.Recommended Procedure Without Chassis Dynamometer

Possible Causes/Corrections

1. Check Records Used To Determine Fuel ConsumptionMake sure the records are accurate. The minimum period for accurate fuel records is one month or 10,000 miles. Check the tires (air pressure and size), the gap between the tractor and trailer, air deflectors, trailer width, trailer type, engine cooling fan and driver habits. See "Owner/Operator Input" section for more information on the questions that should be asked.2. Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section.3. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual.4. Check Engine PerformanceInstall the tooling and follow the procedure given in the "Road Test" section.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for