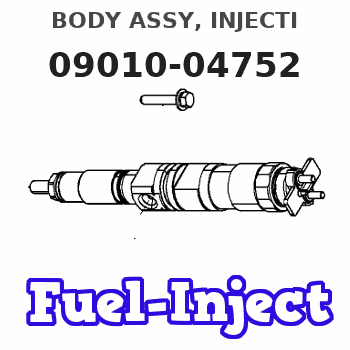

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-04752 | BODY ASSY, INJECTI | 09010-04750 |

| 001. | [01] | 19011-03121 | HOUSING KIT, INJEC | |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 85265-00057 |

| 003. | [04] | 09013-10540 | HOLDER, DELIVERY V | |

| 005. | [04] | 09013-60040 | SPRING, DELIVERY V | 09013-60040 |

| 006. | [04] | 09013-70010 | GASKET, DELIVERY V | 85265-00019 |

| 007. | [04] | 09014-00010 | VALVE SUB-ASSY, IN | 09014-00010 |

| 008. | [04] | 09015-00630 | ELEMENT SUB-ASSY, | |

| 009. | [04] | 09015-60010 | PINION, PLUNGER CO | 85265-00074 |

| 010. | [04] | 09015-70010 | SCREW, PLUNGER CON | 85265-00027 |

| 011. | [04] | 09016-10160 | SLEEVE, PLUNGER CO | 85265-00073 |

| 011. | [04] | 09016-10330 | SLEEVE, PLUNGER CO | |

| 012. | [04] | 09016-30010 | SEAT, SPRING, UPR | 09016-30010 |

| 012. | [04] | 09016-30191 | SEAT, SPRING, UPR | |

| 013. | [04] | 09016-40090 | SPRING, PUMP PLUNG | 09016-40090 |

| 014. | [04] | 09016-50160 | SEAT, SPRING, LWR | 09016-50160 |

| 015. | [04] | 09017-00070 | TAPPET SUB-ASSY,IN | 09017-00070 |

| 016. | [04] | 09018-90090 | PLUG, INJECTION PU | 09018-90090 |

| 016. | [04] | 09018-90060 | PLUG, INJECTION PU | 85265-00075 |

| 017. | [01] | 09019-10082 | CAMSHAFT, INJECTIO | 09019-10081 |

| 018. | [02] | 09019-30020 | RING, CAMSHAFT ADJ | 09019-30020 |

| 019. | [6C] | 09019-40150 | PLATE, CAMSHAFT SH | |

| 019. | [6C] | 09019-40140 | PLATE, CAMSHAFT SH | |

| 019. | [6C] | 09019-40060 | PLATE, CAMSHAFT SH | 09019-40060 |

| 019. | [6C] | 09019-40050 | PLATE, CAMSHAFT SH | 09019-40050 |

| 019. | [6C] | 09019-40040 | PLATE, CAMSHAFT SH | 09019-40040 |

| 019. | [6C] | 09019-40030 | PLATE, CAMSHAFT SH | 09019-40030 |

| 019. | [6C] | 09019-40020 | PLATE, CAMSHAFT SH | 09019-40020 |

| 019. | [6C] | 09019-40010 | PLATE, CAMSHAFT SH | 09019-40010 |

| 020. | [01] | 09020-10300 | COVER, BEARING | 09020-10300 |

| 021. | [01] | 09020-60160 | GASKET, BEARING CO | |

| 021. | [01] | 09020-60010 | GASKET, BEARING CO | 09020-60010 |

| 022. | [01] | 09021-20110 | RACK, CONTROL | |

| 023. | [01] | 09021-50011 | SCREW, RACK GUIDE | 09021-50011 |

| 023. | [01] | 09021-50060 | SCREW, RACK GUIDE | 09021-50060 |

| 024. | [02] | 09022-20070 | WASHER, FUEL PIPE | 85265-00079 |

| 025. | [02] | 09023-00031 | PLATE SET, VALVE H | 85265-00052 |

| 026. | [02] | 09024-00010 | BLEEDER SUB-ASSY, | 09024-00010 |

| 026. | [01] | 09024-00010 | BLEEDER SUB-ASSY, | 09024-00010 |

| 026-001. | [01] | 09024-10010 | WASHER, AIR BLEEDE | MM500486 |

| 026-002. | [01] | 09024-20010 | NIPPLE, AIR BLEEDE | 85265-00013 |

| 026-003. | [01] | 09024-30030 | PACKING, AIR BLEED | 85265-00016 |

| 026-004. | [01] | 09024-40010 | SCREW, AIR BLEEDER | 09024-40010 |

| 027. | [02] | 09025-10010 | WASHER, INJECTION | 85265-00077 |

| 028. | [01] | 09027-01090 | COVER SUB-ASSY, IN | |

| 028. | [01] | 09027-01460 | COVER SUB-ASSY, IN | |

| 028-001. | [01] | 09027-50182 | PROCESSING DRAWING | |

| 028-002. | [01] | 09027-20210 | GASKET, INJECTION | |

| 028-003. | [02] | 09024-30030 | PACKING, AIR BLEED | 85265-00016 |

| 028-004. | [02] | 09027-60030 | SCREW | |

| 029. | [4C] | 09031-10150 | PLATE, TAPPET ADJU | 09031-10150 |

| 029. | [4C] | 09031-10140 | PLATE, TAPPET ADJU | 09031-10140 |

| 029. | [4C] | 09031-10130 | PLATE, TAPPET ADJU | 09031-10130 |

| 029. | [4C] | 09031-10120 | PLATE, TAPPET ADJU | 09031-10120 |

| 029. | [4C] | 09031-10110 | PLATE, TAPPET ADJU | 09031-10110 |

| 029. | [4C] | 09031-10100 | PLATE, TAPPET ADJU | 09031-10100 |

| 029. | [4C] | 09031-10090 | PLATE, TAPPET ADJU | 09031-10090 |

| 029. | [4C] | 09031-10080 | PLATE, TAPPET ADJU | 09031-10080 |

| 029. | [4C] | 09031-10070 | PLATE, TAPPET ADJU | 09031-10070 |

| 029. | [4C] | 09031-10060 | PLATE, TAPPET ADJU | 09031-10060 |

| 029. | [4C] | 09031-10050 | PLATE, TAPPET ADJU | 09031-10050 |

| 029. | [4C] | 09031-10040 | PLATE, TAPPET ADJU | 09031-10040 |

| 029. | [4C] | 09031-10030 | PLATE, TAPPET ADJU | 09031-10030 |

| 029. | [4C] | 09031-10020 | PLATE, TAPPET ADJU | 09031-10020 |

| 029. | [4C] | 09031-10010 | PLATE, TAPPET ADJU | 09031-10010 |

| 030. | [03] | 90160-06051 | NUT, HEXAGON | 85265-00085 |

| 031. | [03] | 90258-06001 | WASHER, SPRING | 90258-06001 |

| 032. | [04] | 94904-71360 | BOLT, W/WASHER | 94904-71360 |

| 033. | [02] | 94910-10120 | BEARING, ROLLER | 94910-10121 |

| 034. | [01] | 94914-00060 | O-RING | 85265-00061 |

| 035. | [01] | 94914-00380 | O-RING | 85265-00084 |

| 036. | [01] | 94918-00060 | SCREW, HOLLOW | 85265-00076 |

| 037. | [01] | 94918-00310 | SCREW, HOLLOW | 85265-00078 |

Include in #3:

09010-04752

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-04752 | 09010-0475 | BODY ASSY, INJECTI |

Information:

Introduction

ReferenceSpecial Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)"This special instruction provides information for the installation of the Caterpillar Diesel Particulate Filter (DPF) on the machines that are listed above.Important notes regarding Engineered Solution DPF's:

Engineered Solution DPF's have been designed only for physical fit on the specified machine and serial number prefix. This does not mean that the temperature profile will be suitable for all like machines. Data logging is still necessary to ensure a suitable duty cycle for the DPF.

Serial number prefix is used to design, install, and field follow an Engineered Solution DPF. Parts are designed and Special Instructions are written based only on this serial number prefix.

Engineered Solution DPF's may fit on these other serial number prefixes with or without additional modifications and parts. CES has not installed the DPF on these other serial number prefixes and makes no guarantee of fit of the Engineered Solution DPF on them.Do not perform any procedure that is outlined in this special instruction or order any parts until you have a thorough understanding of the information that is contained in Special Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)" for important installation, general maintenance, testing, and cleaning information that is not included in this publication. Understanding the alarm operation and the maintenance requirements by the owner and the operator is important.The Caterpillar Diesel Particulate Filter includes the following: a particulate exhaust filter, an exhaust monitor, a thermocouple and parts needed for the installation. The Diesel Particulate Filter replaces the muffler. The Diesel Particulate Filter requires additional brackets and modifications for the installation.The Caterpillar DPF is used to reduce particulate matter, carbon monoxide, and hydrocarbons from diesel engine exhaust through catalytic oxidation and filtration. These filters are self-regenerating and do not need replaced. The filters will periodically burn off the accumulated soot. For this application, the following requirements must be met. Refer to the EPA web site for the latest verification requirements for Caterpillar Diesel Particulate Filter installations. Refer to Special Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)".

Ultra-Low Sulfur Diesel Fuel must be used. Ultra-Low Sulfur Diesel Fuel must have an average sulfur content of 15 ppm. The maximum sulfur content of the fuel must not exceed 30 parts per million (ppm).

The Exhaust Temperature of the engine must be greater than 240 °C (464 °F) for at least 40% of the time.

The ratio of emissions of Oxides of Nitrogen (NOx) to Particulate Matter must be a minimum of 25. This ratio should be higher for applications that involve a lower temperature. This technology is currently applicable to 1996 and newer engines.

The engine should be well maintained and the engine should not be consuming oil at an excessive rate (a rate that is greater than the engine

ReferenceSpecial Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)"This special instruction provides information for the installation of the Caterpillar Diesel Particulate Filter (DPF) on the machines that are listed above.Important notes regarding Engineered Solution DPF's:

Engineered Solution DPF's have been designed only for physical fit on the specified machine and serial number prefix. This does not mean that the temperature profile will be suitable for all like machines. Data logging is still necessary to ensure a suitable duty cycle for the DPF.

Serial number prefix is used to design, install, and field follow an Engineered Solution DPF. Parts are designed and Special Instructions are written based only on this serial number prefix.

Engineered Solution DPF's may fit on these other serial number prefixes with or without additional modifications and parts. CES has not installed the DPF on these other serial number prefixes and makes no guarantee of fit of the Engineered Solution DPF on them.Do not perform any procedure that is outlined in this special instruction or order any parts until you have a thorough understanding of the information that is contained in Special Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)" for important installation, general maintenance, testing, and cleaning information that is not included in this publication. Understanding the alarm operation and the maintenance requirements by the owner and the operator is important.The Caterpillar Diesel Particulate Filter includes the following: a particulate exhaust filter, an exhaust monitor, a thermocouple and parts needed for the installation. The Diesel Particulate Filter replaces the muffler. The Diesel Particulate Filter requires additional brackets and modifications for the installation.The Caterpillar DPF is used to reduce particulate matter, carbon monoxide, and hydrocarbons from diesel engine exhaust through catalytic oxidation and filtration. These filters are self-regenerating and do not need replaced. The filters will periodically burn off the accumulated soot. For this application, the following requirements must be met. Refer to the EPA web site for the latest verification requirements for Caterpillar Diesel Particulate Filter installations. Refer to Special Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)".

Ultra-Low Sulfur Diesel Fuel must be used. Ultra-Low Sulfur Diesel Fuel must have an average sulfur content of 15 ppm. The maximum sulfur content of the fuel must not exceed 30 parts per million (ppm).

The Exhaust Temperature of the engine must be greater than 240 °C (464 °F) for at least 40% of the time.

The ratio of emissions of Oxides of Nitrogen (NOx) to Particulate Matter must be a minimum of 25. This ratio should be higher for applications that involve a lower temperature. This technology is currently applicable to 1996 and newer engines.

The engine should be well maintained and the engine should not be consuming oil at an excessive rate (a rate that is greater than the engine