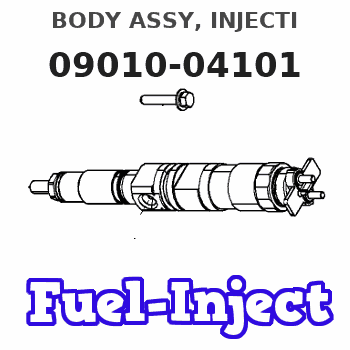

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-04101 | BODY ASSY, INJECTI | 22120-87603-000 |

| 001. | [01] | 19011-02650 | HOUSING KIT, INJEC | 22190-87603-000 |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 90099-04071-000 |

| 001-002. | [01] | 09022-10070 | UNION, INJECTION P | |

| 001-003. | [01] | 09022-10010 | UNION, INJECTION P | 22127-76010-000 |

| 001-003. | [01] | 09022-10310 | UNION, INJECTION P | |

| 002. | [01] | 09024-00010 | BLEEDER SUB-ASSY, | 22150-67010-000 |

| 003. | [04] | 09013-10010 | HOLDER, DELIVERY V | 22131-77020-000 |

| 004. | [04] | 09013-60050 | SPRING, DELIVERY V | 22148-46010-000 |

| 005. | [04] | 09013-70010 | GASKET, DELIVERY V | 22149-76010-000 |

| 006. | [04] | 09014-00010 | VALVE SUB-ASSY, IN | 22104-77020-000 |

| 007. | [04] | 09015-02280 | ELEMENT SUB-ASSY, | 22105-87303-000 |

| 008. | [04] | 09015-60010 | PINION, PLUNGER CO | 22155-76010-000 |

| 009. | [04] | 09015-70010 | SCREW, PLUNGER CON | 22156-76010-000 |

| 010. | [04] | 09016-10330 | SLEEVE, PLUNGER CO | 22142-58230-000 |

| 010. | [04] | 09016-10160 | SLEEVE, PLUNGER CO | 22142-77020-000 |

| 011. | [04] | 09016-30010 | SEAT, SPRING, UPR | 22143-77020-000 |

| 011. | [04] | 09016-30191 | SEAT, SPRING, UPR | 22143-78150-000 |

| 012. | [04] | 09016-40060 | SPRING, PUMP PLUNG | 22144-87301-000 |

| 013. | [04] | 09016-50010 | SEAT, SPRING, LWR | 22145-77020-000 |

| 014. | [04] | 09017-00020 | TAPPET SUB-ASSY,IN | 22106-77020-000 |

| 014. | [04] | 09017-00130 | TAPPET SUB-ASSY,IN | |

| 014-001. | [04] | 09017-10173 | TAPPET, INJECTION | |

| 014-002. | [04] | 09017-30010 | BOLT, INJECTION PU | 22134-77020-000 |

| 014-003. | [04] | 09017-40010 | NUT, INJECTION PUM | 22135-77020-000 |

| 014-004. | [04] | 09017-60010 | PIN, INJECTION PUM | 09017-60010-000 |

| 014-005. | [04] | 09017-80030 | BUSHING, INJECTION | |

| 014-006. | [04] | 09018-10030 | ROLLER, INJECTION | |

| 014-007. | [04] | 09017-50040 | SLIDER | |

| 014-008. | [04] | 09016-90110 | BODY, INJECTION PU | 22139-67022-000 |

| 015. | [03] | 09018-90090 | PLUG, INJECTION PU | 22157-87302-000 |

| 015. | [03] | 09018-90060 | PLUG, INJECTION PU | 22157-48023-000 |

| 016. | [01] | 09019-10082 | CAMSHAFT, INJECTIO | 22146-56010-000 |

| 017. | [02] | 09019-30020 | RING, CAMSHAFT ADJ | 22147-77020-000 |

| 018. | [6C] | 09019-40060 | PLATE, CAMSHAFT SH | 22166-76010-000 |

| 018. | [6C] | 09019-40050 | PLATE, CAMSHAFT SH | 22165-76010-000 |

| 018. | [6C] | 09019-40040 | PLATE, CAMSHAFT SH | 22164-76010-000 |

| 018. | [6C] | 09019-40030 | PLATE, CAMSHAFT SH | 22163-76010-000 |

| 018. | [6C] | 09019-40020 | PLATE, CAMSHAFT SH | 22162-76010-000 |

| 018. | [6C] | 09019-40010 | PLATE, CAMSHAFT SH | 22161-76010-000 |

| 019. | [01] | 09020-10390 | COVER, BEARING | 22111-87303-000 |

| 020. | [01] | 09021-20441 | RACK, CONTROL | 22114-48030-000 |

| 021. | [01] | 09021-50011 | SCREW, RACK GUIDE | 22115-77020-000 |

| 021. | [01] | 09021-50060 | SCREW, RACK GUIDE | 22115-78140-000 |

| 022. | [02] | 09022-20070 | WASHER, FUEL PIPE | 22125-87301-000 |

| 023. | [02] | 09023-00031 | PLATE SET, VALVE H | 22102-77021-000 |

| 029. | [01] | 09027-01090 | COVER SUB-ASSY, IN | 22103-48030-000 |

| 029-002. | [02] | 09024-30030 | PACKING, AIR BLEED | 22121-77020-000 |

| 029-003. | [02] | 09027-60030 | SCREW | |

| 029-006. | [01] | 09027-50182 | PROCESSING DRAWING | 22563-78050-000 |

| 029-007. | [01] | 09027-20210 | GASKET, INJECTION | 22153-78030-000 |

| 030. | [01] | 09020-60060 | GASKET, BEARING CO | 22195-68010-000 |

| 030. | [01] | 09020-60170 | GASKET, BEARING CO | 22195-87601-000 |

| 031. | [03] | 90160-06051 | NUT, HEXAGON | 94110-40600-000 |

| 032. | [03] | 90258-06001 | WASHER, SPRING | 94511-00600-000 |

| 033. | [04] | 91418-06201 | BOLT, W/WASHER | 91611-60620-000 |

| 034. | [02] | 94910-10120 | BEARING, ROLLER | 90091-30203-000 |

| 035. | [01] | 94914-03990 | O-RING | 90043-01065-000 |

| 036. | [01] | 94914-00380 | O-RING | 90099-14015-000 |

| 038. | [01] | 94918-00570 | SCREW, HOLLOW | |

| 039. | [01] | 94918-00310 | SCREW, HOLLOW | 90099-18010-000 |

| 043. | [01] | 07630-00071 | PICKUP ASSY, TACHO | 83275-87603-000 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-04101 | 22120-8760 | BODY ASSY, INJECTI |

Information:

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt diminishes as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only have stress in tension.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.If a part resists removal, check to be certain all nuts and bolts have been removed and that an adjacent part is not interfering.DISASSEMBLY AND ASSEMBLY: When servicing or repairing the engine, complete each step in turn. Do not partially assemble one part and start assembling some other part. Make all adjustments as recommended. Always check the job after it is completed to see nothing has been overlooked.BOLTS AND BOLT TORQUE: Use bolts of the correct length. A bolt which is too long may "bottom" before the head is tight against the part it is to hold and cause failure. The threads in the assembly can also become damaged when a "long" bolt is used.If a bolt is too short, there may not be enough threads to hold the part securely.Apply proper torque values to all bolts and nuts when assembling Caterpillar equipment. When a specific torque value is required, the value is given in the instructions. Tighten all other bolts and nuts for general usage or taperlock studs to the torque values given in the TORQUE SPECIFICATIONS. LOCKS: Lockwashers, flat metal locks or cotter pins are used to lock nuts and bolts.Flat metal locks must be installed properly to be effective. Bend one end of the lock around the edge of the part. Bend the other end against one flat surface of the nut or bolt head.Always install new locks in compartments which house moving parts.When installing lockwashers on housings made of aluminum, use a flat washer between the lockwasher and the housing.LINES AND WIRES: When removing or disconnecting a group of lines or wires, tag each one to assure proper assembly.LUBRICATION: Where applicable, fill the compartments of the components serviced with the amount, type and grade of lubricant recommended in the Lubrication Instructions. RUST PREVENTIVE COMPOUND: Clean the rust preventive compound from all machined surfaces of new parts before installing them.SHIMS: When shims are removed, tie them together and identify them as to location. Keep shims clean and flat until they are reinstalled.GASKETS: Be sure the holes in the gaskets correspond with the lubricant passages in the mating parts. If it is necessary to make gaskets, select stock of the proper type and thickness. Be sure to cut holes in the right places. Blank gaskets can cause serious damage.When removed, always install new cylinder head and manifold gaskets using recommended gasket compound on head gaskets to allow uniform sealing.