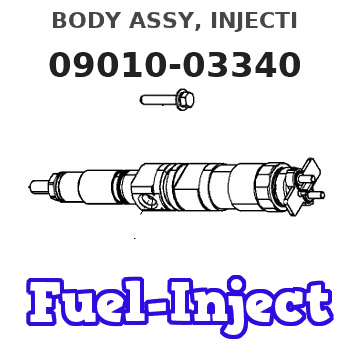

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-03340 | BODY ASSY, INJECTI | |

| 001. | [01] | 09010-91251 | HOUSING SUB-ASSY, | |

| 003. | [03] | 09013-10250 | HOLDER, DELIVERY V | |

| 004. | [03] | 09013-30010 | STOPPER, DELIVERY | 21702930 |

| 005. | [03] | 09013-60120 | SPRING, DELIVERY V | 21702860 |

| 006. | [03] | 09013-70110 | GASKET, DELIVERY V | |

| 007. | [3C] | 09013-50110 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50100 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50090 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50080 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50070 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50060 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50050 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50040 | RING, ADJUSTING | |

| 007. | [3C] | 09013-50030 | RING, ADJUSTING | 21702960 |

| 007. | [3C] | 09013-50020 | RING, ADJUSTING | 21702950 |

| 007. | [3C] | 09013-50010 | RING, ADJUSTING | 21702940 |

| 008. | [03] | 09014-00220 | VALVE SUB-ASSY, IN | 21702880 |

| 009. | [03] | 90801-10180 | O-RING | 21705250 |

| 009. | [03] | 94914-01140 | O-RING | 21702980 |

| 010. | [03] | 09015-00360 | ELEMENT SUB-ASSY, | 21702890 |

| 011. | [03] | 09015-60010 | PINION, PLUNGER CO | 21703220 |

| 012. | [03] | 09015-70010 | SCREW, PLUNGER CON | 21700130 |

| 013. | [03] | 09016-10330 | SLEEVE, PLUNGER CO | |

| 014. | [03] | 09016-30191 | SEAT, SPRING, UPR | |

| 015. | [03] | 09016-40150 | SPRING, PUMP PLUNG | 21703260 |

| 016. | [03] | 09016-50010 | SEAT, SPRING, LWR | 21700170 |

| 017. | [03] | 09017-00130 | TAPPET SUB-ASSY,IN | |

| 017. | [03] | 09017-00020 | TAPPET SUB-ASSY,IN | 21703140 |

| 017-001. | [04] | 09017-30010 | BOLT, INJECTION PU | 21703150 |

| 017-002. | [04] | 09017-40010 | NUT, INJECTION PUM | 21703160 |

| 017-003. | [04] | 09017-10173 | TAPPET, INJECTION | |

| 017-003. | [04] | 09016-90130 | BODY, INJECTION PU | |

| 017-003. | [04] | 09016-90110 | BODY, INJECTION PU | 21703170 |

| 017-004. | [04] | 09017-60010 | PIN, INJECTION PUM | 21703180 |

| 017-005. | [04] | 09018-10010 | ROLLER, INJECTION | 21703200 |

| 017-005. | [04] | 09018-10030 | ROLLER, INJECTION | |

| 017-006. | [04] | 09017-80030 | BUSHING, INJECTION | |

| 017-006. | [04] | 09017-80010 | BUSHING, INJECTION | 21703190 |

| 017-007. | [04] | 09017-50040 | SLIDER | |

| 018. | [03] | 09018-90060 | PLUG, INJECTION PU | 21706550 |

| 018. | [03] | 09018-90090 | PLUG, INJECTION PU | |

| 019. | [01] | 09019-10241 | CAMSHAFT, INJECTIO | 21703130 |

| 020. | [01] | 94915-01750 | SEAL, OIL | |

| 020. | [01] | 94915-00050 | SEAL, OIL | 21703330 |

| 021. | [02] | 94910-10120 | BEARING, ROLLER | 21706580 |

| 022. | [02] | 09019-30020 | RING, CAMSHAFT ADJ | 21703120 |

| 023. | [6C] | 09019-40150 | PLATE, CAMSHAFT SH | |

| 023. | [6C] | 09019-40140 | PLATE, CAMSHAFT SH | |

| 023. | [6C] | 09019-40060 | PLATE, CAMSHAFT SH | 21703100 |

| 023. | [6C] | 09019-40050 | PLATE, CAMSHAFT SH | 21703240 |

| 023. | [6C] | 09019-40040 | PLATE, CAMSHAFT SH | 21701050 |

| 023. | [6C] | 09019-40030 | PLATE, CAMSHAFT SH | 21703090 |

| 023. | [6C] | 09019-40020 | PLATE, CAMSHAFT SH | 21703080 |

| 023. | [6C] | 09019-40010 | PLATE, CAMSHAFT SH | 21703070 |

| 024. | [01] | 94914-00060 | O-RING | 21703340 |

| 024. | [02] | 94914-00060 | O-RING | 21703340 |

| 025. | [04] | 94904-71360 | BOLT, W/WASHER | 21706600 |

| 026. | [03] | 90258-06001 | WASHER, SPRING | |

| 027. | [01] | 09020-10240 | COVER, BEARING | 21706610 |

| 028. | [01] | 09021-20190 | RACK, CONTROL | 21703020 |

| 029. | [01] | 09021-50060 | SCREW, RACK GUIDE | |

| 034. | [01] | 09027-00520 | COVER SUB-ASSY, IN | 21703040 |

| 034. | [01] | 09027-01140 | COVER SUB-ASSY, IN | |

| 034. | [01] | 09027-01150 | COVER SUB-ASSY, IN | |

| 034-001. | [01] | 09027-50133 | PROCESSING DRAWING | |

| 034-002. | [01] | 09027-20200 | GASKET, INJECTION | |

| 034-003. | [02] | 09024-30030 | PACKING, AIR BLEED | 21703310 |

| 034-004. | [02] | 09027-60030 | SCREW | |

| 035. | [03] | 90160-06051 | NUT, HEXAGON | |

| 036. | [01] | 09023-00060 | PLATE SET, VALVE H | |

| 037. | [01] | 94918-00600 | SCREW, HOLLOW | 21703110 |

| 038. | [02] | 09025-10010 | WASHER, INJECTION | 21703050 |

| 048. | [01] | 09020-60160 | GASKET, BEARING CO |

Include in #3:

09010-03340

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-03340 | BODY ASSY, INJECTI |

Information:

Measuring Cleanliness

Fluid cleanliness can be measured by taking fluid samples from various machine compartments. Your Cat dealer can analyze the samples. Particle contaminants are typically measured by particle counters. Chemical contaminants can be measured by specific analysis techniques such as oxidation, water, or soot tests. Some chemical contaminants, such as water in fuel, can interfere with the particle counters and can be counted as particles. Refer to your Cat S O S lab or to your Cat dealer for more information.The number of particles in fluids is expressed in "ISO (International Organization for Standardization)" ratings. "ISO 4406" Standard classifies fluid cleanliness by the number and size of particles in 1 milliliter of fluid. "ISO 4406" Standard measures particle size in µm (microns) and reports the resulting count in three code ranges X, Y & Z. The three code range defines the size and distribution of particles in 1 milliliter of fluid:

The first code range, X represents the number of particles equal to or larger than 4 µm per milliliter of fluid.

The second code range, Y represents the number of particles equal to or larger than 6 µm per milliliter of fluid.

The third code range, Z represents the number of particles equal to or larger than 14 µm per milliliter of fluid.An example of an "ISO 4406" particle count is 18/16/13. Cat "ISO" cleanliness recommendations are expressed as two or three codes, depending on the machine system. The three code range follows "ISO 4406" definitions and is used for liquid fuels such as diesel and gasoline. The two code system, example "ISO -/16/13", is used for certain lubricant systems. In the two code system, the first number is the number of particles equal to or larger than 4 µm per milliliter of fluid. This number is not required and may be represented by a dash (-). The second number (Y) and the third number (Z) follow "ISO 4406" definitions. Cat reports the Y and Z codes for lubricating oils to keep consistency with older data and reports.An example of the particle size and distribution of the "ISO 4406" codes is given in Table 1.

Table 1

ISO 4406 Code Number of particles in 1 milliliter of fluid

4µm and up 6µm and up 14µm and up

"ISO 18/16/13" 1300 - 2500 320 - 640 40 - 80

"ISO 21/19/17" 10000 - 20000 2500 - 5000 80 - 160 Note: Several factors affect the results of particle counts. The factors include the cleanliness of the equipment used to obtain the sample, sample techniques, the cleanliness, and type of sample container, particle counter accuracy (calibration, maintenance, and process), and the environment where the sample is procured. Samples should be taken at representative locations in the fluid circulation system or the fluid distribution system when possible. The sample should be protected adequately from contamination during transport to the lab for analysis.In addition, particle counters may count water droplets and air bubbles as particulate contamination.Note: American Society for Testing and Measurement has developed "ASTM D7619" “Standard Test Method

Fluid cleanliness can be measured by taking fluid samples from various machine compartments. Your Cat dealer can analyze the samples. Particle contaminants are typically measured by particle counters. Chemical contaminants can be measured by specific analysis techniques such as oxidation, water, or soot tests. Some chemical contaminants, such as water in fuel, can interfere with the particle counters and can be counted as particles. Refer to your Cat S O S lab or to your Cat dealer for more information.The number of particles in fluids is expressed in "ISO (International Organization for Standardization)" ratings. "ISO 4406" Standard classifies fluid cleanliness by the number and size of particles in 1 milliliter of fluid. "ISO 4406" Standard measures particle size in µm (microns) and reports the resulting count in three code ranges X, Y & Z. The three code range defines the size and distribution of particles in 1 milliliter of fluid:

The first code range, X represents the number of particles equal to or larger than 4 µm per milliliter of fluid.

The second code range, Y represents the number of particles equal to or larger than 6 µm per milliliter of fluid.

The third code range, Z represents the number of particles equal to or larger than 14 µm per milliliter of fluid.An example of an "ISO 4406" particle count is 18/16/13. Cat "ISO" cleanliness recommendations are expressed as two or three codes, depending on the machine system. The three code range follows "ISO 4406" definitions and is used for liquid fuels such as diesel and gasoline. The two code system, example "ISO -/16/13", is used for certain lubricant systems. In the two code system, the first number is the number of particles equal to or larger than 4 µm per milliliter of fluid. This number is not required and may be represented by a dash (-). The second number (Y) and the third number (Z) follow "ISO 4406" definitions. Cat reports the Y and Z codes for lubricating oils to keep consistency with older data and reports.An example of the particle size and distribution of the "ISO 4406" codes is given in Table 1.

Table 1

ISO 4406 Code Number of particles in 1 milliliter of fluid

4µm and up 6µm and up 14µm and up

"ISO 18/16/13" 1300 - 2500 320 - 640 40 - 80

"ISO 21/19/17" 10000 - 20000 2500 - 5000 80 - 160 Note: Several factors affect the results of particle counts. The factors include the cleanliness of the equipment used to obtain the sample, sample techniques, the cleanliness, and type of sample container, particle counter accuracy (calibration, maintenance, and process), and the environment where the sample is procured. Samples should be taken at representative locations in the fluid circulation system or the fluid distribution system when possible. The sample should be protected adequately from contamination during transport to the lab for analysis.In addition, particle counters may count water droplets and air bubbles as particulate contamination.Note: American Society for Testing and Measurement has developed "ASTM D7619" “Standard Test Method