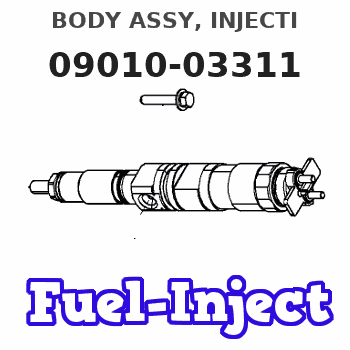

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-03311 | BODY ASSY, INJECTI | ME029071 |

| 001. | [01] | 19011-02770 | HOUSING KIT, INJEC | ME703937 |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | ME702091 |

| 003. | [06] | 09015-00030 | ELEMENT SUB-ASSY, | ME022597 |

| 004. | [06] | 09014-00061 | VALVE SUB-ASSY, IN | 90140-0061 |

| 005. | [06] | 09013-70010 | GASKET, DELIVERY V | ME022084 |

| 006. | [06] | 09013-60040 | SPRING, DELIVERY V | ME022617 |

| 007. | [06] | 09013-10010 | HOLDER, DELIVERY V | ME022081 |

| 008. | [01] | 09021-20010 | RACK, CONTROL | ME702079 |

| 009. | [01] | 09021-50060 | SCREW, RACK GUIDE | ME728163 |

| 010. | [06] | 09016-10160 | SLEEVE, PLUNGER CO | ME022134 |

| 010. | [06] | 09016-10330 | SLEEVE, PLUNGER CO | ME702060 |

| 011. | [06] | 09015-60010 | PINION, PLUNGER CO | ME702058 |

| 012. | [06] | 09015-70010 | SCREW, PLUNGER CON | ME702059 |

| 013. | [06] | 09016-30010 | SEAT, SPRING, UPR | ME702061 |

| 013. | [06] | 09016-30191 | SEAT, SPRING, UPR | ME736080 |

| 014. | [06] | 09016-40010 | SPRING, PUMP PLUNG | ME702062 |

| 015. | [06] | 09016-50010 | SEAT, SPRING, LWR | ME702063 |

| 016. | [06] | 09017-00130 | TAPPET SUB-ASSY,IN | ME702064 |

| 016-001. | [06] | 09016-90130 | BODY, INJECTION PU | ME702065 |

| 016-001. | [06] | 09017-10173 | TAPPET, INJECTION | |

| 016-002. | [06] | 09017-30010 | BOLT, INJECTION PU | ME702066 |

| 016-003. | [06] | 09017-40010 | NUT, INJECTION PUM | ME702067 |

| 016-004. | [06] | 09017-60010 | PIN, INJECTION PUM | ME702068 |

| 016-005. | [06] | 09017-80030 | BUSHING, INJECTION | ME702069 |

| 016-006. | [06] | 09018-10030 | ROLLER, INJECTION | ME702070 |

| 016-007. | [06] | 09017-50040 | SLIDER | ME736247 |

| 017. | [06] | 09018-90090 | PLUG, INJECTION PU | ME703276 |

| 018. | [01] | 09019-10152 | CAMSHAFT, INJECTIO | ME022137 |

| 020. | [02] | 94910-10120 | BEARING, ROLLER | ME702096 |

| 021. | [02] | 09019-30020 | RING, CAMSHAFT ADJ | ME702074 |

| 023. | [01] | 09020-10300 | COVER, BEARING | ME728839 |

| 025. | [03] | 90258-06001 | WASHER, SPRING | ME702596 |

| 029. | [01] | 09027-00622 | COVER SUB-ASSY, IN | 09027-00621 |

| 029. | [01] | 09027-00941 | COVER SUB-ASSY, IN | ME703939 |

| 029-002. | [02] | 09027-60030 | SCREW | ME703028 |

| 029-003. | [02] | 09024-30030 | PACKING, AIR BLEED | ME702057 |

| 029-006. | [01] | 09027-50083 | PROCESSING DRAWING | ME702602 |

| 029-007. | [01] | 09027-20220 | GASKET, INJECTION | ME702085 |

| 031. | [03] | 09023-00031 | PLATE SET, VALVE H | ME702082 |

| 034. | [03] | 90160-06051 | NUT, HEXAGON | ME702588 |

| 039. | [01] | 09036-10040 | BEARING, CENTER | ME702088 |

| 040. | [02] | 94900-66550 | SCREW | |

| 040. | [02] | 91050-05351 | SCREW, CROSSRECESS | ME702597 |

| 041. | [02] | 94901-81030 | WASHER, COPPER PLA | ME702094 |

| 043. | [01] | 09024-00010 | BLEEDER SUB-ASSY, | ME702083 |

| 043-001. | [01] | 09024-10010 | WASHER, AIR BLEEDE | ME702102 |

| 043-002. | [01] | 09024-20010 | NIPPLE, AIR BLEEDE | ME022094 |

| 043-003. | [01] | 09024-30030 | PACKING, AIR BLEED | ME702057 |

| 043-004. | [01] | 09024-40010 | SCREW, AIR BLEEDER | MM501930 |

| 047. | [01] | 94914-00380 | O-RING | ME702097 |

| 048. | [01] | 94918-00060 | SCREW, HOLLOW | ME702598 |

| 050. | [02] | 09025-10010 | WASHER, INJECTION | ME702595 |

| 051. | [6C] | 09019-40150 | PLATE, CAMSHAFT SH | ME703273 |

| 051. | [6C] | 09019-40110 | PLATE, CAMSHAFT SH | ME703583 |

| 051. | [6C] | 09019-40060 | PLATE, CAMSHAFT SH | ME022103 |

| 051. | [6C] | 09019-40050 | PLATE, CAMSHAFT SH | ME022102 |

| 051. | [6C] | 09019-40040 | PLATE, CAMSHAFT SH | ME022101 |

| 051. | [6C] | 09019-40030 | PLATE, CAMSHAFT SH | ME022100 |

| 051. | [6C] | 09019-40020 | PLATE, CAMSHAFT SH | ME022099 |

| 051. | [6C] | 09019-40010 | PLATE, CAMSHAFT SH | ME702075 |

| 052. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 053. | [02] | 09022-20070 | WASHER, FUEL PIPE | ME702217 |

| 054. | [04] | 94904-71360 | BOLT, W/WASHER | ME022507 |

| 055. | [01] | 09020-60010 | GASKET, BEARING CO | ME703584 |

| 055. | [01] | 09020-60160 | GASKET, BEARING CO | ME728820 |

Include in #3:

09010-03311

as BODY ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-03311 | ME029071 | BODY ASSY, INJECTI |

Information:

Introduction

This Special Instruction provides information for the installation of the Diesel Particulate Filter Monitoring System.System Description

The Diesel Particulate Filter (DPF) is placed on the engine in order to remove the soot and any particulate matter from the engine exhaust. A diagnostic module kit is also provided, and must be installed on the vehicle in order to properly monitor DPF health and functionality. Note: The diagnostic module kit is a required component of the DPF.The system monitors engine back pressure and exhaust temperature. The system also provides information to the driver and maintenance personnel on the performance of the DPF.The Diagnostic Module (DM) monitors and records levels of the exhaust back pressure and the exhaust temperature entering the Diesel Oxidation Catalyst module of the DPF. Data is recorded to permanent memory. The operator can download data. The operator can review data in order to determine functional history and maintenance history. Alarm levels can also be set to record incidents of excessive back pressure, excessive exhaust temperature, or other system failures. The system will allow the warning diagnostic lights to be illuminated in order to alert the operator of system problems.Important Safety Information

Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools in order to perform these functions properly. Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. If a tool, a procedure, a work method or operating technique that is not specifically recommended by Caterpillar is used, you must ensure that it is safe for you and for other people to use. You should ensure that the product will not be damaged or the product will not be made unsafe by the operation, lubrication, maintenance or the repair procedures that are used.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

Personal injury or death can result from improper assembly procedures.Do not attempt any assembly until you have read and understand the assembly instructions.

Parts List

Table 1

This Special Instruction provides information for the installation of the Diesel Particulate Filter Monitoring System.System Description

The Diesel Particulate Filter (DPF) is placed on the engine in order to remove the soot and any particulate matter from the engine exhaust. A diagnostic module kit is also provided, and must be installed on the vehicle in order to properly monitor DPF health and functionality. Note: The diagnostic module kit is a required component of the DPF.The system monitors engine back pressure and exhaust temperature. The system also provides information to the driver and maintenance personnel on the performance of the DPF.The Diagnostic Module (DM) monitors and records levels of the exhaust back pressure and the exhaust temperature entering the Diesel Oxidation Catalyst module of the DPF. Data is recorded to permanent memory. The operator can download data. The operator can review data in order to determine functional history and maintenance history. Alarm levels can also be set to record incidents of excessive back pressure, excessive exhaust temperature, or other system failures. The system will allow the warning diagnostic lights to be illuminated in order to alert the operator of system problems.Important Safety Information

Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools in order to perform these functions properly. Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. If a tool, a procedure, a work method or operating technique that is not specifically recommended by Caterpillar is used, you must ensure that it is safe for you and for other people to use. You should ensure that the product will not be damaged or the product will not be made unsafe by the operation, lubrication, maintenance or the repair procedures that are used.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

Personal injury or death can result from improper assembly procedures.Do not attempt any assembly until you have read and understand the assembly instructions.

Parts List

Table 1