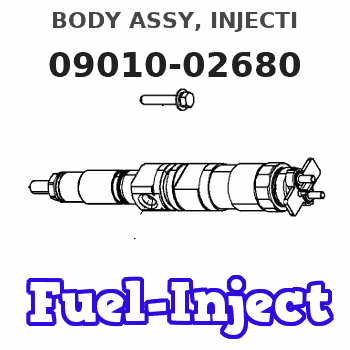

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-02680 | BODY ASSY, INJECTI | 30896-78002 |

| 001. | [01] | 19011-01390 | HOUSING KIT, INJEC | |

| 001-001. | [01] | 94904-30010 | BOLT, STUD | ME702091 |

| 002. | [06] | 09013-10010 | HOLDER, DELIVERY V | ME022081 |

| 003. | [06] | 09013-60040 | SPRING, DELIVERY V | ME022617 |

| 004. | [06] | 09013-70010 | GASKET, DELIVERY V | ME022084 |

| 005. | [06] | 09014-00021 | VALVE SUB-ASSY, IN | ME022085 |

| 006. | [06] | 09015-00030 | ELEMENT SUB-ASSY, | ME022597 |

| 007. | [06] | 09015-60010 | PINION, PLUNGER CO | ME702058 |

| 008. | [06] | 09015-70010 | SCREW, PLUNGER CON | ME702059 |

| 009. | [06] | 09016-10330 | SLEEVE, PLUNGER CO | ME702060 |

| 010. | [06] | 09016-30191 | SEAT, SPRING, UPR | ME736080 |

| 011. | [06] | 09016-40010 | SPRING, PUMP PLUNG | ME702062 |

| 012. | [06] | 09016-50010 | SEAT, SPRING, LWR | ME702063 |

| 013. | [06] | 09017-00020 | TAPPET SUB-ASSY,IN | 09017-00020 |

| 013. | [06] | 09017-00130 | TAPPET SUB-ASSY,IN | ME702064 |

| 013-001. | [06] | 09017-30010 | BOLT, INJECTION PU | ME702066 |

| 013-002. | [06] | 09017-40010 | NUT, INJECTION PUM | ME702067 |

| 013-003. | [06] | 09016-90110 | BODY, INJECTION PU | |

| 013-003. | [06] | 09016-90130 | BODY, INJECTION PU | ME702065 |

| 013-003. | [06] | 09017-10173 | TAPPET, INJECTION | |

| 013-004. | [06] | 09017-60010 | PIN, INJECTION PUM | ME702068 |

| 013-005. | [06] | 09017-80010 | BUSHING, INJECTION | ME022126 |

| 013-005. | [06] | 09017-80030 | BUSHING, INJECTION | ME702069 |

| 013-006. | [06] | 09018-10010 | ROLLER, INJECTION | ME022127 |

| 013-006. | [06] | 09018-10030 | ROLLER, INJECTION | ME702070 |

| 013-007. | [06] | 09017-50040 | SLIDER | ME736247 |

| 015. | [06] | 09018-90090 | PLUG, INJECTION PU | ME703276 |

| 016. | [01] | 09019-10440 | CAMSHAFT, INJECTIO | |

| 017. | [01] | 94915-00960 | SEAL, OIL | MM500730 |

| 018. | [01] | 94910-10121 | BEARING, ROLLER | ME702096 |

| 019. | [01] | 09019-30050 | RING, CAMSHAFT ADJ | ME702073 |

| 020. | [3C] | 09019-40150 | PLATE, CAMSHAFT SH | ME703273 |

| 020. | [3C] | 09019-40140 | PLATE, CAMSHAFT SH | ME703272 |

| 020. | [3C] | 09019-40110 | PLATE, CAMSHAFT SH | ME703583 |

| 020. | [3C] | 09019-40060 | PLATE, CAMSHAFT SH | ME022103 |

| 020. | [3C] | 09019-40050 | PLATE, CAMSHAFT SH | ME022102 |

| 020. | [3C] | 09019-40040 | PLATE, CAMSHAFT SH | ME022101 |

| 020. | [3C] | 09019-40030 | PLATE, CAMSHAFT SH | ME022100 |

| 020. | [3C] | 09019-40020 | PLATE, CAMSHAFT SH | ME022099 |

| 020. | [3C] | 09019-40010 | PLATE, CAMSHAFT SH | ME702075 |

| 021. | [01] | 94914-00060 | O-RING | MM500727 |

| 024. | [01] | 09020-10230 | COVER, BEARING | |

| 025. | [01] | 09021-20130 | RACK, CONTROL | ME728838 |

| 026. | [01] | 09021-50060 | SCREW, RACK GUIDE | ME728163 |

| 027. | [02] | 09022-20070 | WASHER, FUEL PIPE | ME702217 |

| 028. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 029. | [03] | 09023-00031 | PLATE SET, VALVE H | ME702082 |

| 030. | [02] | 09024-00010 | BLEEDER SUB-ASSY, | ME702083 |

| 030-001. | [02] | 09024-10010 | WASHER, AIR BLEEDE | ME702102 |

| 030-002. | [02] | 09024-20010 | NIPPLE, AIR BLEEDE | ME022094 |

| 030-003. | [02] | 09024-30030 | PACKING, AIR BLEED | ME702057 |

| 030-004. | [02] | 09024-40010 | SCREW, AIR BLEEDER | MM501930 |

| 031. | [01] | 19025-00060 | PIPE ASSY, OVERFLO | |

| 033. | [01] | 09024-80010 | WASHER, DRAIN SCRE | ME702175 |

| 034. | [01] | 09024-90010 | SCREW, DRAIN | ME022112 |

| 036. | [02] | 09025-10010 | WASHER, INJECTION | ME702595 |

| 037. | [01] | 94918-00600 | SCREW, HOLLOW | MM501002 |

| 038. | [01] | 94914-00380 | O-RING | ME702097 |

| 039. | [01] | 09029-00106 | GAUGE SUB-ASSY, IN | ME022421 |

| 041. | [01] | 09027-00412 | COVER SUB-ASSY, IN | 09027-00412 |

| 041-001. | [01] | 09027-10201 | PLATE, INJECTION P | |

| 041-002. | [01] | 09027-20220 | GASKET, INJECTION | ME702085 |

| 041-003. | [02] | 09024-30030 | PACKING, AIR BLEED | ME702057 |

| 041-004. | [02] | 09027-60030 | SCREW | ME703028 |

| 041-005. | [01] | 09028-00040 | CLEANER, INJECTION | ME022089 |

| 041-006. | [01] | 09024-10010 | WASHER, AIR BLEEDE | ME702102 |

| 042. | [01] | 09036-10040 | BEARING, CENTER | ME702088 |

| 043. | [02] | 09036-60021 | SCREW, GUIDE | ME022106 |

| 043. | [02] | 91050-05351 | SCREW, CROSSRECESS | ME702597 |

| 044. | [02] | 94901-81030 | WASHER, COPPER PLA | ME702094 |

| 046. | [04] | 94904-71360 | BOLT, W/WASHER | ME022507 |

| 051. | [01] | 94910-10071 | BEARING, ROLLER | ME702562 |

| 052. | [01] | 09019-30020 | RING, CAMSHAFT ADJ | ME702074 |

| 053. | [3C] | 09019-40360 | PLATE, CAMSHAFT SH | ME703469 |

| 053. | [3C] | 09019-40350 | PLATE, CAMSHAFT SH | ME703468 |

| 053. | [3C] | 09019-40340 | PLATE, CAMSHAFT SH | ME703467 |

| 053. | [3C] | 09019-40170 | PLATE, CAMSHAFT SH | ME703271 |

| 053. | [3C] | 09019-40160 | PLATE, CAMSHAFT SH | ME703270 |

| 053. | [3C] | 09019-40100 | PLATE, CAMSHAFT SH | MM500694 |

| 053. | [3C] | 09019-40090 | PLATE, CAMSHAFT SH | MM500693 |

| 053. | [3C] | 09019-40080 | PLATE, CAMSHAFT SH | MM500692 |

| 053. | [3C] | 09019-40070 | PLATE, CAMSHAFT SH | ME702076 |

| 054. | [01] | 94914-01550 | O-RING | MM500867 |

Include in #3:

09000-08910

as BODY ASSY, INJECTI

09010-02680

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-02680 | 30896-7800 | BODY ASSY, INJECTI | |

| 30896-78002 | MITSUBISHI | BODY ASSY, INJECTI |

Information:

DETERMINING WHEN TO OVERHAUL THE ENGINE

Generally, when to overhaul the engine is to be determined by taking into account a drop in compression pressure as well as an increase in lube oil consumption and excessive blowby gases. Lower power or loss of power, an increase in fuel consumption, a drop in lube oil pressure, hard starting and excessive abnormal noise are also troubles. These troubles, however, are not always the result of low compression pressure and give no valid reason for overhauling the engine.The engine develops troubles of widely different varieties when the compression pressure drops in it. Following are the typical troubles caused by the compression pressure failure:(1) Low power or loss of power(2) Increase in fuel consumption(3) Increase in lube oil consumption(4) Excessive blowby through breather due to worn cylinders, pistons, etc.(5) Excessive blowby due to poor seating of worn inlet and exhaust valves(6) Hard starting or failure to start(7) Excessive engine noiseIn most cases, these troubles occur concurrently. Some of them are directly caused by low compression pressure, but others are not. Among the troubles listed above, (2) and (6) are caused by a fuel injection pump improperly adjusted with respect to injection quantity or injection timing, worn injection pump plungers, faulty injection nozzles, or poor care of the battery, starter and alternator.The trouble to be taken into account as the most valid reason for overhauling the engine is (4): in actually determining when to overhaul the engine, it is reasonable to take this trouble into account in conjunction with the other ones.COMPRESSION PRESSURE MEASUREMENT

1. Inspection Check to make sure -(1) The crankcase oil level is correct, and the air cleaner, starter and battery are all in normal condition.(2) The engine is at the normal operating temperature.2. Measurement (1) Move the control lever to a position for shutting off fuel supply.(2) Remove all glow plugs from the engine. Install the compression gauge and adapter (ST332270) combination to a cylinder on which the compression pressure is to be measured.

Compression gauge and adaptor

Measuring compression pressure(3) Turn the engine with the starter and read the gauge pressure at the instant the gauge pointer comes to stop.(4) If the gauge reading is below the limit, overhaul the engine.

a) Be sure to measure the compression pressure on all cylinders.b) The compression pressure varies with change of engine rpm. This makes it necessary to check engine rpm at the time of measuring the compression pressure.

a) It is important to measure the compression pressure at regular intervals to obtain the data on the gradual change of the compression pressure.b) The compression pressure would be slightly higher than the standard in a new or overhauled engine owing to break-in of the piston rings, valve seats, etc. It drops as the engine components wear down.

TROUBLESHOOTING

1. GeneralThe diagnosis of troubles, especially those caused by a faulty fuel injection pump or injection nozzles, or low compression pressure, can be difficult. It requires a careful inspection to determine not which item is the cause, but how many

Generally, when to overhaul the engine is to be determined by taking into account a drop in compression pressure as well as an increase in lube oil consumption and excessive blowby gases. Lower power or loss of power, an increase in fuel consumption, a drop in lube oil pressure, hard starting and excessive abnormal noise are also troubles. These troubles, however, are not always the result of low compression pressure and give no valid reason for overhauling the engine.The engine develops troubles of widely different varieties when the compression pressure drops in it. Following are the typical troubles caused by the compression pressure failure:(1) Low power or loss of power(2) Increase in fuel consumption(3) Increase in lube oil consumption(4) Excessive blowby through breather due to worn cylinders, pistons, etc.(5) Excessive blowby due to poor seating of worn inlet and exhaust valves(6) Hard starting or failure to start(7) Excessive engine noiseIn most cases, these troubles occur concurrently. Some of them are directly caused by low compression pressure, but others are not. Among the troubles listed above, (2) and (6) are caused by a fuel injection pump improperly adjusted with respect to injection quantity or injection timing, worn injection pump plungers, faulty injection nozzles, or poor care of the battery, starter and alternator.The trouble to be taken into account as the most valid reason for overhauling the engine is (4): in actually determining when to overhaul the engine, it is reasonable to take this trouble into account in conjunction with the other ones.COMPRESSION PRESSURE MEASUREMENT

1. Inspection Check to make sure -(1) The crankcase oil level is correct, and the air cleaner, starter and battery are all in normal condition.(2) The engine is at the normal operating temperature.2. Measurement (1) Move the control lever to a position for shutting off fuel supply.(2) Remove all glow plugs from the engine. Install the compression gauge and adapter (ST332270) combination to a cylinder on which the compression pressure is to be measured.

Compression gauge and adaptor

Measuring compression pressure(3) Turn the engine with the starter and read the gauge pressure at the instant the gauge pointer comes to stop.(4) If the gauge reading is below the limit, overhaul the engine.

a) Be sure to measure the compression pressure on all cylinders.b) The compression pressure varies with change of engine rpm. This makes it necessary to check engine rpm at the time of measuring the compression pressure.

a) It is important to measure the compression pressure at regular intervals to obtain the data on the gradual change of the compression pressure.b) The compression pressure would be slightly higher than the standard in a new or overhauled engine owing to break-in of the piston rings, valve seats, etc. It drops as the engine components wear down.

TROUBLESHOOTING

1. GeneralThe diagnosis of troubles, especially those caused by a faulty fuel injection pump or injection nozzles, or low compression pressure, can be difficult. It requires a careful inspection to determine not which item is the cause, but how many