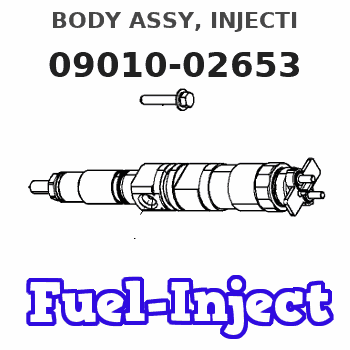

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-02653 | BODY ASSY, INJECTI | |

| 001. | [01] | 19011-00963 | HOUSING KIT, INJEC | 19011-00960 |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 85265-00057 |

| 003. | [04] | 09013-10010 | HOLDER, DELIVERY V | 09013-10010 |

| 004. | [04] | 09013-60040 | SPRING, DELIVERY V | 09013-60040 |

| 005. | [04] | 09013-70010 | GASKET, DELIVERY V | 85265-00019 |

| 006. | [04] | 09014-00010 | VALVE SUB-ASSY, IN | 09014-00010 |

| 007. | [04] | 09015-00350 | ELEMENT SUB-ASSY, | 09015-00350 |

| 008. | [04] | 09015-60010 | PINION, PLUNGER CO | 85265-00074 |

| 009. | [04] | 09015-70010 | SCREW, PLUNGER CON | 85265-00027 |

| 010. | [04] | 09016-10160 | SLEEVE, PLUNGER CO | 85265-00073 |

| 010. | [04] | 09016-10330 | SLEEVE, PLUNGER CO | |

| 011. | [04] | 09016-30010 | SEAT, SPRING, UPR | 09016-30010 |

| 011. | [04] | 09016-30191 | SEAT, SPRING, UPR | |

| 012. | [04] | 09016-40090 | SPRING, PUMP PLUNG | 09016-40090 |

| 013. | [04] | 09016-50160 | SEAT, SPRING, LWR | |

| 014. | [04] | 09017-00070 | TAPPET SUB-ASSY,IN | 09017-00070 |

| 016. | [04] | 09018-90090 | PLUG, INJECTION PU | 09018-90090 |

| 017. | [01] | 09019-10082 | CAMSHAFT, INJECTIO | 09019-10081 |

| 018. | [02] | 09019-30020 | RING, CAMSHAFT ADJ | 09019-30020 |

| 019. | [ C] | 09019-40400 | PLATE, CAMSHAFT SH | |

| 019. | [ C] | 09019-40290 | PLATE, CAMSHAFT SH | |

| 019. | [ C] | 09019-40150 | PLATE, CAMSHAFT SH | |

| 019. | [ C] | 09019-40140 | PLATE, CAMSHAFT SH | |

| 019. | [ C] | 09019-40110 | PLATE, CAMSHAFT SH | 09019-40110 |

| 019. | [ C] | 09019-40060 | PLATE, CAMSHAFT SH | 09019-40060 |

| 019. | [ C] | 09019-40050 | PLATE, CAMSHAFT SH | 09019-40050 |

| 019. | [ C] | 09019-40040 | PLATE, CAMSHAFT SH | 09019-40040 |

| 019. | [ C] | 09019-40030 | PLATE, CAMSHAFT SH | 09019-40030 |

| 019. | [ C] | 09019-40020 | PLATE, CAMSHAFT SH | 09019-40020 |

| 019. | [ C] | 09019-40010 | PLATE, CAMSHAFT SH | 09019-40010 |

| 020. | [02] | 94910-10120 | BEARING, ROLLER | 94910-10121 |

| 021. | [04] | 94904-71360 | BOLT, W/WASHER | 94904-71360 |

| 022. | [03] | 90258-06001 | WASHER, SPRING | 90258-06001 |

| 023. | [01] | 09021-20020 | RACK, CONTROL | 09021-20020 |

| 024. | [01] | 09021-50011 | SCREW, RACK GUIDE | 85265-00024 |

| 024. | [01] | 09021-50060 | SCREW, RACK GUIDE | 09021-50060 |

| 025. | [02] | 09022-20070 | WASHER, FUEL PIPE | 85265-00079 |

| 026. | [01] | 94918-00310 | SCREW, HOLLOW | 85265-00078 |

| 027. | [02] | 09023-00031 | PLATE SET, VALVE H | 85265-00052 |

| 028. | [01] | 09024-00010 | BLEEDER SUB-ASSY, | 09024-00010 |

| 028-001. | [01] | 09024-10010 | WASHER, AIR BLEEDE | 85265-00014 |

| 028-002. | [01] | 09024-20010 | NIPPLE, AIR BLEEDE | 85265-00013 |

| 028-003. | [01] | 09024-30030 | PACKING, AIR BLEED | 85265-00016 |

| 028-004. | [01] | 09024-40010 | SCREW, AIR BLEEDER | 09024-40010 |

| 030. | [01] | 94914-00380 | O-RING | |

| 031. | [01] | 09027-01090 | COVER SUB-ASSY, IN | |

| 031. | [01] | 09027-01460 | COVER SUB-ASSY, IN | |

| 031-001. | [01] | 09027-50182 | PROCESSING DRAWING | |

| 031-002. | [01] | 09027-20210 | GASKET, INJECTION | |

| 031-003. | [02] | 09024-30030 | PACKING, AIR BLEED | 85265-00016 |

| 031-004. | [02] | 09027-60020 | SCREW | 09027-60020 |

| 032. | [01] | 94918-00060 | SCREW, HOLLOW | 85265-00076 |

| 034. | [02] | 09025-10010 | WASHER, INJECTION | 85265-00077 |

| 036. | [01] | 09020-10300 | COVER, BEARING | 09020-10300 |

| 037. | [ C] | 09031-10100 | PLATE, TAPPET ADJU | 09031-10100 |

| 037. | [ C] | 09031-10110 | PLATE, TAPPET ADJU | 09031-10110 |

| 037. | [ C] | 09031-10120 | PLATE, TAPPET ADJU | 09031-10120 |

| 037. | [ C] | 09031-10130 | PLATE, TAPPET ADJU | 09031-10130 |

| 037. | [ C] | 09031-10140 | PLATE, TAPPET ADJU | 09031-10140 |

| 037. | [ C] | 09031-10150 | PLATE, TAPPET ADJU | 09031-10150 |

| 037. | [ C] | 09031-10290 | PLATE, TAPPET ADJU | |

| 037. | [ C] | 09031-10090 | PLATE, TAPPET ADJU | 09031-10090 |

| 037. | [ C] | 09031-10080 | PLATE, TAPPET ADJU | 09031-10080 |

| 037. | [ C] | 09031-10010 | PLATE, TAPPET ADJU | 09031-10010 |

| 037. | [ C] | 09031-10020 | PLATE, TAPPET ADJU | 09031-10020 |

| 037. | [ C] | 09031-10030 | PLATE, TAPPET ADJU | 09031-10030 |

| 037. | [ C] | 09031-10040 | PLATE, TAPPET ADJU | 09031-10040 |

| 037. | [ C] | 09031-10050 | PLATE, TAPPET ADJU | 09031-10050 |

| 037. | [ C] | 09031-10060 | PLATE, TAPPET ADJU | 09031-10060 |

| 037. | [ C] | 09031-10070 | PLATE, TAPPET ADJU | 09031-10070 |

| 042. | [03] | 90160-06051 | NUT, HEXAGON | 85265-00085 |

| 043. | [01] | 94914-00060 | O-RING | 85265-00061 |

| 044. | [01] | 09020-60010 | GASKET, BEARING CO | 09020-60010 |

| 044. | [01] | 09020-60160 | GASKET, BEARING CO |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-02653 | BODY ASSY, INJECTI |

Information:

Fuel Tank Lifting

The fuel tank lifting warning sign is located on the fuel tank.

Drain fuel tank before lifting unit. Lifting this unit when fuel is present in the tank could result in separation of the tank from the base and cause personal injury or death.

Clutch

The clutch warning label may be located on the clutch housing (if equipped). Rotating gears-finger or hand entanglement. Do not service until reading the operator's manual.Lifting the Generator Set

The warning label for lifting the generator set is located on the rail.

Improper lift rigging can allow load to tumble causing injury and damage. 1. Use adequate spreader bar as described because center of gravity is above base lift points.2. Attach four properly rated chains from base lift holes to spreader bar.3. Adjust chain lengths to position spreader bar over center symbol for level lift.4. Use single point center lift arch and 5N2171 Instruction Film when present.

Jumper Cable Connections

The warning label for jumper cable connections is located near the batteries.

Improper jumper cable connections can cause an explosion resulting in personal injury.Batteries may be located in separate compartments. When using jumper cables, always connect positive (+) cable to positive (+) terminal of battery connected to starter solenoid and negative (-) cable from external source to starter negative (-) terminal (if machine not equipped with starter negative terminal, connect to engine block.) Follow procedure in the operation manual.

Electrical Shock

The warning label for electrical shock is located on the control panel. High voltage can cause electrical shocks. Electrical shocks can cause personal injury or death. Avoid contacting electrical components or wiring.General Hazard Information

Attach a DO NOT OPERATE or similar warning tag to the start switch or controls before performing maintenance or repairing the engine. These tags, SEHS7332, are available from your Caterpillar dealer. When appropriate, attach the tags at the engine and at each operator's position. Disconnect starting controls when appropriate. Do not allow unauthorized personnel on, around or in the engine unit when it is being serviced.Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well ventilated area and, if in an enclosed area, vent the exhaust to the outside.Use caution when removing filler cap, grease fittings, pressure taps, breathers or drain plugs. Hold a rag over the cap or plug to prevent being sprayed or splashed by liquids under pressure.* Wear a hard hat, protective glasses, hearing protection and other protective equipment as required by job conditions.* Do not wear loose clothing or jewelry that can catch on controls or other parts of the engine.* Make certain all protective guards and covers are secured in place.* Use all cleaning solutions with care.* Never put maintenance fluids into glass containers since glass containers can break.* Report all needed repairs.UNLESS INSTRUCTED DIFFERENTLY, PERFORM ALL MAINTENANCE AS FOLLOWS:* Stop the engine.* Ensure the protective locks or controls are in the applied position.* Disconnect the batteries whenever performing any maintenance or before servicing the electrical system. If the

The fuel tank lifting warning sign is located on the fuel tank.

Drain fuel tank before lifting unit. Lifting this unit when fuel is present in the tank could result in separation of the tank from the base and cause personal injury or death.

Clutch

The clutch warning label may be located on the clutch housing (if equipped). Rotating gears-finger or hand entanglement. Do not service until reading the operator's manual.Lifting the Generator Set

The warning label for lifting the generator set is located on the rail.

Improper lift rigging can allow load to tumble causing injury and damage. 1. Use adequate spreader bar as described because center of gravity is above base lift points.2. Attach four properly rated chains from base lift holes to spreader bar.3. Adjust chain lengths to position spreader bar over center symbol for level lift.4. Use single point center lift arch and 5N2171 Instruction Film when present.

Jumper Cable Connections

The warning label for jumper cable connections is located near the batteries.

Improper jumper cable connections can cause an explosion resulting in personal injury.Batteries may be located in separate compartments. When using jumper cables, always connect positive (+) cable to positive (+) terminal of battery connected to starter solenoid and negative (-) cable from external source to starter negative (-) terminal (if machine not equipped with starter negative terminal, connect to engine block.) Follow procedure in the operation manual.

Electrical Shock

The warning label for electrical shock is located on the control panel. High voltage can cause electrical shocks. Electrical shocks can cause personal injury or death. Avoid contacting electrical components or wiring.General Hazard Information

Attach a DO NOT OPERATE or similar warning tag to the start switch or controls before performing maintenance or repairing the engine. These tags, SEHS7332, are available from your Caterpillar dealer. When appropriate, attach the tags at the engine and at each operator's position. Disconnect starting controls when appropriate. Do not allow unauthorized personnel on, around or in the engine unit when it is being serviced.Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well ventilated area and, if in an enclosed area, vent the exhaust to the outside.Use caution when removing filler cap, grease fittings, pressure taps, breathers or drain plugs. Hold a rag over the cap or plug to prevent being sprayed or splashed by liquids under pressure.* Wear a hard hat, protective glasses, hearing protection and other protective equipment as required by job conditions.* Do not wear loose clothing or jewelry that can catch on controls or other parts of the engine.* Make certain all protective guards and covers are secured in place.* Use all cleaning solutions with care.* Never put maintenance fluids into glass containers since glass containers can break.* Report all needed repairs.UNLESS INSTRUCTED DIFFERENTLY, PERFORM ALL MAINTENANCE AS FOLLOWS:* Stop the engine.* Ensure the protective locks or controls are in the applied position.* Disconnect the batteries whenever performing any maintenance or before servicing the electrical system. If the