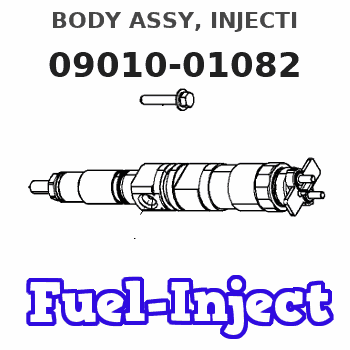

Information body assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09010-01082 | BODY ASSY, INJECTI | 22110-1530 |

| 001. | [01] | 09010-90602 | HOUSING SUB-ASSY, | 22101-1510 |

| 001-001. | [03] | 94904-30010 | BOLT, STUD | 22857-1060A |

| 002. | [06] | 09013-10020 | HOLDER, DELIVERY V | 6 053 1250 60 |

| 003. | [06] | 09013-60110 | SPRING, DELIVERY V | 22125-1070 |

| 004. | [06] | 09013-70010 | GASKET, DELIVERY V | 22847-1450 |

| 005. | [06] | 09014-00021 | VALVE SUB-ASSY, IN | 22103-1210 |

| 006. | [06] | 09015-00680 | ELEMENT SUB-ASSY, | 22104-1380 |

| 007. | [06] | 09015-60010 | PINION, PLUNGER CO | 22128-1020A |

| 008. | [06] | 09015-70010 | SCREW, PLUNGER CON | 22865-1280A |

| 009. | [06] | 09016-10330 | SLEEVE, PLUNGER CO | 22118-1310A |

| 010. | [06] | 09016-30191 | SEAT, SPRING, UPR | 22119-1190A |

| 011. | [06] | 09016-40010 | SPRING, PUMP PLUNG | 6 056 1200 80 |

| 012. | [06] | 09016-50010 | SEAT, SPRING, LWR | 22122-1060 |

| 013. | [06] | 09017-00020 | TAPPET SUB-ASSY,IN | 2210G-77020 |

| 013. | [06] | 09017-00130 | TAPPET SUB-ASSY,IN | 22105-1260 |

| 013-001. | [06] | 09017-30010 | BOLT, INJECTION PU | 0901H-30010 |

| 013-002. | [06] | 09017-40010 | NUT, INJECTION PUM | 6 053 1252 40 |

| 013-003. | [06] | 09016-90110 | BODY, INJECTION PU | 6 306 1205 20 |

| 013-003. | [06] | 09016-90130 | BODY, INJECTION PU | 22145-1010 |

| 013-003. | [06] | 09017-10173 | TAPPET, INJECTION | |

| 013-004. | [06] | 09017-60010 | PIN, INJECTION PUM | 22105-1130 |

| 013-005. | [06] | 09018-10010 | ROLLER, INJECTION | 22105-1140 |

| 013-005. | [06] | 09018-10030 | ROLLER, INJECTION | |

| 013-006. | [06] | 09017-80010 | BUSHING, INJECTION | 22105-1150 |

| 013-006. | [06] | 09017-80030 | BUSHING, INJECTION | |

| 013-007. | [06] | 09017-50040 | SLIDER | 6 306 1205 40 |

| 015. | [06] | 09018-90090 | PLUG, INJECTION PU | 22845-1420A |

| 016. | [01] | 09019-10220 | CAMSHAFT, INJECTIO | 22160-1020 |

| 017. | [01] | 94915-01750 | SEAL, OIL | 22823-1220 |

| 018. | [02] | 94910-10120 | BEARING, ROLLER | 22837-1230A |

| 019. | [02] | 09019-30020 | RING, CAMSHAFT ADJ | 22124-1160A |

| 020. | [6C] | 09019-40060 | PLATE, CAMSHAFT SH | 22885-4950A |

| 020. | [6C] | 09019-40050 | PLATE, CAMSHAFT SH | 22885-4940A |

| 020. | [6C] | 09019-40040 | PLATE, CAMSHAFT SH | 22885-4930A |

| 020. | [6C] | 09019-40030 | PLATE, CAMSHAFT SH | 22885-4920A |

| 020. | [6C] | 09019-40020 | PLATE, CAMSHAFT SH | 22885-4910A |

| 020. | [6C] | 09019-40010 | PLATE, CAMSHAFT SH | 22885-4900A |

| 021. | [02] | 94914-00060 | O-RING | 22813-1280 |

| 024. | [01] | 09020-10053 | COVER, BEARING | 6 053 1257 10 |

| 025. | [01] | 09021-20010 | RACK, CONTROL | 22113-1320A |

| 026. | [01] | 09021-50060 | SCREW, RACK GUIDE | 22811-4850A |

| 027. | [02] | 09022-20070 | WASHER, FUEL PIPE | 0 902 2200 70 |

| 027. | [02] | 09022-20010 | WASHER, FUEL PIPE | 22873-1240 |

| 028. | [01] | 94918-00310 | SCREW, HOLLOW | 22835-1310A |

| 029. | [03] | 09023-00031 | PLATE SET, VALVE H | 22109-1090A |

| 030. | [02] | 09024-00010 | BLEEDER SUB-ASSY, | 22106-1060 |

| 030-001. | [02] | 09024-10010 | WASHER, AIR BLEEDE | 22847-2150A |

| 030-002. | [02] | 09024-20010 | NIPPLE, AIR BLEEDE | 22873-1250 |

| 030-003. | [02] | 09024-30030 | PACKING, AIR BLEED | 22847-1890A |

| 030-004. | [02] | 09024-40010 | SCREW, AIR BLEEDER | 2211H-77020 |

| 033. | [01] | 09024-80010 | WASHER, DRAIN SCRE | 22847-1730A |

| 034. | [01] | 09024-90010 | SCREW, DRAIN | 6 053 1266 20 |

| 035. | [01] | 09025-00020 | NIPPLE SUB-ASSY, O | 6 056 1325 60 |

| 036. | [02] | 94901-02490 | WASHER | 22877-1100A |

| 037. | [01] | 94918-00060 | SCREW, HOLLOW | 22835-1110A |

| 037. | [01] | 94918-00600 | SCREW, HOLLOW | 22835-1100 |

| 038. | [01] | 94914-00380 | O-RING | 22817-1540A |

| 039. | [01] | 09029-00330 | GAUGE SUB-ASSY, IN | 22112-1110 |

| 041. | [01] | 09027-00840 | COVER SUB-ASSY, IN | 22102-1130 |

| 041-002. | [02] | 09024-30030 | PACKING, AIR BLEED | 22847-1890A |

| 041-003. | [02] | 09027-60030 | SCREW | 22815-1550A |

| 041-006. | [01] | 09024-10010 | WASHER, AIR BLEEDE | 22847-2150A |

| 041-007. | [01] | 09028-00040 | CLEANER, INJECTION | 0 902 8000 40 |

| 041-008. | [01] | 09027-10201 | PLATE, INJECTION P | |

| 041-009. | [01] | 09027-20220 | GASKET, INJECTION | 22847-2180A |

| 043. | [04] | 94904-71360 | BOLT, W/WASHER | 22815-2500A |

| 047. | [01] | 09036-10040 | BEARING, CENTER | 22837-1090A |

| 048. | [02] | 94900-66550 | SCREW | 22815-3250A |

| 049. | [02] | 94901-81030 | WASHER, COPPER PLA | 22867-1020A |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09010-01082 | 22110-1530 | BODY ASSY, INJECTI |

Information:

Disassembly of Water Pump

Inspection of Water Pump

If the inspection of the impeller and shaft finds abnormal noise or rough rotation, replace the assembly.

Inspection of impeller and shaft rotation conditionThermostat

Disassembly of Thermostat

Inspection of Thermostat

To test the thermostat operation, immerse the thermostat in a container filled with water, and heat the water while measuring the water temperature. Record the temperature at which the valve starts to open and the temperature at which the valve lift becomes 8 mm [0.3 in.] or more. (a) Stir the water in the container to ensure uniform temperature distribution.(b) When installing the thermostat, be sure to check the valve opening temperature indication stamped on the upper face of the thermostat mounting flange.

Inspection of thermostatThermo Switch

Inspection of Thermo Switch

Immerse the temperature sensor in oil, and measure the resistance while increasing the oil temperature. If the temperature measurement exceeds the standard value significantly, replace the thermo switch.

Since the inspection requires heating of oil to high temperatures, be careful not to get burns or start a fire.

Inspection of thermo switch

Inspection of Water Pump

If the inspection of the impeller and shaft finds abnormal noise or rough rotation, replace the assembly.

Inspection of impeller and shaft rotation conditionThermostat

Disassembly of Thermostat

Inspection of Thermostat

To test the thermostat operation, immerse the thermostat in a container filled with water, and heat the water while measuring the water temperature. Record the temperature at which the valve starts to open and the temperature at which the valve lift becomes 8 mm [0.3 in.] or more. (a) Stir the water in the container to ensure uniform temperature distribution.(b) When installing the thermostat, be sure to check the valve opening temperature indication stamped on the upper face of the thermostat mounting flange.

Inspection of thermostatThermo Switch

Inspection of Thermo Switch

Immerse the temperature sensor in oil, and measure the resistance while increasing the oil temperature. If the temperature measurement exceeds the standard value significantly, replace the thermo switch.

Since the inspection requires heating of oil to high temperatures, be careful not to get burns or start a fire.

Inspection of thermo switch