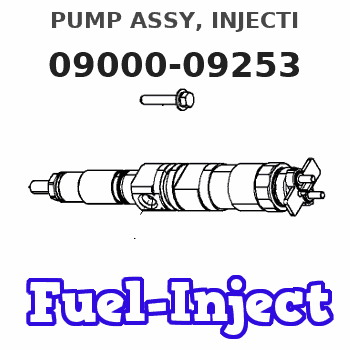

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09000-09253 |

| 002. | BODY ASSY, INJECTI | 09010-02750 |

| 003. | COVER, BEARING | 09020-10053 |

| 004. | BODY ASSY, INJECTI | 09010-04610 |

| 005. | TIMER ASSY, AUTOMA | 09180-00690 |

| 006. | PUMP ASSY, FUEL FE | 09210-00820 |

| 007. | PUMP ASSY, FUEL FE | 09210-00930 |

| 008. | COUPLING ASSY | 09250-00192 |

Scheme ###:

| 000. | [01] | 09000-09253 | PUMP ASSY, INJECTI | 22010-1511 |

| 006. | [01] | 09010-02750 | BODY ASSY, INJECTI | 22120-1040 |

| 006. | [01] | 09010-04610 | BODY ASSY, INJECTI | |

| 007. | [01] | 09080-03761 | GOVERNOR ASSY, MEC | 22310-1041 |

| 008. | [06] | 94904-70620 | BOLT, W/WASHER | 22815-1620A |

| 009. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 011. | [01] | 09001-80120 | COVER, CONTROL RAC | 22371-1170A |

| 012. | [01] | 09180-00690 | TIMER ASSY, AUTOMA | 6 305 1401 40 |

| 013. | [01] | 09001-20010 | NUT, TIMER ROUND | 22353-1050A |

| 014. | [01] | 94913-00050 | KEY, WOODRUFF | 22891-1040A |

| 015. | [01] | 90258-12001 | WASHER, SPRING | 22873-1310A |

| 016. | [01] | 09210-00820 | PUMP ASSY, FUEL FE | 22570-1020 |

| 016. | [01] | 09210-00930 | PUMP ASSY, FUEL FE | 22570-1040A |

| 017. | [01] | 09006-10011 | COVER, PRIMING PUM | 6 053 1552 60 |

| 018. | [01] | 09250-00192 | COUPLING ASSY | 22630-1010A |

| 020. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 022. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 023. | [03] | 90160-06051 | NUT, HEXAGON | 22825-1480A |

| 024. | [03] | 90258-06001 | WASHER, SPRING | 28219-1110A |

Include in #3:

09000-09253

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09000-09253 | 22010-1511 | PUMP ASSY, INJECTI |

Information:

Weekly (Before Starting Engine)

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Battery Charger - Check for proper operation Batteries - Clean/Check electrolyte level Air Starter System (if equipped) - Check lubricator oil level, air pressure and drain condensation Engine Air Cleaner - Check service indicator Block Heater - Check for proper operation, maintain 32°C (90°F) temperature Aftercooler - Inspect ATAAC Belts - Inspect/Replace Engine Protection Devices - Inspect system and gauges for proper operation Generator and Control Panel - Inspect componentsWeekly (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections and generator louvers for proper operation Engine Crankcase - Check oil level Oil Pressure - Check gauge reading Generator - Check frequency (rpm) and generated voltageWeekly (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Automatic Switches - Check for proper position to execute auto-start Battery Charger - Record charging amperage readingYearly (Before Starting Engine)*

Cooling System - Check coolant level, Test for concentration of supplemental coolant additive Crankcase Breather - Clean Valve Lash - Check/Adjust Governor - Inspect for leaks Governor Linkage - Check/Adjust and Lubricate Air Inlet Piping - Inspect Engine Air Cleaner - Check service indicator, Replace element if necessary Generator - Lubricate bearingYearly (With Engine Running)*

Engine Protection Devices - Inspect system and gauges for proper operation;/bs/, Record gauge readings Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate the engine at a minimum of 30 percent of rated load for minimum of two hours Engine Mounts - InspectYearly (After Stopping Engine)*

Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - ReplaceEvery Three Years (Before Starting Engine)*

Turbocharger - Inspect/Check bearing end play and radial clearance Governor - Inspect for leaks Thermostat - Replace Coolant Hoses - Replace Cooling System - Clean/Flush coolant Batteries - ReplaceEvery Three Years (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Protection Devices - Inspect system and gauges for proper operation, Record gauge readings Engine Crankcase - Check oil level Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate at a minimum of 30 percent of rated load for minimum of two hours Exhaust System - Check for leaksEvery Three Years (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - Replace Battery Charger - Record charging amp reading Automatic Switches - Check for proper position to execute auto-start Coolant Analysis - ObtainEvery Four Years

Drain/Replace Engine Coolant (Extended Life Coolant Only)*First Perform Previous Maintenance Items

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Battery Charger - Check for proper operation Batteries - Clean/Check electrolyte level Air Starter System (if equipped) - Check lubricator oil level, air pressure and drain condensation Engine Air Cleaner - Check service indicator Block Heater - Check for proper operation, maintain 32°C (90°F) temperature Aftercooler - Inspect ATAAC Belts - Inspect/Replace Engine Protection Devices - Inspect system and gauges for proper operation Generator and Control Panel - Inspect componentsWeekly (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections and generator louvers for proper operation Engine Crankcase - Check oil level Oil Pressure - Check gauge reading Generator - Check frequency (rpm) and generated voltageWeekly (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Automatic Switches - Check for proper position to execute auto-start Battery Charger - Record charging amperage readingYearly (Before Starting Engine)*

Cooling System - Check coolant level, Test for concentration of supplemental coolant additive Crankcase Breather - Clean Valve Lash - Check/Adjust Governor - Inspect for leaks Governor Linkage - Check/Adjust and Lubricate Air Inlet Piping - Inspect Engine Air Cleaner - Check service indicator, Replace element if necessary Generator - Lubricate bearingYearly (With Engine Running)*

Engine Protection Devices - Inspect system and gauges for proper operation;/bs/, Record gauge readings Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate the engine at a minimum of 30 percent of rated load for minimum of two hours Engine Mounts - InspectYearly (After Stopping Engine)*

Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - ReplaceEvery Three Years (Before Starting Engine)*

Turbocharger - Inspect/Check bearing end play and radial clearance Governor - Inspect for leaks Thermostat - Replace Coolant Hoses - Replace Cooling System - Clean/Flush coolant Batteries - ReplaceEvery Three Years (With Engine Running)*

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Protection Devices - Inspect system and gauges for proper operation, Record gauge readings Engine Crankcase - Check oil level Radiator (If Equipped) - Inspect for leaks and loose connections and louvers for proper operation Load Test - Operate at a minimum of 30 percent of rated load for minimum of two hours Exhaust System - Check for leaksEvery Three Years (After Stopping Engine)*

Walk-Around Inspection - Inspect engine and report malfunction and make necessary repairs Scheduled Oil Sampling (S O S) Analysis - Obtain Engine Oil and Filters - Replace Battery Charger - Record charging amp reading Automatic Switches - Check for proper position to execute auto-start Coolant Analysis - ObtainEvery Four Years

Drain/Replace Engine Coolant (Extended Life Coolant Only)*First Perform Previous Maintenance Items