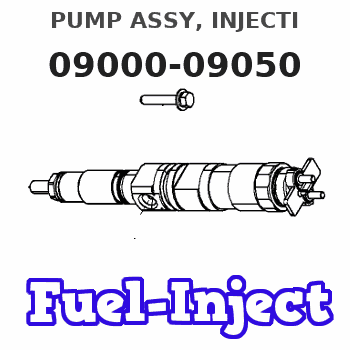

Information pump assy, injecti

Nozzle:

0935000970

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09000-09050 |

| 002. | BODY ASSY, INJECTI | 09010-00153 |

| 003. | TIMER ASSY, AUTOMA | 09180-00730 |

| 004. | PUMP ASSY, FUEL FE | 09210-00042 |

| 005. | COUPLING ASSY | 09240-00161 |

Scheme ###:

| 000. | [01] | 09000-09050 | PUMP ASSY, INJECTI | 22100-77081 |

| 001. | [01] | 09010-00153 | BODY ASSY, INJECTI | 22120-77020 |

| 002. | [01] | 09050-00212 | GOVERNOR ASSY, INJ | 22310-77081 |

| 003. | [01] | 09210-00042 | PUMP ASSY, FUEL FE | 22510-46010 |

| 004. | [01] | 09180-00730 | TIMER ASSY, AUTOMA | 22610-77052 |

| 005. | [01] | 09243-60020 | COUPLING, INJECTIO | 22632-66010 |

| 006. | [01] | 09240-00161 | COUPLING ASSY | 22630-77051 |

| 012. | [01] | 09001-80010 | COVER, CONTROL RAC | 22116-77020 |

| 013. | [01] | 94913-00050 | KEY, WOODRUFF | 90099-13002 |

| 014. | [01] | 90258-12001 | WASHER, SPRING | 94511-01200 |

| 015. | [01] | 09001-20010 | NUT, TIMER ROUND | 22611-77020 |

| 019. | [04] | 90258-06001 | WASHER, SPRING | 94511-00600 |

| 021. | [01] | 09006-10011 | COVER, PRIMING PUM | 22511-77020 |

| 023. | [04] | 94904-10121 | BOLT, SLOTTED HEXA | 90099-04036 |

| 023. | [04] | 91518-06161 | BOLT, W/WASHER | 90091-20611 |

| 024. | [01] | 91518-08221 | BOLT, W/WASHER | 90091-20804 |

| 025. | [01] | 09430-00012 | BOX ASSY, ENGINE S | 22340-77051 |

| 026. | [01] | 90258-08001 | WASHER, SPRING | 94511-00800 |

| 027. | [01] | 09048-10010 | CLAMP, HOSE | 22172-77121 |

| 028. | [02] | 90258-05001 | WASHER, SPRING | 90032-04023 |

| 029. | [02] | 91107-05081 | BOLT, HEXAGON | 90091-00597 |

Include in #3:

09000-09050

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09000-09050 | 22100-7708 | PUMP ASSY, INJECTI | |

| 22100-77081 | TOYOTA | PUMP ASSY, INJECTI |

Information:

1. Overview of Radiator-Equipped Engine's Cooling System

Flow of coolant2. Water Pump

2.1 Removal and Inspection

Removal sequence and points to check on water pump1 Cooling fan2 Water pump pulley3 Fan belt4 Water bypass hose5 Water pump assembly KEY POINTS FOR REMOVALRemoval of the water pump pulley and fan belt is possible after loosening slightly both the nut (1) on the alternator support bolt and the adjusting bolt (2). This allows the alternator to be moved and then the V-belt slackened.

Removing water pump pulley KEY POINTS FOR INSPECTIONTurn the pump by hand to check the impeller and shaft for smooth and quiet rotation. If irregular or noisy rotation is detected, replace them as an assembly.

Inspecting impeller and shaft rotation2.2 Installation

Correct locations of water pump mounting bolts KEY POINTS FOR INSPECTION(1) Install the six water pump mounting bolts in their correct locations by referring to the figure on the right for the nominal diameters and lengths from bottom of head.(2) Use a new gasket when installing the water pump.(3) Adjust the fan belt tension according to the following specification.

Fan belt tension adjustment

Unit: mm (in.)3. Thermostat

3.1 Disassembly

Removal sequence and points to check on thermostat1 Water outlet fitting2 Thermostat3 Thermostat fitting4 Water joint5 Temperature joint6 Thermounit3.2 Inspection KEY POINTS FOR INSPECTION(1) Operation Test of ThermostatPut the thermostat in a container of water. Heat the water and record both of the temperatures at which the valve starts to open and at which the valve lift reaches 8 mm (0.3 in.). If the readings do not conform to the specification below, replace the thermostat.

Carry out this operation with extreme care to avoid burns and prevent fire.

Operation test of thermostat(2) Thermounit InspectionPlace the temperature sensing section of the thermounit in a container of oil. Heat the oil to a temperature in each of the ranges shown below and measure the resistance between the terminal and body for each of the temperature. If the resistances are largely different from those specified below, replace the thermounit.

Unit: Ohms

Carry out this operation with extreme care to avoid burns and prevent fire.

Thermounit inspection3.3 InstallationExcept that the instructions shown below are to be followed, perform installation by following the removal sequence in reverse. KEY POINTS FOR INSTALLATION(1) Temperature jointApply sealant to the threads and tighten to the specified torque. (2) ThermostatMake sure that the thermostat flange is correctly fit into the counterbore in the intake manifold.

Installing temperature joint

Installing thermostat

Flow of coolant2. Water Pump

2.1 Removal and Inspection

Removal sequence and points to check on water pump1 Cooling fan2 Water pump pulley3 Fan belt4 Water bypass hose5 Water pump assembly KEY POINTS FOR REMOVALRemoval of the water pump pulley and fan belt is possible after loosening slightly both the nut (1) on the alternator support bolt and the adjusting bolt (2). This allows the alternator to be moved and then the V-belt slackened.

Removing water pump pulley KEY POINTS FOR INSPECTIONTurn the pump by hand to check the impeller and shaft for smooth and quiet rotation. If irregular or noisy rotation is detected, replace them as an assembly.

Inspecting impeller and shaft rotation2.2 Installation

Correct locations of water pump mounting bolts KEY POINTS FOR INSPECTION(1) Install the six water pump mounting bolts in their correct locations by referring to the figure on the right for the nominal diameters and lengths from bottom of head.(2) Use a new gasket when installing the water pump.(3) Adjust the fan belt tension according to the following specification.

Fan belt tension adjustment

Unit: mm (in.)3. Thermostat

3.1 Disassembly

Removal sequence and points to check on thermostat1 Water outlet fitting2 Thermostat3 Thermostat fitting4 Water joint5 Temperature joint6 Thermounit3.2 Inspection KEY POINTS FOR INSPECTION(1) Operation Test of ThermostatPut the thermostat in a container of water. Heat the water and record both of the temperatures at which the valve starts to open and at which the valve lift reaches 8 mm (0.3 in.). If the readings do not conform to the specification below, replace the thermostat.

Carry out this operation with extreme care to avoid burns and prevent fire.

Operation test of thermostat(2) Thermounit InspectionPlace the temperature sensing section of the thermounit in a container of oil. Heat the oil to a temperature in each of the ranges shown below and measure the resistance between the terminal and body for each of the temperature. If the resistances are largely different from those specified below, replace the thermounit.

Unit: Ohms

Carry out this operation with extreme care to avoid burns and prevent fire.

Thermounit inspection3.3 InstallationExcept that the instructions shown below are to be followed, perform installation by following the removal sequence in reverse. KEY POINTS FOR INSTALLATION(1) Temperature jointApply sealant to the threads and tighten to the specified torque. (2) ThermostatMake sure that the thermostat flange is correctly fit into the counterbore in the intake manifold.

Installing temperature joint

Installing thermostat