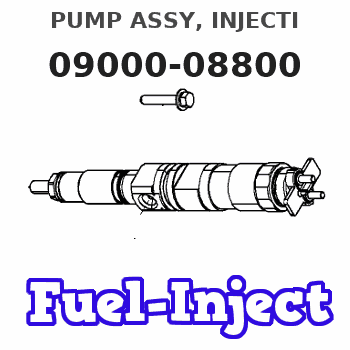

Information pump assy, injecti

Rating:

KIT List:

| Body assy, injecti | 1904400340 |

| Governor assy, mec | 1908900150 |

| Pump assy, fuel fe | 1922900060 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$4,304.22

17 Nov 2022

US: Leksas Shop

MRC (SKF) 5221C - Double Row Angular Contact Bearing - 105 mm Bore, 190 mm OD, 2.5625 in Width, Open, 30 ° Contact Angle, C0

Generic bore diameter: 105 mm || radial static load capacity: 40500 lbf || outside diameter: 190 mm || cage material: Steel || overall width: 2.5625 in

Generic bore diameter: 105 mm || radial static load capacity: 40500 lbf || outside diameter: 190 mm || cage material: Steel || overall width: 2.5625 in

Components :

| 001. | PUMP ASSY, INJECTI | 09000-08800 |

| 002. | BODY ASSY, INJECTI | 09010-02700 |

| 003. | GOVERNOR ASSY, MEC | 09080-01310 |

| 004. | PUMP ASSY, FUEL FE | 09210-00073 |

Scheme ###:

| 000. | [01] | 09000-08800 | PUMP ASSY, INJECTI | 01706830 |

| 004. | [01] | 94918-00310 | SCREW, HOLLOW | 21702980 |

| 008. | [01] | 09080-01310 | GOVERNOR ASSY, MEC | 0908001310 |

| 009. | [01] | 09210-00073 | PUMP ASSY, FUEL FE | 02001312 |

| 010. | [01] | 09010-02700 | BODY ASSY, INJECTI | 0901002700 |

| 011. | [01] | 94905-02450 | NUT, HEXAGON | 21703380 |

| 012. | [01] | 94901-50500 | WASHER, SPRING | 21703370 |

| 013. | [01] | 94913-00190 | KEY, WOODRUFF | |

| 015. | [01] | 09001-80140 | COVER, CONTROL RAC | 21703400 |

| 016. | [01] | 94901-81020 | WASHER, COPPER PLA | 21706370 |

| 017. | [04] | 09022-20011 | WASHER, FUEL PIPE | 21703000 |

| 017. | [04] | 09022-20070 | WASHER, FUEL PIPE | |

| 018. | [01] | 09031-00011 | VALVE ASSY, OVERFL | 21701340 |

| 019. | [01] | 09024-40080 | SCREW, AIR BLEEDER | 21704700 |

| 020. | [06] | 94900-50191 | SCREW, SLOTTED FLA | 9490050190 |

| 021. | [01] | 91518-08221 | BOLT, W/WASHER |

Include in #3:

09000-08800

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09000-08800 | 01706830 | PUMP ASSY, INJECTI | |

| 01706830 | MITSUI DEUTZ | PUMP ASSY, INJECTI |

Information:

Calibration

Refer to the complete Oil and Filter change procedure before performing Calibration (if applicable).Your engine may use a dipstick that has a FULL RANGE zone rather than the traditional FULL mark. The FULL RANGE is between the ADD and FULL marks (X-Y). This dipstick allows for variations in engine installations. Engine oil level will vary, depending on angle (front to back tilt) and slant sideways tilt).To determine the correct FULL mark in the FULL RANGE zone and prevent overfilling or under filling the crankcase, it is important to calibrate (or verify the calibration of) the dipstick at the first oil change.To verify the ADD mark and establish the actual FULL mark in the FULL RANGE zone of the dipstick, use the following procedure. This procedure is correct for use with either the non-spacer plate oil pan or the spacer plate oil pan. Sump capacities and oil levels are the same for each oil pan. The engine must rest on a level surface for this procedure.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

1. Operate the engine until it reaches normal operating temperature.2. Stop the engine. Remove the crankcase drain plug(s). Let the oil drain from the crankcase for 20 minutes.3. Remove the used oil filter(s). Install the new oil filter(s). Install the crankcase drain plug(s) and tighten to 70 14 N m (50 10 lb ft).4. Add 18 L (19 qt) of oil for 3306B engines or 16 L (17 qt) of oil for 3304B engines. Allow the oil to drain back to the sump for a minimum of five minutes.5. Ensure that the oil level gauge is seated. Check the oil level on the oil level gauge. The oil level should be at the ADD mark. If the oil level is not at the existing ADD mark, use an engraving tool to grind off the mark and engrave the new ADD level.6. Add 6 L (6 qt) of oil for 3306B engines or 2.5 L (2.5 qt) of oil for 3304B engines into the sump. Allow enough time for the oil to drain into the sump.7. Ensure that the oil level gauge is seated. Check the oil level on the oil level gauge. The oil level should be at the FULL mark. If the oil level is not at the existing FULL mark, use an engraving tool to grind off the mark and engrave the new FULL level.

Remote mounted or auxiliary oil filters require additional oil. For all information about auxiliary oil filters, refer to the OEM instructions.

8. Add an additional 4 L (4 qt) of oil into the sump for both the 3306B and the 3304B engines. Total fill capacity for the 3306B engine is 27.5 L (29 qt) Total fill capacity for the 3304B engine is 22.5 L (23.5 qt).

To prevent crankshaft or bearing damage, crank the engine with the fuel OFF in order to fill all of the oil filters

Refer to the complete Oil and Filter change procedure before performing Calibration (if applicable).Your engine may use a dipstick that has a FULL RANGE zone rather than the traditional FULL mark. The FULL RANGE is between the ADD and FULL marks (X-Y). This dipstick allows for variations in engine installations. Engine oil level will vary, depending on angle (front to back tilt) and slant sideways tilt).To determine the correct FULL mark in the FULL RANGE zone and prevent overfilling or under filling the crankcase, it is important to calibrate (or verify the calibration of) the dipstick at the first oil change.To verify the ADD mark and establish the actual FULL mark in the FULL RANGE zone of the dipstick, use the following procedure. This procedure is correct for use with either the non-spacer plate oil pan or the spacer plate oil pan. Sump capacities and oil levels are the same for each oil pan. The engine must rest on a level surface for this procedure.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

1. Operate the engine until it reaches normal operating temperature.2. Stop the engine. Remove the crankcase drain plug(s). Let the oil drain from the crankcase for 20 minutes.3. Remove the used oil filter(s). Install the new oil filter(s). Install the crankcase drain plug(s) and tighten to 70 14 N m (50 10 lb ft).4. Add 18 L (19 qt) of oil for 3306B engines or 16 L (17 qt) of oil for 3304B engines. Allow the oil to drain back to the sump for a minimum of five minutes.5. Ensure that the oil level gauge is seated. Check the oil level on the oil level gauge. The oil level should be at the ADD mark. If the oil level is not at the existing ADD mark, use an engraving tool to grind off the mark and engrave the new ADD level.6. Add 6 L (6 qt) of oil for 3306B engines or 2.5 L (2.5 qt) of oil for 3304B engines into the sump. Allow enough time for the oil to drain into the sump.7. Ensure that the oil level gauge is seated. Check the oil level on the oil level gauge. The oil level should be at the FULL mark. If the oil level is not at the existing FULL mark, use an engraving tool to grind off the mark and engrave the new FULL level.

Remote mounted or auxiliary oil filters require additional oil. For all information about auxiliary oil filters, refer to the OEM instructions.

8. Add an additional 4 L (4 qt) of oil into the sump for both the 3306B and the 3304B engines. Total fill capacity for the 3306B engine is 27.5 L (29 qt) Total fill capacity for the 3304B engine is 22.5 L (23.5 qt).

To prevent crankshaft or bearing damage, crank the engine with the fuel OFF in order to fill all of the oil filters