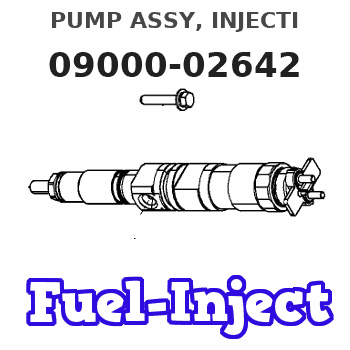

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09000-02642 |

| 002. | BODY ASSY, INJECTI | 09010-00572 |

| 003. | COVER, BEARING | 09020-10053 |

| 004. | TIMER ASSY, AUTOMA | 09180-00270 |

| 005. | PUMP ASSY, FUEL FE | 09210-00342 |

| 006. | COUPLING ASSY | 09240-00043 |

Scheme ###:

| 000. | [01] | 09000-02642 | PUMP ASSY, INJECTI | 6 064 1018 02 |

| 007. | [01] | 09010-00572 | BODY ASSY, INJECTI | 22110-1610 |

| 008. | [01] | 09130-00143 | GOVERNOR ASSY, MEC | 6 075 1301 00 |

| 009. | [06] | 94904-71150 | BOLT, W/WASHER | 6 306 1001 00 |

| 011. | [01] | 91518-08221 | BOLT, W/WASHER | 22815-1190A |

| 013. | [01] | 09001-80090 | COVER, CONTROL RAC | 22114-1250A |

| 014. | [01] | 09180-00270 | TIMER ASSY, AUTOMA | 22510-1290 |

| 015. | [01] | 09001-20010 | NUT, TIMER ROUND | 22353-1050A |

| 016. | [01] | 94913-00050 | KEY, WOODRUFF | 22891-1040A |

| 017. | [01] | 90258-12001 | WASHER, SPRING | 22873-1310A |

| 018. | [01] | 09210-00342 | PUMP ASSY, FUEL FE | 6 065 1501 01 |

| 019. | [01] | 09006-10011 | COVER, PRIMING PUM | 6 053 1552 60 |

| 022. | [01] | 09240-00043 | COUPLING ASSY | 22610-1090A |

| 023. | [01] | 09243-60020 | COUPLING, INJECTIO | 22612-1020A |

Include in #3:

09000-02642

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09000-02642 | 6 064 1018 | PUMP ASSY, INJECTI |

Information:

Specifications

For the oil pump, which is enclosed in the gear case, see Group 1 ENGINE PROPERSpecial Tools

OIL FILTER AND OIL PRESSURE SWITCH

Construction

Oil Filter and Pressure Switch(1) Oil filter(2) Oil pressure switchRemoval and Installation

(1) Coat the O-ring with engine oil. Take care not to twist the O-rings.(2) Coat the threads with sealant (HERMESEAL HI or THREEBOND 1314).(3) Tightening torque: 1.1 - 1.3 kgf m [10.8 - 12.7 N m] (Do not use any wrench.) CAUTION* After installation, check for oil leak while the engine is running.

Installing Oil Filter

Installing Pressure SwitchInspection

Inspect the following:(1) Oil leakPressure switch ON pressure:0.5 0.1 kgf/cm2 [0.05 0.01 MPa] CAUTION* Check the oil filter for dirtiness. If necessary, clean the engine interior with flushing oil.

Inspecting Oil Filter and Switch

For the oil pump, which is enclosed in the gear case, see Group 1 ENGINE PROPERSpecial Tools

OIL FILTER AND OIL PRESSURE SWITCH

Construction

Oil Filter and Pressure Switch(1) Oil filter(2) Oil pressure switchRemoval and Installation

(1) Coat the O-ring with engine oil. Take care not to twist the O-rings.(2) Coat the threads with sealant (HERMESEAL HI or THREEBOND 1314).(3) Tightening torque: 1.1 - 1.3 kgf m [10.8 - 12.7 N m] (Do not use any wrench.) CAUTION* After installation, check for oil leak while the engine is running.

Installing Oil Filter

Installing Pressure SwitchInspection

Inspect the following:(1) Oil leakPressure switch ON pressure:0.5 0.1 kgf/cm2 [0.05 0.01 MPa] CAUTION* Check the oil filter for dirtiness. If necessary, clean the engine interior with flushing oil.

Inspecting Oil Filter and Switch