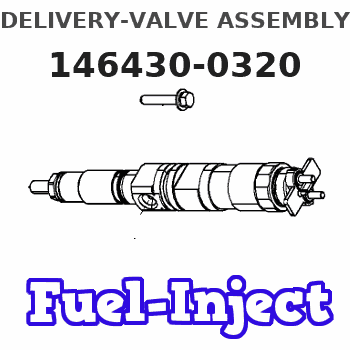

Information delivery-valve assembly

BOSCH

9 413 610 009

9413610009

ZEXEL

146430-0320

1464300320

ISUZU

8944602980

8944602980

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

12pcs/lot Valve 146430-0320, Valve VE4, Diesel Fuel Spare Part, Engine Injection System, for Oil Fuel Engine

Generic

Generic

$25.98

31 Oct 2023

CN: Diesel Injection Par

4Pcs Automotive Delivery Valve 146430-0320 VE4 Injection Pump Delivery Valve 9413610009 8944602980 Fits for Isuzu Elf 4BC2 4JG2

Generic Manufacturer Part Number:146430-0320,9 413 610 009,9413610009,8944602980. || Packing: 4 Pieces Delivery Valve.

Generic Manufacturer Part Number:146430-0320,9 413 610 009,9413610009,8944602980. || Packing: 4 Pieces Delivery Valve.

You can express buy:

USD 14.4

14-06-2025

14-06-2025

12pcs/lot Delivery Valve 146430-0320,9413610009,Delivery Valve VE4, Diesel Fuel Engine Injection System Part,For Oil Fuel Engine

Include in ###:

Number on scheme 55

1047000500

as DELIVERY-VALVE ASSEMBLY

1047000512

as DELIVERY-VALVE ASSEMBLY

VE4

1047000520

as DELIVERY-VALVE ASSEMBLY

1047000523

as DELIVERY-VALVE ASSEMBLY

VE4

1047000530

as DELIVERY-VALVE ASSEMBLY

1047000531

as DELIVERY-VALVE ASSEMBLY

VE4

1047000550

as DELIVERY-VALVE ASSEMBLY

1047003001

as DELIVERY-VALVE ASSEMBLY

VE4

1047003010

as DELIVERY-VALVE ASSEMBLY

1047003040

as DELIVERY-VALVE ASSEMBLY

VE4

1047003050

as DELIVERY-VALVE ASSEMBLY

1047003051

as DELIVERY-VALVE ASSEMBLY

VE4

1047009020

as DELIVERY-VALVE ASSEMBLY

1047009025

as DELIVERY-VALVE ASSEMBLY

VE4

1047009030

as DELIVERY-VALVE ASSEMBLY

1047009033

as DELIVERY-VALVE ASSEMBLY

VE4

1047009041

as DELIVERY-VALVE ASSEMBLY

1047009042

as DELIVERY-VALVE ASSEMBLY

VE4

1047009050

as DELIVERY-VALVE ASSEMBLY

1047009051

as DELIVERY-VALVE ASSEMBLY

VE4

1047009070

as DELIVERY-VALVE ASSEMBLY

1047009071

as DELIVERY-VALVE ASSEMBLY

VE4

1047009080

as DELIVERY-VALVE ASSEMBLY

1047009081

as DELIVERY-VALVE ASSEMBLY

VE4

1047009090

as DELIVERY-VALVE ASSEMBLY

1047009091

as DELIVERY-VALVE ASSEMBLY

VE4

1047009102

as DELIVERY-VALVE ASSEMBLY

1047009110

as DELIVERY-VALVE ASSEMBLY

VE4

1047009140

as DELIVERY-VALVE ASSEMBLY

1047009141

as DELIVERY-VALVE ASSEMBLY

VE4

1047009150

as DELIVERY-VALVE ASSEMBLY

1047009154

as DELIVERY-VALVE ASSEMBLY

VE4

1047009160

as DELIVERY-VALVE ASSEMBLY

1047009162

as DELIVERY-VALVE ASSEMBLY

VE4

1047009170

as DELIVERY-VALVE ASSEMBLY

1047009171

as DELIVERY-VALVE ASSEMBLY

VE4

1047009220

as DELIVERY-VALVE ASSEMBLY

1047009221

as DELIVERY-VALVE ASSEMBLY

VE4

1047011000

as DELIVERY-VALVE ASSEMBLY

1047011004

as DELIVERY-VALVE ASSEMBLY

VE4

1047011020

as DELIVERY-VALVE ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

146430-0320

8944602980 ISUZU

DELIVERY-VALVE ASSEMBLY

C 11FJ DELIVERY VALVE DV(VE) DV

C 11FJ DELIVERY VALVE DV(VE) DV

146430-0320

ME756471 MITSUBISHI

DELIVERY-VALVE ASSEMBLY

C 11FJ DELIVERY VALVE DV(VE) DV

C 11FJ DELIVERY VALVE DV(VE) DV

146430-0320

1677389TA2 NISSAN

DELIVERY-VALVE ASSEMBLY

C 11FJ DELIVERY VALVE DV(VE) DV

C 11FJ DELIVERY VALVE DV(VE) DV

146430-0320

16776R8100 NISSAN-DIESEL

DELIVERY-VALVE ASSEMBLY

C 11FJ DELIVERY VALVE DV(VE) DV

C 11FJ DELIVERY VALVE DV(VE) DV

146430-0320

RF1124140 MAZDA

DELIVERY-VALVE ASSEMBLY

C 11FJ DELIVERY VALVE DV(VE) DV

C 11FJ DELIVERY VALVE DV(VE) DV

146430-0320

16776R8100 MAZDA

DELIVERY-VALVE ASSEMBLY

A C 11FJ DELIVERY VALVE DV(VE) DV

A C 11FJ DELIVERY VALVE DV(VE) DV

Information:

API Degrees - Temperature Correction Chart for Diesel Fuel

Record the corrected API gravity from this chart.Table of Horsepower Correction Factors

Table 2

Corrected API

Gravity at 60° F Precombustion

Chamber Engines Direct Injection Engines (Use the correct full load RPM)

1800 2000 2200 2400 2600 2800 3000 3200

32.0

32.5

33.0

33.5

34.0 .984

.987

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995

34.5

35.0

35.5

36.0

36.5 .997

1.000

1.003

1.005

1.008 .998

1.000

1.003

1.007

1.013 .998

1.000

1.003

1.007

1.010 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012

37.0

37.5

38.0

38.5

39.0 1.011

1.014

1.017

1.020

1.023 1.014

1.018

1.022

1.025

1.029 1.014

1.018

1.022

1.026

1.030 1.014

1.018

1.022

1.026

1.030 1.015

1.019

1.022

1.026

1.030 1.015

1.019

1.023

1.027

1.031 1.016

1.020

1.024

1.028

1.032 1.016

1.020

1.024

1.028

1.033 1.016

1.021

1.025

1.029

1.034

39.5

40.0

40.5

41.0

41.5 1.027

1.030

1.034

1.038

1.043 1.034

1.038

1.043

1.048

1.053 1.034

1.038

1.043

1.048

1.054 1.034

1.039

1.044

1.049

1.055 1.035

1.040

1.045

1.050

1.056 1.036

1.040

1.045

1.051

1.056 1.036

1.041

1.046

1.051

1.057 1.037

1.042

1.047

1.053

1.059 1.039

1.045

1.047

1.057

1.064

42.0

42.5

43.0

43.5

44.0 1.047

1.053

1.060

1.067

1.076 1.059

1.066

1.073

1.082

1.095 1.060

1.067

1.074

1.084

1.096 1.061

1.068

1.076

1.085

1.098 1.062

1.069

1.077

1.086

1.099 1.063

1.070

1.078

1.087

1.100 1.064

1.071

1.079

1.088

1.102 1.066

1.072

1.081

1.091

1.105 1.072

1.080

1.089

1.099

1.115 Use the above chart to find the horsepower correction factor.Calculating the Corrected Horsepower

Determine the rated full load horsepower from the Rack Setting Information Book.

Divide the rated horsepower by the horsepower correction factor for fuel density; the result is the corrected horsepower.Example:1674 - Truck Engine Serial No. 94B2551Rated Horsepower: 270 HorsepowerCalculations:

Table 3

1. Measured API gravity: 40.4' API at 50' (round to 40' API)

2. Corrected API gravity (see chart): 41' API at 60'F

3. Hpr correction factor (see chart): 1.038

4. Corrected Hp = Rated Hpr = 270 = 260 Hp

Correction Factor 1.038 (or 3.75% hp loss) Correcting for Fuel Density When Testing Engines on a Dynamometer

When engines are tested on a dynamometer which measures actual flywheel or drive train output, the observed horsepower is dependent on the fuel used. If the fuel being used is not 35° API at 60°F, then any dynamometer readings must be corrected to determine the output if 35° API fuel had been used. The same horsepower correction factor is used, but the formula is different:Corrected Horsepower = Observed Horsepower x Horsepower Correction FactorExample:1674 Truck Engine, Serial No. 9482551Rated (full load Horsepower: 270 Horsepower)Observed (dynamometer) Horsepower: 260 HorsepowerCalculations:

Measured API gravity: 39.6° API at 50°F (round to 40° API)

Corrected API Gravity (see chart): 41° API at 60°F

Horsepower Correction Factor (see chart): 1.038

Corrected Horsepower = Observed Horsepower x Horsepower Correction Factor 260 horsepower x 1.038 = 270 horsepower(Although the dynamometer indicated low horsepower, if the proper fuel had been used, the engine would be operating at rated output. The factory tolerance on rated engine output is 3%.)REFERENCE: For more information on dynamometer testing diesel engines, see Special Instruction Form GEG01024 .Diesel Fuel API Gravity to IbsJU.S. gallon or kg/liter Conversion Chart

The following chart may be used to convert the fuel API gravity to Ibs./U.S. gallon or kg/liter. These weights are for reference and are to be used when evaluating engine performance. Measurement of fuel flow rates can be converted

Record the corrected API gravity from this chart.Table of Horsepower Correction Factors

Table 2

Corrected API

Gravity at 60° F Precombustion

Chamber Engines Direct Injection Engines (Use the correct full load RPM)

1800 2000 2200 2400 2600 2800 3000 3200

32.0

32.5

33.0

33.5

34.0 .984

.987

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995

34.5

35.0

35.5

36.0

36.5 .997

1.000

1.003

1.005

1.008 .998

1.000

1.003

1.007

1.013 .998

1.000

1.003

1.007

1.010 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012

37.0

37.5

38.0

38.5

39.0 1.011

1.014

1.017

1.020

1.023 1.014

1.018

1.022

1.025

1.029 1.014

1.018

1.022

1.026

1.030 1.014

1.018

1.022

1.026

1.030 1.015

1.019

1.022

1.026

1.030 1.015

1.019

1.023

1.027

1.031 1.016

1.020

1.024

1.028

1.032 1.016

1.020

1.024

1.028

1.033 1.016

1.021

1.025

1.029

1.034

39.5

40.0

40.5

41.0

41.5 1.027

1.030

1.034

1.038

1.043 1.034

1.038

1.043

1.048

1.053 1.034

1.038

1.043

1.048

1.054 1.034

1.039

1.044

1.049

1.055 1.035

1.040

1.045

1.050

1.056 1.036

1.040

1.045

1.051

1.056 1.036

1.041

1.046

1.051

1.057 1.037

1.042

1.047

1.053

1.059 1.039

1.045

1.047

1.057

1.064

42.0

42.5

43.0

43.5

44.0 1.047

1.053

1.060

1.067

1.076 1.059

1.066

1.073

1.082

1.095 1.060

1.067

1.074

1.084

1.096 1.061

1.068

1.076

1.085

1.098 1.062

1.069

1.077

1.086

1.099 1.063

1.070

1.078

1.087

1.100 1.064

1.071

1.079

1.088

1.102 1.066

1.072

1.081

1.091

1.105 1.072

1.080

1.089

1.099

1.115 Use the above chart to find the horsepower correction factor.Calculating the Corrected Horsepower

Determine the rated full load horsepower from the Rack Setting Information Book.

Divide the rated horsepower by the horsepower correction factor for fuel density; the result is the corrected horsepower.Example:1674 - Truck Engine Serial No. 94B2551Rated Horsepower: 270 HorsepowerCalculations:

Table 3

1. Measured API gravity: 40.4' API at 50' (round to 40' API)

2. Corrected API gravity (see chart): 41' API at 60'F

3. Hpr correction factor (see chart): 1.038

4. Corrected Hp = Rated Hpr = 270 = 260 Hp

Correction Factor 1.038 (or 3.75% hp loss) Correcting for Fuel Density When Testing Engines on a Dynamometer

When engines are tested on a dynamometer which measures actual flywheel or drive train output, the observed horsepower is dependent on the fuel used. If the fuel being used is not 35° API at 60°F, then any dynamometer readings must be corrected to determine the output if 35° API fuel had been used. The same horsepower correction factor is used, but the formula is different:Corrected Horsepower = Observed Horsepower x Horsepower Correction FactorExample:1674 Truck Engine, Serial No. 9482551Rated (full load Horsepower: 270 Horsepower)Observed (dynamometer) Horsepower: 260 HorsepowerCalculations:

Measured API gravity: 39.6° API at 50°F (round to 40° API)

Corrected API Gravity (see chart): 41° API at 60°F

Horsepower Correction Factor (see chart): 1.038

Corrected Horsepower = Observed Horsepower x Horsepower Correction Factor 260 horsepower x 1.038 = 270 horsepower(Although the dynamometer indicated low horsepower, if the proper fuel had been used, the engine would be operating at rated output. The factory tolerance on rated engine output is 3%.)REFERENCE: For more information on dynamometer testing diesel engines, see Special Instruction Form GEG01024 .Diesel Fuel API Gravity to IbsJU.S. gallon or kg/liter Conversion Chart

The following chart may be used to convert the fuel API gravity to Ibs./U.S. gallon or kg/liter. These weights are for reference and are to be used when evaluating engine performance. Measurement of fuel flow rates can be converted