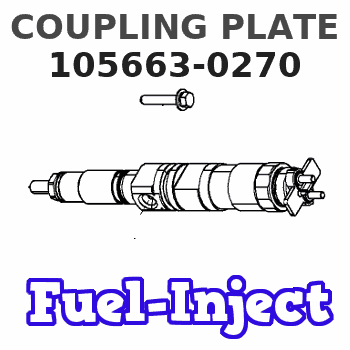

Information coupling plate

BOSCH

9 423 618 362

9423618362

ZEXEL

105663-0270

1056630270

Rating:

Scheme ###:

| 1. | [1] | 156630-6400 | COUPLING PLATE |

| 2. | [2] | 156633-0200 | BLEEDER SCREW |

| 3. | [2] | 156615-3200 | PLAIN WASHER |

| 4. | [1] | 156605-1820 | PLATE |

| 5. | [2] | 014111-0440 | LOCKING WASHER |

| 6. | [2] | 156617-2100 | UNION NUT |

| 7. | [2] | 156633-3300 | BLEEDER SCREW |

| 8. | [2] | 014111-0440 | LOCKING WASHER |

| 9. | [2] | 156622-2500 | BUSHING |

| 10. | [2] | 156615-1500 | PLAIN WASHER |

| 11. | [1] | 156609-4700 | COUPLING |

| 12. | [2] | 156633-3300 | BLEEDER SCREW |

| 13. | [2] | 014111-0440 | LOCKING WASHER |

| 14. | [2] | 156622-2500 | BUSHING |

| 15. | [2] | 156615-1500 | PLAIN WASHER |

| 16. | [1] | 156605-1820 | PLATE |

| 17. | [2] | 156633-0300 | BLEEDER SCREW |

| 18. | [2] | 014111-0440 | LOCKING WASHER |

| 20. | [1] | 156603-7200 | BLEEDER SCREW |

| 21. | [1] | 014111-2440 | LOCKING WASHER D21.5&12.2T3 |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105663-0270

9 423 618 362

COUPLING PLATE

K 14GT COUPLING COUP

K 14GT COUPLING COUP

Information:

Crankcase Breather

Clean

1. Loosen hose clamp (1) and remove the hose from the cover.2. Loosen three breather cover bolts (2) and remove cover (3). 3. Remove breather element (4), and wash in clean, nonflammable solvent and allow to dry. 4. Install clean, dry breather element (4).5. Install cover (3) and bolts (2).5. Install hose and clamp (1). Tighten clamp (1), refer to topic "Torque Specifications" for the proper torque of hose clamp-worm drive band type. If the crankcase breather is not maintained on a regular basis, it will become plugged. A plugged crankcase breather would result in excessive crankcase pressure that may cause crankshaft seal leakage.Alternator, Fan and Accessory Drive Belts

Inspect/Replace

Inspect the condition and adjustment of alternator belts and fan drive belts.Inspect the drive belts for wear and replace if they show any signs of wear. If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Belt Adjustment

* To check the belt tension, apply 25 lbs (110 N) of force midway between the pulleys. Correctly adjusted belts will deflect 1/2 to 3/4 inch (13 to 19 mm).If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys. If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.The engine is equipped with an automatic belt tensioner, adjustments should not be necessary.Hoses and Clamps

Inspect/Replace

Hose replacement prior to failure is a cost effective preventive maintenance practice. Replacing a hose before it fails saves money and reduces the chances for unscheduled downtime. By replacing a hose that is cracked, soft or leaking, you will avoid major repairs that could result in a severe engine overheating problem. * Inspect all hoses for leaks due to cracking, softness and loose clamps.* Replace hoses that are cracked or soft and tighten loose clamps.Before Replacing Hoses

1. After engine is cool, loosen the radiator filler cap slowly to relieve any pressure and remove the cap.2. Drain the coolant from the cooling system to a level below the hose being replaced.3. Remove the hose clamps, disconnect the old hose and replace with a new hose.4. Install hose clamps. (See the Torque for Standard Hose Clamps-Worm Band Type chart in the Torque Specifications section of this publication for the appropriate torque.) For constant torque hose clamps, see the Torque Specifications section in this publication.After Replacing Hoses

Refer to the Cooling System Specifications and Cooling System-Test for Coolant Additive maintenance topics in this publication.5. Add coolant mixture to the cooling system. Bring it to the proper level by mixing a solution of acceptable water and Caterpillar Antifreeze. Test for supplemental additive (Conditioner) concentration. Add proper amount, or if equipped with a coolant additive element, install the appropriate element

Clean

1. Loosen hose clamp (1) and remove the hose from the cover.2. Loosen three breather cover bolts (2) and remove cover (3). 3. Remove breather element (4), and wash in clean, nonflammable solvent and allow to dry. 4. Install clean, dry breather element (4).5. Install cover (3) and bolts (2).5. Install hose and clamp (1). Tighten clamp (1), refer to topic "Torque Specifications" for the proper torque of hose clamp-worm drive band type. If the crankcase breather is not maintained on a regular basis, it will become plugged. A plugged crankcase breather would result in excessive crankcase pressure that may cause crankshaft seal leakage.Alternator, Fan and Accessory Drive Belts

Inspect/Replace

Inspect the condition and adjustment of alternator belts and fan drive belts.Inspect the drive belts for wear and replace if they show any signs of wear. If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Belt Adjustment

* To check the belt tension, apply 25 lbs (110 N) of force midway between the pulleys. Correctly adjusted belts will deflect 1/2 to 3/4 inch (13 to 19 mm).If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys. If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.The engine is equipped with an automatic belt tensioner, adjustments should not be necessary.Hoses and Clamps

Inspect/Replace

Hose replacement prior to failure is a cost effective preventive maintenance practice. Replacing a hose before it fails saves money and reduces the chances for unscheduled downtime. By replacing a hose that is cracked, soft or leaking, you will avoid major repairs that could result in a severe engine overheating problem. * Inspect all hoses for leaks due to cracking, softness and loose clamps.* Replace hoses that are cracked or soft and tighten loose clamps.Before Replacing Hoses

1. After engine is cool, loosen the radiator filler cap slowly to relieve any pressure and remove the cap.2. Drain the coolant from the cooling system to a level below the hose being replaced.3. Remove the hose clamps, disconnect the old hose and replace with a new hose.4. Install hose clamps. (See the Torque for Standard Hose Clamps-Worm Band Type chart in the Torque Specifications section of this publication for the appropriate torque.) For constant torque hose clamps, see the Torque Specifications section in this publication.After Replacing Hoses

Refer to the Cooling System Specifications and Cooling System-Test for Coolant Additive maintenance topics in this publication.5. Add coolant mixture to the cooling system. Bring it to the proper level by mixing a solution of acceptable water and Caterpillar Antifreeze. Test for supplemental additive (Conditioner) concentration. Add proper amount, or if equipped with a coolant additive element, install the appropriate element

Have questions with 105663-0270?

Group cross 105663-0270 ZEXEL

Mitsubishi

Isuzu

Mitsubishi

Mitsubishi-Heav

Yanmar

Kubota

Isuzu

Mitsubishi

105663-0270

9 423 618 362

COUPLING PLATE