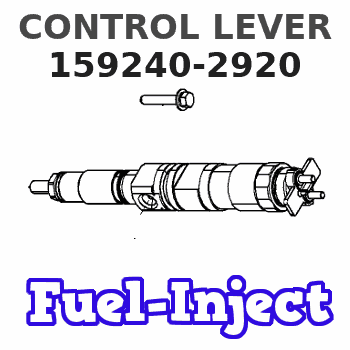

Information control lever

BOSCH

9 421 622 592

9421622592

ZEXEL

159240-2920

1592402920

NISSAN-DIESEL

19268Z9010

19268z9010

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

159240-2920

9 421 622 592

19268Z9010 NISSAN-DIESEL

CONTROL LEVER

C 14GJ LEVER GOV

C 14GJ LEVER GOV

Information:

The results of the preceding procedure are in the following list:

The output corresponds to the desired pressure range. Stop.

The output does not correspond to the desired pressure range. Proceed to 3.

Calibrate the transducer. This assumes that the transducer is mounted on the engine.

Turn the isolation valve on the transducer mounting. This isolates the transducer from the engine. An arrow on the valve indicates the direction of flow. See illustration 2.

Apply a pressure that is equal to 4 mA to the transducer. See table 1. See the pressure port connection in illustration 2.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 4mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 20mA to the transducer. See table 1. See the pressure port connection in illustration 2.Note: The full range of pressure may not be available. Use partial pressure. Use the highest possible pressure. This will yield the best accuracy. See table 1.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 20mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 4mA to the transducer. Verify that the ammeter displays 4mA.The results of the preceding procedure are in the following list:

The output corresponds to the desired pressure range. The transducer is calibrated. Stop.

The output does not correspond to the desired pressure range. Proceed to 4.

Reapply the pressure.

Apply the pressure that is equal to 4mA to the transducer. See table 1. See the pressure port connection in illustration 2.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 4mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 20mA to the transducer. See table 1. See the pressure port connection in illustration 2.Note: The full range of pressure may not be available. Use partial pressure. Use the highest possible pressure. This will yield the best accuracy. See table 1.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 20mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 4mA to the transducer. Verify that the ammeter displays 4mA.The results of the preceding procedure are in the following list:Note: Repeat the procedure several times in order to properly calibrate the transducer. Continue until the 4mA signal is correct and the 20mA signal is correct.

The output corresponds to the desired pressure range. The transducer is calibrated. Stop.

The output does not correspond to the desired pressure range. Replace the transducer. Verify that the repair resolves the problem. Stop.

The output corresponds to the desired pressure range. Stop.

The output does not correspond to the desired pressure range. Proceed to 3.

Calibrate the transducer. This assumes that the transducer is mounted on the engine.

Turn the isolation valve on the transducer mounting. This isolates the transducer from the engine. An arrow on the valve indicates the direction of flow. See illustration 2.

Apply a pressure that is equal to 4 mA to the transducer. See table 1. See the pressure port connection in illustration 2.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 4mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 20mA to the transducer. See table 1. See the pressure port connection in illustration 2.Note: The full range of pressure may not be available. Use partial pressure. Use the highest possible pressure. This will yield the best accuracy. See table 1.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 20mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 4mA to the transducer. Verify that the ammeter displays 4mA.The results of the preceding procedure are in the following list:

The output corresponds to the desired pressure range. The transducer is calibrated. Stop.

The output does not correspond to the desired pressure range. Proceed to 4.

Reapply the pressure.

Apply the pressure that is equal to 4mA to the transducer. See table 1. See the pressure port connection in illustration 2.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 4mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 20mA to the transducer. See table 1. See the pressure port connection in illustration 2.Note: The full range of pressure may not be available. Use partial pressure. Use the highest possible pressure. This will yield the best accuracy. See table 1.

Monitor the ammeter. Adjust the zero dial until the ammeter reads 20mA. See the location of the zero dial that is in illustration 1.

Apply the pressure that is equal to 4mA to the transducer. Verify that the ammeter displays 4mA.The results of the preceding procedure are in the following list:Note: Repeat the procedure several times in order to properly calibrate the transducer. Continue until the 4mA signal is correct and the 20mA signal is correct.

The output corresponds to the desired pressure range. The transducer is calibrated. Stop.

The output does not correspond to the desired pressure range. Replace the transducer. Verify that the repair resolves the problem. Stop.

Have questions with 159240-2920?

Group cross 159240-2920 ZEXEL

Nissan-Diesel

159240-2920

9 421 622 592

19268Z9010

CONTROL LEVER