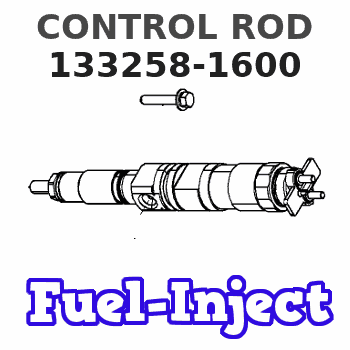

Information control rod

BOSCH

9 411 613 267

9411613267

ZEXEL

133258-1600

1332581600

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$889.49

04 Jun 2019

Parts Expr: Parts Express

RACK - CONTROL FOR MITSUBISHI: 1332581600

MITSUBISHI || All Brand new & rebuilt items comes with 1 year warranty. || RACK - CONTROL FOR MITSUBISHI: Â FORKLIFT. MB1332581600 MB1332581600 MITSUBISHI 1332581600 MB 1332581600 1332581600 MITSUBISHI1332581600 Â Â Â Â Â Â THIS PART IS ALSO LISTED UNDER THE FOLLOWING PART NUMBERS:

MITSUBISHI || All Brand new & rebuilt items comes with 1 year warranty. || RACK - CONTROL FOR MITSUBISHI: Â FORKLIFT. MB1332581600 MB1332581600 MITSUBISHI 1332581600 MB 1332581600 1332581600 MITSUBISHI1332581600 Â Â Â Â Â Â THIS PART IS ALSO LISTED UNDER THE FOLLOWING PART NUMBERS:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

133258-1600

9 411 613 267

CONTROL ROD

C 14FN CONTROL RACK parts(B,Z) Others

C 14FN CONTROL RACK parts(B,Z) Others

Information:

(a)When regrinding journals of the crankshaft, be sure to refinish all journals to the same dimension.(b)Finish the fillet radius to R3 mm [0.1181 in.].

Crankshaft fillet finishing dimension (2)Inspection of Oil Seal Contact Surface

Check the oil seal contact surface of the crankshaft back-end, and, if the crankshaft face has been excessively worn by the oil seal, replace the oil seal and oil sleeve with replacement parts.

Inspection of oil seal contact surface(1) Installation of oil seal sleeveTo install the oil seal sleeve, coat the inner surface of the sleeve with oil, and use the crankshaft sleeve installer for driving the sleeve into place.

Be careful not to dent or scratch the outer surface of the oil seal sleeve.

Inspection of oil seal sleeveWhen the oil seal slinger becomes worn after engine operation, remove the oil seal sleeve by following the procedure below, and replace it with a replacement oil seal assembly (oil seal and oil seal sleeve).

Inspection of oil seal contact surface(2) Removal of oil seal sleeveAt three locations on the sleeve end face, hold a chisel at a right angle to the sleeve and strike with a hammer, and remove the sleeve when it becomes loose.If this method does not allow the removal of the sleeve, hold the chisel in the axial direction and lightly tap to expand and loosen the sleeve.

Be careful not to damage the crankshaft with the chisel when removing the oil seal sleeve.

Removal of oil seal sleeveMeasurement of Crankshaft Deflection

Support the crankshaft on its front and rear journals in V-blocks, and measure the runout at the center journal with a dial gage. Compare the amount of runout with the standard. If the runout is small, correct by grinding. If the runout is large, straighten with a press.If the runout exceeds the limit significantly, replace the crankshaft.

Measurement of crankshaft deflectionRemoval of Crankshaft Gear

Use the gear puller to remove the crankshaft gear. Do not remove the crankshaft gear unless the crankshaft or gear is replaced.

Removal of crankshaft gearInstallation of Crankshaft Gear

(1) Heat the gear to a temperature of 100 to 150 °C [212 to 302 °F].(2) Install the key to the crankshaft.(3) Align the gear with key and insert the gear fully.

Installation of crankshaft gearMeasurement of Cylinder Bore

(1) Using a cylinder gage, measure the cylinder bore and cylindricity. If the limit value is exceeded even at one place, bore all cylinders and replace the pistons and piston rings with oversize pistons and piston rings. Measure at three locations each in directions A and B shown in the diagram.

Measurement of inside diameter of cylinder(2) Boring of cylinders(a) Since there are two piston oversizes (0.25 mm [0.0098 in.] and 0.50 mm [0.0197 in.] oversize) as indicated above, determine the appropriate piston size to be used based on the largest cylinder bore diameter.(b) Measure the outside diameter of the piston to be used. The piston diameter measuring points are shown in the diagram.(c) Based on the measurements of the piston outside diameter, calculate the finishing dimension to be achieved by boring.A: Piston

Have questions with 133258-1600?

Group cross 133258-1600 ZEXEL

133258-1600

9 411 613 267

CONTROL ROD