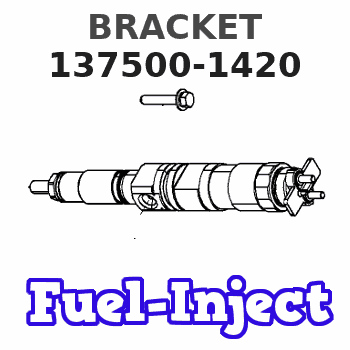

Information bracket

BOSCH

9 411 614 286

9411614286

ZEXEL

137500-1420

1375001420

KOMATSU

6354713100

6354713100

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

137500-1420

9 411 614 286

6354713100 KOMATSU

BRACKET

C 14FL BRACKET parts(A,AD) Others

C 14FL BRACKET parts(A,AD) Others

Information:

Performance Analysis Report (PAR) Chassis Dynamometer Test

Required Equipment For Test:

Optional Equipment:

Refer to the latest PAR instructions, Special Instruction Form No. SEHS8025, for more detailed instructions concerning preparation of the truck, proper use of the dynamometer and use of the Technical Information File microfiche.Use the following procedure for the PAR Chassis Dynamomenter test:1. Check the fuel API if not done in another procedure. Refer to, Special Instruction, Form No. GMGO0977.2. Record data from the Engine Information Plate.3. Install the required measurement instruments on the engine.4. Operate the engine at partial throttle and load to obtain the normal operating temperature, and then operate the engine at full load for two minutes. While operating at full load, check the fuel pressure [approximately 550 kPa (80 psi)]. If the pressure is low, perform Procedure No. 113T (part of Truck Performance Diagnostic Guide, Form No. SEBD0808), before continuing the test.5. Beginning from Top Engine Limit, load the engine to each test rpm, 5 rpm, for at least two minutes for proper stabilization.6. Record engine test information, in sequence if possible, on the record sheets. If repeat runs are required to complete the sheets, be sure temperatures and conditions are as equal as possible.7.

Required Equipment For Test:

Optional Equipment:

Refer to the latest PAR instructions, Special Instruction Form No. SEHS8025, for more detailed instructions concerning preparation of the truck, proper use of the dynamometer and use of the Technical Information File microfiche.Use the following procedure for the PAR Chassis Dynamomenter test:1. Check the fuel API if not done in another procedure. Refer to, Special Instruction, Form No. GMGO0977.2. Record data from the Engine Information Plate.3. Install the required measurement instruments on the engine.4. Operate the engine at partial throttle and load to obtain the normal operating temperature, and then operate the engine at full load for two minutes. While operating at full load, check the fuel pressure [approximately 550 kPa (80 psi)]. If the pressure is low, perform Procedure No. 113T (part of Truck Performance Diagnostic Guide, Form No. SEBD0808), before continuing the test.5. Beginning from Top Engine Limit, load the engine to each test rpm, 5 rpm, for at least two minutes for proper stabilization.6. Record engine test information, in sequence if possible, on the record sheets. If repeat runs are required to complete the sheets, be sure temperatures and conditions are as equal as possible.7.