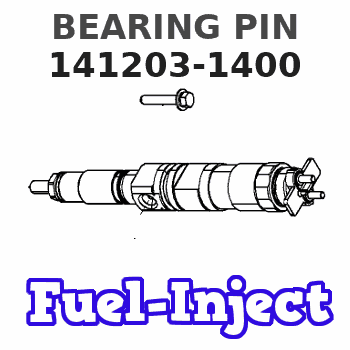

Information bearing pin

BOSCH

9 411 619 736

9411619736

ZEXEL

141203-1400

1412031400

NKK

217290

217290

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$176.77

25 Aug 2024

0.13[0.06] Pounds

US: Mara Industrial

Ohmart 217290 KYBD./DSPY.Controller Bd 217291

Ohmart

Ohmart

Cross reference number

Zexel num

Bosch num

Firm num

Name

141203-1400

9 411 619 736

217290 NKK

BEARING PIN

C

C

Information:

Location of Components

Illustration 1 g06494607

Typical example

(A) DEF tank breather

(B) Heater relay

(C) DEF fast fill tank-mounted valve

(D) Plug heater

(E) Heated supply line

(F) DEF fast fill receiver

(G) DEF tank

Illustration 2 g06494608

(C) DEF fast fill tank-mounted valveThe ground level DEF fill system works much like the ground level fast fuel system. DEF fast fill tank-mounted valve (C) is mounted in DEF tank (G). Fast fill tank-mounted valve (C) has a piston that is normally closed with a spring.

Illustration 3 g06516649

(H) O-Ring seal

(J) Flow In

(K) Flow Out

(L) Back cavityNote: O-Ring seal (H) allows small amount of fluid flow.Note: The main flow through the valve is not shown.Note: During normal flow conditions there is no pressure built up in back cavity (L). Back cavity (L) is essentially "open to atmosphere".When filling, the DEF flow opens the piston, past the diverter shield and a portion flows through an orifice in the piston into the float area.

Illustration 4 g06516652

(L) Back cavity

(M) Rolling diaphragm

(N) O-Ring seal

(P) Drain holeNote: O-Ring seal (N) prevents any flow from back cavity (L).Note: Once the float rises, the pressure in back cavity (L) equals the pressure pushing the front of rolling diaphragm (M). Since the area behind rolling diaphragm (M) is greater than the area in front, along with the spring force, diaphragm (M) is held shut.When the tank level causes the float to rise high enough, the orifice is blocked, causing increased pressure on the piston until valve (C) closes. The increased pressure in the fill line then causes the nozzle attached to the receiver to shut off.The nozzle shuts off when the nozzle sees 172 to 200 kPa (25 to 29 psi) resistance. If pressure is not great enough from the source pump/supply at nozzle, there is not enough pressure built up in line between valve and nozzle to trigger nozzle shut off and DEF exits the breather-overfill.Targeted flow for the DEF supply pump should be 45 L/min (12 US gpm). Excessive flow can lead to premature shut-off of DEF nozzle.DEF tank valve (C), supply line (E), and DEF fast fill receiver (F) are electrically heated based on ambient temperature, battery, and alternator loads controlled through heater relay (B). For heated DEF hose repair kit, refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines".Note: If receiver (F) and supply line (E) on machine are drained for storage, the system must be refilled via the ground fill connection. The system is refilled to ensure that plug heater (D) in receiver (F) remains submerged in DEF fluid during the heating operation.

Plug heater (D) probe must be submerged at least 80% in DEF fluid to prevent overheating that could lead to plug heater (D) failing.

Illustration 1 g06494607

Typical example

(A) DEF tank breather

(B) Heater relay

(C) DEF fast fill tank-mounted valve

(D) Plug heater

(E) Heated supply line

(F) DEF fast fill receiver

(G) DEF tank

Illustration 2 g06494608

(C) DEF fast fill tank-mounted valveThe ground level DEF fill system works much like the ground level fast fuel system. DEF fast fill tank-mounted valve (C) is mounted in DEF tank (G). Fast fill tank-mounted valve (C) has a piston that is normally closed with a spring.

Illustration 3 g06516649

(H) O-Ring seal

(J) Flow In

(K) Flow Out

(L) Back cavityNote: O-Ring seal (H) allows small amount of fluid flow.Note: The main flow through the valve is not shown.Note: During normal flow conditions there is no pressure built up in back cavity (L). Back cavity (L) is essentially "open to atmosphere".When filling, the DEF flow opens the piston, past the diverter shield and a portion flows through an orifice in the piston into the float area.

Illustration 4 g06516652

(L) Back cavity

(M) Rolling diaphragm

(N) O-Ring seal

(P) Drain holeNote: O-Ring seal (N) prevents any flow from back cavity (L).Note: Once the float rises, the pressure in back cavity (L) equals the pressure pushing the front of rolling diaphragm (M). Since the area behind rolling diaphragm (M) is greater than the area in front, along with the spring force, diaphragm (M) is held shut.When the tank level causes the float to rise high enough, the orifice is blocked, causing increased pressure on the piston until valve (C) closes. The increased pressure in the fill line then causes the nozzle attached to the receiver to shut off.The nozzle shuts off when the nozzle sees 172 to 200 kPa (25 to 29 psi) resistance. If pressure is not great enough from the source pump/supply at nozzle, there is not enough pressure built up in line between valve and nozzle to trigger nozzle shut off and DEF exits the breather-overfill.Targeted flow for the DEF supply pump should be 45 L/min (12 US gpm). Excessive flow can lead to premature shut-off of DEF nozzle.DEF tank valve (C), supply line (E), and DEF fast fill receiver (F) are electrically heated based on ambient temperature, battery, and alternator loads controlled through heater relay (B). For heated DEF hose repair kit, refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines".Note: If receiver (F) and supply line (E) on machine are drained for storage, the system must be refilled via the ground fill connection. The system is refilled to ensure that plug heater (D) in receiver (F) remains submerged in DEF fluid during the heating operation.

Plug heater (D) probe must be submerged at least 80% in DEF fluid to prevent overheating that could lead to plug heater (D) failing.

Have questions with 141203-1400?

Group cross 141203-1400 ZEXEL

Nkk

141203-1400

9 411 619 736

217290

BEARING PIN