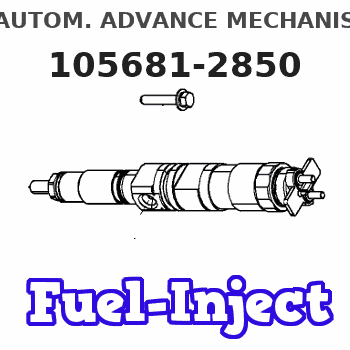

Information autom. advance mechanism

BOSCH

9 420 617 054

9420617054

ZEXEL

105681-2850

1056812850

Rating:

Scheme ###:

| 1. | [1] | 156800-2620 | TIMING-DEVICE HOUSING |

| 2. | [1] | 156801-3300 | FLANGE BUSHING |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 5. | [1] | 156898-8720 | FLYWEIGHT ASSEMBLY |

| 5/1. | [2] | 156802-5020 | FLYWEIGHT |

| 5/1. | [2] | 156802-5020 | FLYWEIGHT |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/4. | [4] | 156893-0100 | COMPRESSION SPRING |

| 5/4. | [4] | 156893-0100 | COMPRESSION SPRING |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/7. | [2] | 156806-0900 | PIN |

| 5/8/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 5/8/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 5/8/1. | [0] | 156728-0900 | SHIM D19&15T0.3 |

| 5/8/1. | [0] | 156728-1000 | SHIM D19&15T0.5 |

| 5/8/1. | [0] | 156728-1100 | SHIM D19&15T1.0 |

| 5/8/1. | [0] | 156728-2000 | SHIM D19&15T0.4 |

| 5/8/1. | [0] | 156728-2100 | SHIM D19&15T0.7 |

| 5/8/1. | [0] | 156728-2400 | SHIM D19&15T0.6 |

| 5/8/1. | [0] | 156728-2500 | SHIM D19&15T0.8 |

| 5/8/1. | [0] | 156728-2600 | SHIM D19&15T0.9 |

| 5/10. | [2] | 156808-0800 | SPACER BUSHING |

| 13. | [1] | 156809-3220 | COVER |

| 13/2. | [1] | 139648-0600 | PACKING RING |

| 13/3. | [1] | 156315-0300 | O-RING |

| 15. | [4] | 156897-7500 | COMPRESSION SPRING |

| 15. | [4] | 156897-7500 | COMPRESSION SPRING |

| 15B. | [4] | 156897-8000 | COMPRESSION SPRING |

| 15B. | [4] | 156897-8000 | COMPRESSION SPRING |

| 21. | [4] | 156809-0300 | LOCKING WASHER |

| 21. | [4] | 156809-0300 | LOCKING WASHER |

| 24/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 24/1. | [0] | 156728-0900 | SHIM D19&15T0.3 |

| 24/1. | [0] | 156728-1000 | SHIM D19&15T0.5 |

| 24/1. | [0] | 156728-1100 | SHIM D19&15T1.0 |

| 24/1. | [0] | 156728-2000 | SHIM D19&15T0.4 |

| 24/1. | [0] | 156728-2100 | SHIM D19&15T0.7 |

| 24/1. | [0] | 156728-2400 | SHIM D19&15T0.6 |

| 24/1. | [0] | 156728-2400 | SHIM D19&15T0.6 |

| 24/1. | [0] | 156728-2500 | SHIM D19&15T0.8 |

| 24/1. | [0] | 156728-2600 | SHIM D19&15T0.9 |

| 30. | [1] | 156322-0000 | LOCKING WASHER |

| 31. | [1] | 134325-0800 | UNION NUT |

| 33. | [1] | 029331-0190 | GASKET D14&10.2T1 |

| 34. | [1] | 156316-0000 | CAPSULE |

| 35. | [1] | 156314-0600 | CAP |

| 36. | [1] | 156319-0200 | GASKET |

Include in #1:

106671-6760

as AUTOM. ADVANCE MECHANIS

Cross reference number

Zexel num

Bosch num

Firm num

Name

105681-2850

AUTOM. ADVANCE MECHANISM

K 14KL AUTOMATIC TIMER TIMER SPG TIMER

K 14KL AUTOMATIC TIMER TIMER SPG TIMER

Information:

Introduction

Procedure to prevent injector Plunger Spring failure due to inadequate fuel system priming.

The low-pressure fuel system must be primed after injector replacement or other repair to the low-pressure fuel system circuit which may allow air to enter the system.

Inadequate priming can result in air being present in the low-pressure fuel system and inside the injectors.

Attempting to start the engine without adequate priming may result in an early hour failure of the injector plunger spring.

Follow the procedure below to prevent injector failure due to inadequate priming.

DO NOT START THE ENGINE WITHOUT PRIMING THE FUEL SYSTEM

Illustration 1 g03735591

Damaged plunger spring due to improper fuel system primingFuel System Priming Procedure:

Disconnect the injector harness at the valve cover.

Use the hand primer to fill the fuel system. Pump until the hand primer becomes too hard to depress by hand.

Crank the engine 3 times for 15 seconds each. Reapply the hand primer after each cranking cycle.

Once the hand primer remains hard to depress after the 15 second crank, reconnect the injector harness and start the engine.

Clear any related fault codes (ET) that were logged while cranking the engine with the injector harness disconnected.

Illustration 2 g03736011

Procedure to prevent injector Plunger Spring failure due to inadequate fuel system priming.

The low-pressure fuel system must be primed after injector replacement or other repair to the low-pressure fuel system circuit which may allow air to enter the system.

Inadequate priming can result in air being present in the low-pressure fuel system and inside the injectors.

Attempting to start the engine without adequate priming may result in an early hour failure of the injector plunger spring.

Follow the procedure below to prevent injector failure due to inadequate priming.

DO NOT START THE ENGINE WITHOUT PRIMING THE FUEL SYSTEM

Illustration 1 g03735591

Damaged plunger spring due to improper fuel system primingFuel System Priming Procedure:

Disconnect the injector harness at the valve cover.

Use the hand primer to fill the fuel system. Pump until the hand primer becomes too hard to depress by hand.

Crank the engine 3 times for 15 seconds each. Reapply the hand primer after each cranking cycle.

Once the hand primer remains hard to depress after the 15 second crank, reconnect the injector harness and start the engine.

Clear any related fault codes (ET) that were logged while cranking the engine with the injector harness disconnected.

Illustration 2 g03736011