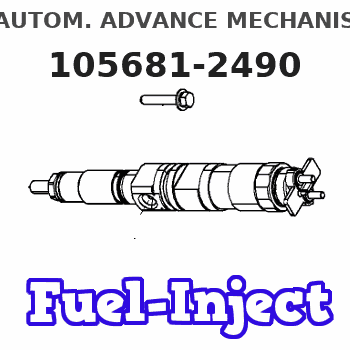

Information autom. advance mechanism

BOSCH

9 420 615 858

9420615858

ZEXEL

105681-2490

1056812490

MITSUBISHI

ME748077

me748077

Rating:

Scheme ###:

| 1. | [1] | 156800-2620 | TIMING-DEVICE HOUSING |

| 2. | [1] | 156801-1700 | FLANGE BUSHING |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 5. | [1] | 156819-6620 | FLYWEIGHT ASSEMBLY |

| 5/1. | [2] | 156802-6820 | FLYWEIGHT |

| 5/1. | [2] | 156802-6820 | FLYWEIGHT |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/4. | [4] | 156895-2300 | COMPRESSION SPRING |

| 5/4. | [4] | 156895-2300 | COMPRESSION SPRING |

| 5/5. | [4] | 156895-2400 | COMPRESSION SPRING |

| 5/5. | [4] | 156895-2400 | COMPRESSION SPRING |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/7. | [2] | 156806-0900 | PIN |

| 5/8/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 5/8/1. | [0] | 156728-0900 | SHIM D19&15T0.3 |

| 5/8/1. | [0] | 156728-1000 | SHIM D19&15T0.5 |

| 5/8/1. | [0] | 156728-1100 | SHIM D19&15T1.0 |

| 5/8/1. | [0] | 156728-2000 | SHIM D19&15T0.4 |

| 5/8/1. | [0] | 156728-2000 | SHIM D19&15T0.4 |

| 5/8/1. | [0] | 156728-2100 | SHIM D19&15T0.7 |

| 5/9/1. | [0] | 156728-1200 | SHIM D14&10.6T0.1 |

| 5/9/1. | [0] | 156728-1300 | SHIM D14&10.6T0.3 |

| 5/9/1. | [0] | 156728-1400 | SHIM D14&10.6T0.5 |

| 5/9/1. | [0] | 156728-1500 | SHIM D14&10.6T1.0 |

| 5/9/1. | [0] | 156728-2200 | SHIM D14&10.6T0.4 |

| 5/9/1. | [0] | 156728-2200 | SHIM D14&10.6T0.4 |

| 5/9/1. | [0] | 156728-2300 | SHIM D14&10.6T0.7 |

| 5/10. | [2] | 156808-0800 | SPACER BUSHING |

| 13. | [1] | 156809-1620 | COVER |

| 13/2. | [1] | 139648-0300 | PACKING RING |

| 13/3. | [1] | 156315-0200 | O-RING |

| 30. | [1] | 156322-0000 | LOCKING WASHER |

| 31. | [1] | 134325-0800 | UNION NUT |

| 33. | [1] | 029331-0190 | GASKET D14&10.2T1 |

| 34. | [1] | 156316-0000 | CAPSULE |

| 35. | [1] | 156314-0600 | CAP |

| 36. | [1] | 156319-0200 | GASKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105681-2490

ME748077 MITSUBISHI

AUTOM. ADVANCE MECHANISM

K 14KL AUTOMATIC TIMER TIMER SPG TIMER

K 14KL AUTOMATIC TIMER TIMER SPG TIMER

Information:

Introduction

The problem identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of faults codes with the DEF Pump, which can lead to an engine derate condition. Affected part numbers for the DEF pumps are:

473-2749 Diesel Exhaust Fluid Pump Gp

473-2750 Diesel Exhaust Fluid Pump Gp

466-8285 Diesel Exhaust Fluid Pump Gp

466-8286 Diesel Exhaust Fluid Pump GpThe codes can be:

Table 1

Event Codes

J1939 Code CDL Code Description

4334-16 E930 (2) Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2)

4334-18 E931 (2) Aftertreatment #1 SCR Dosing Re-agent Absolute Pressure : Low - moderate severity (2)

4374-5 E3118 (6) Aftertreatment #1 Diesel Exhaust Fluid Pump Motor Speed : Current Below Normal

5392-31 E1370 (2) Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime Caterpillar is investigating the root cause of these issues. To support the investigation, Caterpillar is requesting that the following steps are completed, documented, and recorded in SIMSi.Solution

Before starting any troubleshooting, download a Product Status Report (PSR) from the affected engine. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.Follow the appropriate troubleshooting steps for the displayed fault codes. Document the results of the troubleshooting tests in the relevant tables. Refer to Tables 2, 3, and 4.If Troubleshoot requests the Pump and Electronics Unit (PEU) to be replaced, conduct the following inspection before removal of the PEU.

Check the DEF for contamination, if the relevant troubleshooting procedure has not instructed you to do so. Refer to "System Operation Testing and Adjusting", Diesel Exhaust Fluid Quality - Test for the correct procedure.

Inspect the DEF tank cap, DEF header filter, DEF pump filter for any visible obstruction

Illustration 1 g06152768

(1) DEF line in

(2) DEF line out

(3) DEF line out let connection

(4) DEF line inlet connection

(5) Injector DEF line

Inspect and photograph both ends of the DEF fluid lines. If the ends of the lines are damaged or swollen, replace the DEF lines. Refer to "Disassembly and Assembly", Diesel Exhaust Fluid Lines - Remove and Install.At the end of the service take another PSR irrespective of outcome. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.If the troubleshooting steps have required a component to be changed, hold all replaced components for 30 days for a possible Parts Return Request (PRR). Make sure to include the closed work order paperwork.In every instance submit a SIMSi report, complete with TIB number M0079072, CPI number 359775 and submit through the CPI feedback tool within the SIMSi.

Detailed description of symptom experienced and under what conditions issue occurred

Product Status Report (PSR) before and after troubleshooting. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.

Completed Troubleshooting steps tables. Refer to Tables 2, 3, and 4.

Details of DEF tank cap, DEF header filter, DEF pump filter, visual inspection

Photos of DEF fluid lines

Details

The problem identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of faults codes with the DEF Pump, which can lead to an engine derate condition. Affected part numbers for the DEF pumps are:

473-2749 Diesel Exhaust Fluid Pump Gp

473-2750 Diesel Exhaust Fluid Pump Gp

466-8285 Diesel Exhaust Fluid Pump Gp

466-8286 Diesel Exhaust Fluid Pump GpThe codes can be:

Table 1

Event Codes

J1939 Code CDL Code Description

4334-16 E930 (2) Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2)

4334-18 E931 (2) Aftertreatment #1 SCR Dosing Re-agent Absolute Pressure : Low - moderate severity (2)

4374-5 E3118 (6) Aftertreatment #1 Diesel Exhaust Fluid Pump Motor Speed : Current Below Normal

5392-31 E1370 (2) Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime Caterpillar is investigating the root cause of these issues. To support the investigation, Caterpillar is requesting that the following steps are completed, documented, and recorded in SIMSi.Solution

Before starting any troubleshooting, download a Product Status Report (PSR) from the affected engine. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.Follow the appropriate troubleshooting steps for the displayed fault codes. Document the results of the troubleshooting tests in the relevant tables. Refer to Tables 2, 3, and 4.If Troubleshoot requests the Pump and Electronics Unit (PEU) to be replaced, conduct the following inspection before removal of the PEU.

Check the DEF for contamination, if the relevant troubleshooting procedure has not instructed you to do so. Refer to "System Operation Testing and Adjusting", Diesel Exhaust Fluid Quality - Test for the correct procedure.

Inspect the DEF tank cap, DEF header filter, DEF pump filter for any visible obstruction

Illustration 1 g06152768

(1) DEF line in

(2) DEF line out

(3) DEF line out let connection

(4) DEF line inlet connection

(5) Injector DEF line

Inspect and photograph both ends of the DEF fluid lines. If the ends of the lines are damaged or swollen, replace the DEF lines. Refer to "Disassembly and Assembly", Diesel Exhaust Fluid Lines - Remove and Install.At the end of the service take another PSR irrespective of outcome. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.If the troubleshooting steps have required a component to be changed, hold all replaced components for 30 days for a possible Parts Return Request (PRR). Make sure to include the closed work order paperwork.In every instance submit a SIMSi report, complete with TIB number M0079072, CPI number 359775 and submit through the CPI feedback tool within the SIMSi.

Detailed description of symptom experienced and under what conditions issue occurred

Product Status Report (PSR) before and after troubleshooting. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.

Completed Troubleshooting steps tables. Refer to Tables 2, 3, and 4.

Details of DEF tank cap, DEF header filter, DEF pump filter, visual inspection

Photos of DEF fluid lines

Details