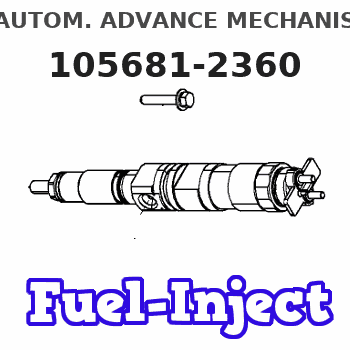

Information autom. advance mechanism

BOSCH

9 420 615 176

9420615176

ZEXEL

105681-2360

1056812360

MITSUBISHI

ME742653

me742653

Rating:

Scheme ###:

| 1. | [1] | 156800-4420 | TIMING-DEVICE HOUSING |

| 2. | [1] | 156801-1700 | FLANGE BUSHING |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 5. | [1] | 156898-0520 | FLYWEIGHT ASSEMBLY |

| 5/1. | [2] | 156802-7420 | FLYWEIGHT |

| 5/1. | [2] | 156802-7420 | FLYWEIGHT |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/4. | [4] | 156896-5500 | COMPRESSION SPRING |

| 5/4. | [4] | 156896-5500 | COMPRESSION SPRING |

| 5/5. | [4] | 156896-5700 | COMPRESSION SPRING |

| 5/5. | [4] | 156896-5700 | COMPRESSION SPRING |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/7. | [2] | 156806-0900 | PIN |

| 5/8/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 5/8/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 5/8/1. | [0] | 156728-0900 | SHIM D19&15T0.3 |

| 5/8/1. | [0] | 156728-1000 | SHIM D19&15T0.5 |

| 5/8/1. | [0] | 156728-1100 | SHIM D19&15T1.0 |

| 5/8/1. | [0] | 156728-2000 | SHIM D19&15T0.4 |

| 5/8/1. | [0] | 156728-2100 | SHIM D19&15T0.7 |

| 5/9/1. | [0] | 156728-1200 | SHIM D14&10.6T0.1 |

| 5/9/1. | [0] | 156728-1300 | SHIM D14&10.6T0.3 |

| 5/9/1. | [0] | 156728-1400 | SHIM D14&10.6T0.5 |

| 5/9/1. | [0] | 156728-1500 | SHIM D14&10.6T1.0 |

| 5/9/1. | [0] | 156728-1500 | SHIM D14&10.6T1.0 |

| 5/9/1. | [0] | 156728-2200 | SHIM D14&10.6T0.4 |

| 5/9/1. | [0] | 156728-2300 | SHIM D14&10.6T0.7 |

| 5/10. | [2] | 156808-0800 | SPACER BUSHING |

| 13. | [1] | 156809-1620 | COVER |

| 13/2. | [1] | 139648-0300 | PACKING RING |

| 13/3. | [1] | 156315-0200 | O-RING |

| 30. | [1] | 156322-0000 | LOCKING WASHER |

| 31. | [1] | 134325-0800 | UNION NUT |

| 33. | [1] | 029331-0190 | GASKET D14&10.2T1 |

| 34. | [1] | 156316-0000 | CAPSULE |

| 35. | [1] | 156314-0600 | CAP |

| 36. | [1] | 156319-0200 | GASKET |

| 37. | [1] | 156914-1500 | PLATE |

| 38. | [2] | 020118-1640 | BLEEDER SCREW |

| 39. | [2] | 014020-8140 | PLAIN WASHER D16&8.5T1.2 |

| 40. | [1] | 479770-8220 | PULSE GENERATOR |

| 40/1. | [1] | 479770-8200 | PULSE GENERATOR |

| 41. | [1] | 139316-0000 | PLAIN WASHER D25&16.5T5 |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Introduction

This Special Instruction addresses the issue about the amount of ash in the DPF, and whether the DPF must be cleaned. Use the following procedure in order to determine if the DPF must be cleaned.Procedure

Note: This test is not designed to determine if a DPF is clean, only to determine if the DPF must be cleaned.

Perform a crack detection test. Refer to Special Instruction, REHS5017. Go to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch). Hold the wire so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 1 g03021156

Top view of DPFView of locations for recording measurements (1) Weld line

Perform Steps 3 through 6 for all locations. Refer to Illustration 1 for the proper location for recording measurements.

Average the measurements and subtract the average from the length of the DPF substrate length. The DPF must be cleaned if the number is more than 6 inches. Replace the DPF if the DPF cannot be cleaned.

This Special Instruction addresses the issue about the amount of ash in the DPF, and whether the DPF must be cleaned. Use the following procedure in order to determine if the DPF must be cleaned.Procedure

Note: This test is not designed to determine if a DPF is clean, only to determine if the DPF must be cleaned.

Perform a crack detection test. Refer to Special Instruction, REHS5017. Go to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch). Hold the wire so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 1 g03021156

Top view of DPFView of locations for recording measurements (1) Weld line

Perform Steps 3 through 6 for all locations. Refer to Illustration 1 for the proper location for recording measurements.

Average the measurements and subtract the average from the length of the DPF substrate length. The DPF must be cleaned if the number is more than 6 inches. Replace the DPF if the DPF cannot be cleaned.