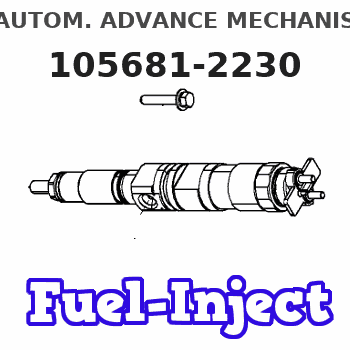

Information autom. advance mechanism

BOSCH

9 420 617 119

9420617119

ZEXEL

105681-2230

1056812230

Rating:

Scheme ###:

| 1. | [1] | 156800-2620 | TIMING-DEVICE HOUSING |

| 2. | [1] | 156801-1500 | FLANGE BUSHING |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 3. | [2] | 156723-0300 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 4. | [2] | 156723-0400 | ECCENTRIC DISC |

| 5. | [1] | 156810-3020 | FLYWEIGHT ASSEMBLY |

| 5/1. | [2] | 156802-0720 | FLYWEIGHT |

| 5/1. | [2] | 156802-0720 | FLYWEIGHT |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/2. | [4] | 156807-1100 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/3. | [4] | 156807-0900 | SLOTTED WASHER |

| 5/4. | [4] | 156805-2900 | COMPRESSION SPRING |

| 5/4. | [4] | 156805-2900 | COMPRESSION SPRING |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/6. | [4] | 156809-0300 | LOCKING WASHER |

| 5/7. | [2] | 156806-0900 | PIN |

| 5/8/1. | [0] | 156728-0800 | SHIM D19&15T0.1 |

| 5/8/1. | [0] | 156728-0900 | SHIM D19&15T0.3 |

| 5/8/1. | [0] | 156728-1000 | SHIM D19&15T0.5 |

| 5/8/1. | [0] | 156728-1100 | SHIM D19&15T1.0 |

| 5/8/1. | [0] | 156728-1100 | SHIM D19&15T1.0 |

| 5/8/1. | [0] | 156728-2000 | SHIM D19&15T0.4 |

| 5/8/1. | [0] | 156728-2100 | SHIM D19&15T0.7 |

| 5/8/1. | [0] | 156728-2400 | SHIM D19&15T0.6 |

| 5/8/1. | [0] | 156728-2500 | SHIM D19&15T0.8 |

| 5/8/1. | [0] | 156728-2600 | SHIM D19&15T0.9 |

| 5/10. | [4] | 156808-0500 | SPACER BUSHING |

| 13. | [1] | 156809-1620 | COVER |

| 13/2. | [1] | 139648-0300 | PACKING RING |

| 13/3. | [1] | 156315-0200 | O-RING |

| 30. | [1] | 156322-0000 | LOCKING WASHER |

| 31. | [1] | 134325-0800 | UNION NUT |

| 33. | [1] | 029331-0190 | GASKET D14&10.2T1 |

| 34. | [1] | 156316-0000 | CAPSULE |

| 35. | [1] | 156314-0600 | CAP |

| 36. | [1] | 156319-0200 | GASKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Introduction

The following special instructions must be used to test for a crack in the Diesel Particulate Filter (DPF). Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information that is contained in this document.Required Tools

Table 1

Required Tools

Part Number Part Name Quantity

380-5200 Tool Kit 1 Testing Procedure

Perform a “Manual Diesel Particulate Filter Regeneration” using Caterpillar Electronic Technician (Cat ® ET).

After the manual DPF regeneration is complete, run the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: Manually set the engine speed to 1800 rpm, the engine must maintain a steady speed for the entire duration of the test.

Illustration 1 g02597531

(1) DPF Outlet Cap

(2) Filter Paper

(3) Hose Assembly

(4) Air Pump

Illustration 2 g02599276

(5) DPF Outlet Port

Hot parts or hot components can cause burns or personal injury. Do not allow hot parts or components to contact your skin. Use protective clothing or protective equipment to protect your skin.

Shut down the engine and remove the Delta P line from the DPF outlet port. Refer to Illustrations 1 and 2.

Illustration 3 g02599418

(6) Filter Paper

Install the filter in the fitting, Refer to Illustration 3. Install the fitting in the DPF outlet port. The filter must be installed in less than 10 minutes after the engine has shut down.

Turn the vacuum pump ON.

Disable automatic regeneration in Cat ET.

Illustration 4 g02597737

Select "Service" - "Configuration" - "Emissions Parameters" and "ARD Manual Disable Status". Select "Disabled". The check engine light and a 3714-31 active code will be present.

Override the "DPF Differential Pressure Line Override" to "Disconnected", using Cat ET. Refer to Illustration 4.

Start the engine. Run the engine at 1800 rpm for 15 minutes.Note: Manually set the engine speed to 1800 rpm, the engine must maintain a steady speed for the entire duration of the test.

Hot parts or hot components can cause burns or personal injury. Do not allow hot parts or components to contact your skin. Use protective clothing or protective equipment to protect your skin.

Shut the engine down and remove the filter holder within 25 minutes. Use proper personal protective equipment to remove the filter holder.

Allow the filter holder time to cool down before disassembly.

Carefully disassemble the filter holder to prevent contamination. Tip the fitting down on a clean surface to remove the filter paper. Handle the filter paper with clean hands and only by the edges.

Illustration 5 g02597796

Compare the stained area in the center of the filter paper to the color coded sheet provided. Refer to Illustration 5.

If the shade is equal to or darker than the "Color Code Sheet", the DPF has a crack or leak. Replace the DPF. Refer to Special Instruction, "Diesel Particulate Filter (DPF) Maintenance on Tier 4 Products Equipped with a Diesel Particulate Filter".

If the shade is lighter than the "Color Code Sheet", then return the unit to service.

Enable the Automatic regeneration in Cat ET.

Select "Service" - "Configuration" - "Emissions Parameters" and "ARD Manual Disable Status". Select "Not - Disabled". The check engine light will go off unless

The following special instructions must be used to test for a crack in the Diesel Particulate Filter (DPF). Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information that is contained in this document.Required Tools

Table 1

Required Tools

Part Number Part Name Quantity

380-5200 Tool Kit 1 Testing Procedure

Perform a “Manual Diesel Particulate Filter Regeneration” using Caterpillar Electronic Technician (Cat ® ET).

After the manual DPF regeneration is complete, run the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: Manually set the engine speed to 1800 rpm, the engine must maintain a steady speed for the entire duration of the test.

Illustration 1 g02597531

(1) DPF Outlet Cap

(2) Filter Paper

(3) Hose Assembly

(4) Air Pump

Illustration 2 g02599276

(5) DPF Outlet Port

Hot parts or hot components can cause burns or personal injury. Do not allow hot parts or components to contact your skin. Use protective clothing or protective equipment to protect your skin.

Shut down the engine and remove the Delta P line from the DPF outlet port. Refer to Illustrations 1 and 2.

Illustration 3 g02599418

(6) Filter Paper

Install the filter in the fitting, Refer to Illustration 3. Install the fitting in the DPF outlet port. The filter must be installed in less than 10 minutes after the engine has shut down.

Turn the vacuum pump ON.

Disable automatic regeneration in Cat ET.

Illustration 4 g02597737

Select "Service" - "Configuration" - "Emissions Parameters" and "ARD Manual Disable Status". Select "Disabled". The check engine light and a 3714-31 active code will be present.

Override the "DPF Differential Pressure Line Override" to "Disconnected", using Cat ET. Refer to Illustration 4.

Start the engine. Run the engine at 1800 rpm for 15 minutes.Note: Manually set the engine speed to 1800 rpm, the engine must maintain a steady speed for the entire duration of the test.

Hot parts or hot components can cause burns or personal injury. Do not allow hot parts or components to contact your skin. Use protective clothing or protective equipment to protect your skin.

Shut the engine down and remove the filter holder within 25 minutes. Use proper personal protective equipment to remove the filter holder.

Allow the filter holder time to cool down before disassembly.

Carefully disassemble the filter holder to prevent contamination. Tip the fitting down on a clean surface to remove the filter paper. Handle the filter paper with clean hands and only by the edges.

Illustration 5 g02597796

Compare the stained area in the center of the filter paper to the color coded sheet provided. Refer to Illustration 5.

If the shade is equal to or darker than the "Color Code Sheet", the DPF has a crack or leak. Replace the DPF. Refer to Special Instruction, "Diesel Particulate Filter (DPF) Maintenance on Tier 4 Products Equipped with a Diesel Particulate Filter".

If the shade is lighter than the "Color Code Sheet", then return the unit to service.

Enable the Automatic regeneration in Cat ET.

Select "Service" - "Configuration" - "Emissions Parameters" and "ARD Manual Disable Status". Select "Not - Disabled". The check engine light will go off unless