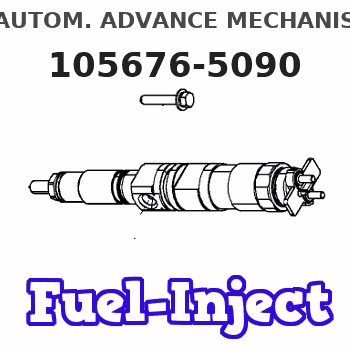

Information autom. advance mechanism

BOSCH

9 420 615 806

9420615806

ZEXEL

105676-5090

1056765090

ISUZU

8971157330

8971157330

Rating:

Scheme ###:

| 1. | [1] | 156700-1301 | FLANGE BUSHING |

| 2. | [1] | 156718-2620 | FLYWEIGHT ASSEMBLY |

| 2/1. | [2] | 156702-7820 | FLYWEIGHT |

| 2/2. | [4] | 156707-0100 | SLOTTED WASHER |

| 2/2. | [4] | 156707-0100 | SLOTTED WASHER |

| 2/3. | [4] | 156707-0000 | SLOTTED WASHER |

| 2/3. | [4] | 156707-0000 | SLOTTED WASHER |

| 2/4. | [4] | 156715-0700 | COMPRESSION SPRING |

| 2/4. | [4] | 156715-0700 | COMPRESSION SPRING |

| 2/5. | [4] | 156709-0200 | LOCKING WASHER |

| 2/5. | [4] | 156709-0200 | LOCKING WASHER |

| 2/6/1. | [0] | 156708-3600 | SHIM D15.5&11.5T0.1 |

| 2/6/1. | [0] | 156708-3700 | SHIM D15.5&11.5T0.2 |

| 2/6/1. | [0] | 156708-3800 | SHIM D15.5&11.5T0.3 |

| 2/6/1. | [0] | 156708-3800 | SHIM D15.5&11.5T0.3 |

| 2/6/1. | [0] | 156708-3900 | SHIM D15.5&11.5T0.4 |

| 2/6/1. | [0] | 156708-4000 | SHIM D15.5&11.5T0.5 |

| 2/6/1. | [0] | 156708-4100 | SHIM D15.5&11.5T0.6 |

| 2/6/1. | [0] | 156708-4200 | SHIM D15.5&11.5T0.7 |

| 2/6/1. | [0] | 156708-4300 | SHIM D15.5&11.5T0.8 |

| 2/6/1. | [0] | 156708-4400 | SHIM D15.5&11.5T0.9 |

| 2/6/1. | [0] | 156708-4500 | SHIM D15.5&11.5T1.0 |

| 2/7. | [2] | 156706-0000 | PIN |

| 8. | [2] | 156703-0500 | ECCENTRIC DISC |

| 8. | [2] | 156703-0500 | ECCENTRIC DISC |

| 9. | [2] | 156703-0600 | ECCENTRIC DISC |

| 9. | [2] | 156703-0600 | ECCENTRIC DISC |

| 11. | [1] | 156701-0620 | FLANGE BUSHING |

| 12/1. | [0] | 156708-2200 | SHIM D46&36.1T0.1 |

| 12/1. | [0] | 156708-2300 | SHIM D46&36.1T0.12 |

| 12/1. | [0] | 156708-2400 | SHIM D46&36.1T0.14 |

| 12/1. | [0] | 156708-2500 | SHIM D46&36.1T0.16 |

| 12/1. | [0] | 156708-2600 | SHIM D46&36.1T0.18 |

| 12/1. | [0] | 156708-2700 | SHIM D46&36.1T0.9 |

| 12/1. | [0] | 156708-2800 | SHIM D46&36.1T1.10 |

| 12/1. | [0] | 156708-2900 | SHIM D46&36.1T1.3 |

| 12/1. | [0] | 156708-3000 | SHIM D46&36.1T1.5 |

| 12/1. | [0] | 156708-3100 | SHIM D46&36.1T1.7 |

| 13/1. | [0] | 156708-2200 | SHIM D46&36.1T0.1 |

| 13/1. | [0] | 156708-2300 | SHIM D46&36.1T0.12 |

| 13/1. | [0] | 156708-2400 | SHIM D46&36.1T0.14 |

| 13/1. | [0] | 156708-2500 | SHIM D46&36.1T0.16 |

| 13/1. | [0] | 156708-2600 | SHIM D46&36.1T0.18 |

| 13/1. | [0] | 156708-2700 | SHIM D46&36.1T0.9 |

| 13/1. | [0] | 156708-2800 | SHIM D46&36.1T1.10 |

| 13/1. | [0] | 156708-2900 | SHIM D46&36.1T1.3 |

| 13/1. | [0] | 156708-3000 | SHIM D46&36.1T1.5 |

| 13/1. | [0] | 156708-3100 | SHIM D46&36.1T1.7 |

| 16. | [1] | 016020-3620 | LOCKING WASHER |

| 17. | [1] | 156709-1000 | LOCKING WASHER |

| 18. | [1] | 131325-2300 | UNION NUT |

| 19. | [1] | 156709-1500 | COVER |

| 20. | [1] | 016020-3620 | LOCKING WASHER |

| 21. | [1] | 156221-4600 | TOOTHED GEAR |

| 22. | [6] | 020006-1670 | BLEEDER SCREW M6P1L16 7T |

Include in #1:

101401-4671

as AUTOM. ADVANCE MECHANIS

Cross reference number

Zexel num

Bosch num

Firm num

Name

105676-5090

8971157330 ISUZU

AUTOM. ADVANCE MECHANISM

K 14KJ AUTOMATIC TIMER TIMER SCDM TIMER

K 14KJ AUTOMATIC TIMER TIMER SCDM TIMER

Information:

Introduction

The problem that is identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is listed below.Problem

A significant amount of HEUI pumps and injectors have been returned, but no cause of failure can be determined.Solution

Diagnostic procedures have been updated and have been incorporated into the following publications:

Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)"

Troubleshooting, "Injection Actuation Pressure - Test"Note: These publications have been translated into Mandarin and Spanish.In addition, a new troubleshooting checklist is included with all service repair for HUEI pumps and HEUI injectors. The checklist is a summary of the diagnostic procedure steps to be confirmed before a suspect component is replaced. The checklist must be completed and returned with the suspect components in order to aid engineering to determine the cause of failure.Following the instructions step-by-step is critical in order to diagnose the failed component correctly. Do not skip steps in the procedures. Skipping steps in the procedure will lead to incorrect diagnosis of the problem.

The problem that is identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is listed below.Problem

A significant amount of HEUI pumps and injectors have been returned, but no cause of failure can be determined.Solution

Diagnostic procedures have been updated and have been incorporated into the following publications:

Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)"

Troubleshooting, "Injection Actuation Pressure - Test"Note: These publications have been translated into Mandarin and Spanish.In addition, a new troubleshooting checklist is included with all service repair for HUEI pumps and HEUI injectors. The checklist is a summary of the diagnostic procedure steps to be confirmed before a suspect component is replaced. The checklist must be completed and returned with the suspect components in order to aid engineering to determine the cause of failure.Following the instructions step-by-step is critical in order to diagnose the failed component correctly. Do not skip steps in the procedures. Skipping steps in the procedure will lead to incorrect diagnosis of the problem.