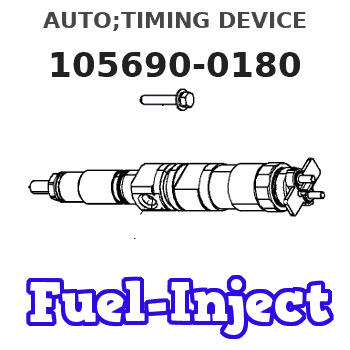

Information auto;timing device

BOSCH

9 420 616 182

9420616182

ZEXEL

105690-0180

1056900180

Rating:

Scheme ###:

| 1. | [1] | 156990-2220 | AUTO;TIMING DEVICE |

| 1/1. | [1] | 156900-2320 | FLANGE BUSHING |

| 1/2. | [1] | 156901-1020 | TIMING-DEVICE HOUSING |

| 1/3. | [2] | 156904-0400 | ECCENTRIC DISC |

| 1/3. | [2] | 156904-0400 | ECCENTRIC DISC |

| 1/4. | [2] | 156904-0500 | ECCENTRIC DISC |

| 1/4. | [2] | 156904-0500 | ECCENTRIC DISC |

| 1/5. | [2] | 156907-1220 | PLATE |

| 1/6. | [2] | 156910-2400 | PIN |

| 1/7. | [4] | 156908-4400 | COMPRESSION SPRING |

| 1/7. | [4] | 156908-4400 | COMPRESSION SPRING |

| 1/8. | [4] | 156909-0300 | SLOTTED WASHER |

| 1/8. | [4] | 156909-0300 | SLOTTED WASHER |

| 1/9. | [4] | 156909-0400 | SLOTTED WASHER |

| 1/9. | [4] | 156909-0400 | SLOTTED WASHER |

| 1/10. | [4] | 156913-7400 | LOCKING WASHER |

| 1/10. | [4] | 156913-7400 | LOCKING WASHER |

| 1/11. | [1] | 156905-0600 | CYLINDER |

| 1/12. | [2] | 156906-0201 | PUMP PLUNGER |

| 1/13. | [2] | 156906-0201 | PUMP PLUNGER |

| 1/14. | [1] | 156902-1020 | COVER |

| 1/14/2. | [1] | 139799-0300 | O-RING |

| 1/14/3. | [1] | 156913-4400 | SPACER RING |

| 1/15. | [6] | 156913-3300 | BLEEDER SCREW |

| 1/16. | [1] | 156913-6520 | TIMING RING |

| 1/17. | [1] | 156911-0600 | BEARING PIN |

| 1/18. | [1] | 011004-0820 | SET OF NUTS |

| 1/20. | [1] | 156912-1900 | TIMING PLATE |

| 1/21. | [3] | 156913-5500 | BLEEDER SCREW |

| 1/35. | [4] | 156913-7900 | SHIM |

| 1/35. | [4] | 156913-7900 | SHIM |

| 2. | [1] | 479749-8502 | PULSE GENERATOR |

| 3. | [1] | 029201-6150 | UNION NUT |

| 4. | [1] | 139316-0000 | PLAIN WASHER D25&16.5T5 |

| 5. | [1] | 156913-6300 | BRACKET |

| 6. | [2] | 010038-1640 | BLEEDER SCREW M8P1.25L16 |

| 7. | [2] | 014130-8140 | CONICAL SPRING WASHER |

| 9. | [1] | 479749-8620 | PULSE GENERATOR |

| 13. | [1] | 156913-4701 | CAPSULE |

| 14. | [1] | 156913-5020 | CAPSULE |

| 14/2. | [1] | 139733-0000 | O-RING |

| 15. | [1] | 025804-1610 | WOODRUFF KEY |

| 16. | [1] | 131325-1800 | UNION NUT |

| 17. | [1] | 029321-4030 | LOCKING WASHER |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105690-0180

9 420 616 182

AUTO;TIMING DEVICE

* K 14KN TIMER V/T TIMER

* K 14KN TIMER V/T TIMER

Information:

Governor Actuator Mounting Replacement:

Removal Of The Previous Assembly

1. Disconnect linkage from cylinder and fuel pump, disassemble bracket from fuel pump lever.2. Remove cylinder from mounting plate, twist out rod end from cylinder.3. Remove mounting plate.Installing Of The New Linkage

1. Install 1433909, 8T4908, 8T4224, 9X6032, 8T4121 Linkage Assembly to engine block.2. Screw in U-joint of 1233885 Cylinder Rod as close as possible, tighten with 1426000 Nut, assemble cylinder with 8T1160 Bolts to the hinge.3. Assemble lever with washer and lock nut (1392085, 8T0389, 1392082, 8T4121), check free movement.4. Disconnect electrical connector from cylinder, turn on ignition, so that cylinder extends.5. Ensure pre-adjustment (overlapping of 1 mm) of U-joint and lever using the 8T4195 Stop Screw; tighten screw with nut (8T4133); See Illustration 2.6. Connect electrical connector to the cylinder and link up rod and lever with the 1233884 Pin.

Illustration 2Calibration

All adjustments have to be done with machine / engine at operating temperature

1. Start the engine.2. Plug-in PDT (portable diagnostic tool), choose menu "PROC" number 5 "ENGINE RPM" and number 6 "RPM DIFFERENCE". High And Low Idle Adjustment At Injection Pump:

1. Actuate the lever of the fuel injection pump by hand and adjust high and low idle by turning the corresponding stop screw at the fuel injection pump. If necessary fix the lever in the high idle position by use of a light spring to make adjustment easier:Set low idle to: 750 Rpm -20/+0 RpmSet high idle to : 2400 Rpm -0/+20 Rpm2. Make sure that when this is set a 1 mm spacer is fitted between the throttle lever and the high idle adjustment screw (see Illustration 3).3. Secure stop screw with locking nut. Seal setting with lockwire and lead seal, use your CAT dealer identification pliers.4. Disconnect electrical connector from the actuator (actuator piston extends completely).5. Stop the engine.6. Assemble and connect the 1413978 or 1397394, 9X8256, 1400277, 6V7743, 5C2890, 1107299, 1396903 Adjustable Rod, use the center hole at the fuel injection pump lever. Make sure that there is no contact between the fuel injection pump lever and the stop screw at high idle position.7. Start the engine.8. Adjust high idle setting with the rod:M312: high idle 2150 Rpm -0/+20 Rpm.M315: high idle 2400 Rpm -0/+20 Rpm.9. Secure the rod with the nuts at the ball joints.10. Mark the lock nut positions at the ball joints with a paint dot or using a felt-tip pen.11. Connect the electrical connector to the actuator.

Illustration 3Calibration/Adjustment Of The Engine

1. Press "F 1" key at the PDT for calibration.2. Choose item number 2 "CALIBRATION".3. Choose item number 1 "SPEED DIAL CAL".4. "MIN POSITION" setting, turn potentiometer on the panel until you receive the minimum voltage shown in the screen, press "ENTER".5. "MAX POSITION" setting, turn potentiometer until you receive maximum voltage shown in the screen, press "ENTER".6. You automatically get back into the previous menu, now choose number 2 "SPEED CAL".7. Change the low idle setting to 1020 Rpm by using the "UP- "or "DOWN-ARROW" keys at the PDT, when finished,

Removal Of The Previous Assembly

1. Disconnect linkage from cylinder and fuel pump, disassemble bracket from fuel pump lever.2. Remove cylinder from mounting plate, twist out rod end from cylinder.3. Remove mounting plate.Installing Of The New Linkage

1. Install 1433909, 8T4908, 8T4224, 9X6032, 8T4121 Linkage Assembly to engine block.2. Screw in U-joint of 1233885 Cylinder Rod as close as possible, tighten with 1426000 Nut, assemble cylinder with 8T1160 Bolts to the hinge.3. Assemble lever with washer and lock nut (1392085, 8T0389, 1392082, 8T4121), check free movement.4. Disconnect electrical connector from cylinder, turn on ignition, so that cylinder extends.5. Ensure pre-adjustment (overlapping of 1 mm) of U-joint and lever using the 8T4195 Stop Screw; tighten screw with nut (8T4133); See Illustration 2.6. Connect electrical connector to the cylinder and link up rod and lever with the 1233884 Pin.

Illustration 2Calibration

All adjustments have to be done with machine / engine at operating temperature

1. Start the engine.2. Plug-in PDT (portable diagnostic tool), choose menu "PROC" number 5 "ENGINE RPM" and number 6 "RPM DIFFERENCE". High And Low Idle Adjustment At Injection Pump:

1. Actuate the lever of the fuel injection pump by hand and adjust high and low idle by turning the corresponding stop screw at the fuel injection pump. If necessary fix the lever in the high idle position by use of a light spring to make adjustment easier:Set low idle to: 750 Rpm -20/+0 RpmSet high idle to : 2400 Rpm -0/+20 Rpm2. Make sure that when this is set a 1 mm spacer is fitted between the throttle lever and the high idle adjustment screw (see Illustration 3).3. Secure stop screw with locking nut. Seal setting with lockwire and lead seal, use your CAT dealer identification pliers.4. Disconnect electrical connector from the actuator (actuator piston extends completely).5. Stop the engine.6. Assemble and connect the 1413978 or 1397394, 9X8256, 1400277, 6V7743, 5C2890, 1107299, 1396903 Adjustable Rod, use the center hole at the fuel injection pump lever. Make sure that there is no contact between the fuel injection pump lever and the stop screw at high idle position.7. Start the engine.8. Adjust high idle setting with the rod:M312: high idle 2150 Rpm -0/+20 Rpm.M315: high idle 2400 Rpm -0/+20 Rpm.9. Secure the rod with the nuts at the ball joints.10. Mark the lock nut positions at the ball joints with a paint dot or using a felt-tip pen.11. Connect the electrical connector to the actuator.

Illustration 3Calibration/Adjustment Of The Engine

1. Press "F 1" key at the PDT for calibration.2. Choose item number 2 "CALIBRATION".3. Choose item number 1 "SPEED DIAL CAL".4. "MIN POSITION" setting, turn potentiometer on the panel until you receive the minimum voltage shown in the screen, press "ENTER".5. "MAX POSITION" setting, turn potentiometer until you receive maximum voltage shown in the screen, press "ENTER".6. You automatically get back into the previous menu, now choose number 2 "SPEED CAL".7. Change the low idle setting to 1020 Rpm by using the "UP- "or "DOWN-ARROW" keys at the PDT, when finished,

Have questions with 105690-0180?

Group cross 105690-0180 ZEXEL

Nissan-Diesel

Isuzu

Nissan-Diesel

105690-0180

9 420 616 182

AUTO;TIMING DEVICE