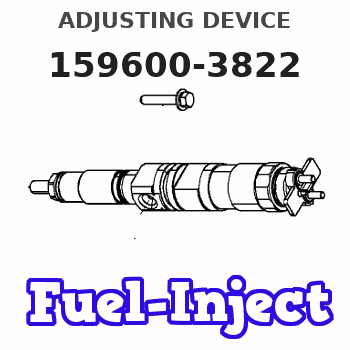

Information adjusting device

BOSCH

9 421 613 635

9421613635

ZEXEL

159600-3822

1596003822

MITSUBISHI

ME741722

me741722

Rating:

Scheme ###:

| 1. | [1] | 159598-2721 | DIAPHRAGM HOUSING |

| 2. | [4] | 159596-2800 | BLEEDER SCREW |

| 3. | [1] | 159596-1200 | SEAL RING |

| 5. | [1] | 131420-0400 | BLEEDER SCREW |

| 6. | [1] | 026506-1040 | GASKET |

| 8. | [2] | 029341-4130 | GASKET |

| 9. | [1] | 139814-0900 | EYE BOLT |

| 15. | [1] | 159604-5620 | ACTUATOR |

| 16. | [1] | 159596-1300 | SEAL RING |

| 17. | [4] | 010206-3040 | HEX-SOCKET-HEAD CAP SCREW |

| 17. | [4] | 010206-3040 | HEX-SOCKET-HEAD CAP SCREW |

| 18. | [4] | 029320-6010 | LOCKING WASHER |

| 18. | [4] | 029320-6010 | LOCKING WASHER |

| 19. | [4] | 139306-0400 | PLAIN WASHER |

| 19. | [4] | 139306-0400 | PLAIN WASHER |

| 30. | [1] | 159597-6901 | BRACKET |

| 31. | [2] | 020106-1440 | BLEEDER SCREW |

| 32. | [4] | 159911-1100 | CLAMPING BAND |

| 33. | [1] | 159597-5000 | CLAMPING BAND |

| 34. | [1] | 020106-0840 | BLEEDER SCREW |

| 35. | [1] | 159900-7100 | TUBE |

| 36. | [1] | 159597-6800 | BRACKET |

| 800S. | [1] | 159595-9201 | COVER |

| 801S. | [1] | 159596-1400 | SEAL RING |

| 802S. | [4] | 010206-3040 | HEX-SOCKET-HEAD CAP SCREW |

| 803S. | [4] | 029320-6010 | LOCKING WASHER |

| 804S. | [1] | 159910-6800 | PLUG HOUSING |

Include in #1:

107691-2373

as _

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Image1.1.1

Image1.1.2

Image1.1.3

Image1.1.4

Image1.1.5

Image1.1.6

Image1.1.7

Image1.1.8

Image1.1.9

PROCEDURES FOR DPF MODULE REWORK

PROCEDURE ( A ) See Image 1.2.1

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( B ) See Image 1.2.2

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( C ) See Image 1.2.3

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( D ) See Image 1.2.4

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( E ) See Image 1.2.5

Butt weld ring flush to retainer ring on inlet assembly in 4 spots.

Fillet weld 2 pins (at 0 and 180 degree orientation) to outlet side of DPF's 300 mm from each other.

Drill 5/8" holes in the outlet assembly flanges 300 mm from each other.

Place tube flush to the flange inside this hole and weld to outlet assembly.

PROCEDURE ( F ) See Image 1.2.6

Position plates (at 0 and 180 degree orientation) to outlet side of the DPF flange.

Allow plates to extend ( minimum 1/4 inch ) past outer edge. Using slots in plates

weld into place.

PROCEDURE ( G ) See Image 1.2.7

Fillet weld (3 mm weld size) 2 pins (at 0 and 180 degree orientation) to outlet side of DPF 260 mm from each other.

Drill a 5/8" hole in the outlet assembly flange 260 mm from each other 13 mm deep.

Place tube flush to the flange inside this hole and weld to outlet assembly.

PROCEDURE ( H ) See Image 1.2.8

Fillet weld 2 pins (at 0 and 180 degree orientation) to outlet side of both DPF's 300 mm from each other.

Drill 5/8" holes in the outlet assembly flanges 300 mm from each other 13 mm deep.

Place tubes flush to the flange inside this hole and weld to outlet assembly.

PROCEDURE ( I ) See Image 1.2.9 and Image 1.2.10

Remove the clamp and gasket from DPF inlet side.

Mate inlet flange to DPF without gasket or clamp.

Tack weld in place.

Apply a continuous weld to the inlet flange/DPF seam.

Image1.2.1

Image1.2.2

Image1.2.3

Image1.2.4

Image1.2.5

Image1.2.6

Image1.2.7

Image1.2.8

Image1.2.9

Image1.2.10

Filter Module Cross Reference Guide See Image 1.3.1.

Image1.3.1