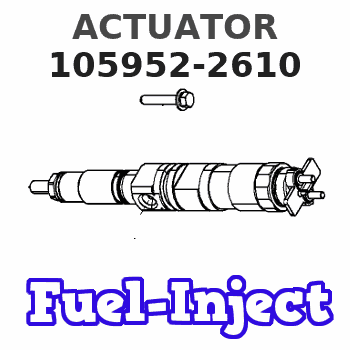

Information actuator

BOSCH

F 019 Z2E 696

f019z2e696

ZEXEL

105952-2610

1059522610

Rating:

Scheme ###:

| 1. | [1] | 159560-0100 | GOVERNOR HOUSING |

| 2. | [8] | 139006-4100 | BLEEDER SCREW |

| 3. | [1] | 029621-7050 | PACKING RING |

| 4. | [1] | 159564-0000 | COILED SPRING |

| 5. | [1] | 159564-4000 | SLOTTED WASHER |

| 6. | [1] | 159564-4100 | SLOTTED WASHER |

| 7. | [1] | 159636-4520 | CONNECTOR |

| 7B. | [1] | 159636-4620 | CONNECTOR |

| 7C. | [1] | 159636-4720 | CONNECTOR |

| 8. | [1] | 020105-1240 | BLEEDER SCREW M5P0.8L12 |

| 11. | [1] | 159579-5620 | ACTUATOR |

| 12. | [2] | 020106-4040 | BLEEDER SCREW |

| 13. | [1] | 159561-0400 | GOVERNOR COVER |

| 14. | [4] | 010006-7040 | BLEEDER SCREW M6P1L70 |

| 15. | [2] | 010006-5540 | BLEEDER SCREW M6P1L55 4T |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 17. | [1] | 154371-5600 | GASKET |

| 18. | [1] | 154390-0400 | GASKET |

| 19. | [1] | 154390-0500 | GASKET |

| 20. | [1] | 155404-3400 | CAP |

| 21. | [1] | 026524-3040 | GASKET |

| 22. | [1] | 029731-4680 | EYE BOLT |

| 23. | [2] | 029341-4130 | GASKET D20&13.8T2* |

| 27. | [2] | 139006-1300 | BLEEDER SCREW M6P1L76 |

| 80. | [1] | 159584-0200 | TOOTHED GEAR |

| 81. | [1] | 014111-2420 | LOCKING WASHER |

| 82. | [1] | 013031-2120 | UNION NUT |

| 83. | [1] | 025803-1310 | WOODRUFF KEY |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106675-4700

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Start By:a. remove oil pumpb. remove oil pan plate 1. Turn the crankshaft until two pistons are at the bottom center. Remove connecting rod caps (1) from the two connecting rods. Remove the lower half of the rod bearing from the rod bearing cap.2. Push the connecting rods away from the crankshaft. Remove the upper half of the rod bearing from the connecting rod. Install the connecting rod bearings dry when the clearance checks are made. Put clean engine oil on the connecting rod bearings for final assembly.3. Install the upper half of the rod bearing in the connecting rod.4. Install the lower half of the rod bearing in the connecting rod cap. Be sure the tabs in the back of the connecting rod bearings are in the tab grooves of the connecting rod and cap. 5. Use Plastigage (A) to check the connecting rod bearing clearance.6. Put Plastigage (A) on the connecting rod bearing.7. Put 2P2506 Thread Lubricant on the threads of the rod bolts and seat surfaces of the nuts.

When connecting rod caps are installed, make sure the number on the side of the cap is next to and respective with the number on the side of the connecting rod.

Do not turn the crankshaft when Plastigage (A) is in position.

Do not use an impact wrench to tighten the nuts the additional 90°.

8. Install connecting rod cap (1). Install the nuts. Tighten the nuts to a torque of 40 4 N m (30 3 lb ft). Put a mark on each nut and the end of each bolt. Tighten the nuts 90° more. Remove the connecting rod caps. Remove Plastigage (A) and measure the width of the Plastigage. The connecting rod clearance must be 0.076 to 0.168 mm (.0030 to .0066 in) for new bearings. The maximum clearance with used bearings is 0.25 mm (.010 in).9. Install the connecting rod caps and tighten the nuts as in Step 8.10. Do Steps 1 through 9 for the remainder of the connecting rod bearings.End By:a. install oil pan plateb. install oil pump

When connecting rod caps are installed, make sure the number on the side of the cap is next to and respective with the number on the side of the connecting rod.

Do not turn the crankshaft when Plastigage (A) is in position.

Do not use an impact wrench to tighten the nuts the additional 90°.

8. Install connecting rod cap (1). Install the nuts. Tighten the nuts to a torque of 40 4 N m (30 3 lb ft). Put a mark on each nut and the end of each bolt. Tighten the nuts 90° more. Remove the connecting rod caps. Remove Plastigage (A) and measure the width of the Plastigage. The connecting rod clearance must be 0.076 to 0.168 mm (.0030 to .0066 in) for new bearings. The maximum clearance with used bearings is 0.25 mm (.010 in).9. Install the connecting rod caps and tighten the nuts as in Step 8.10. Do Steps 1 through 9 for the remainder of the connecting rod bearings.End By:a. install oil pan plateb. install oil pump