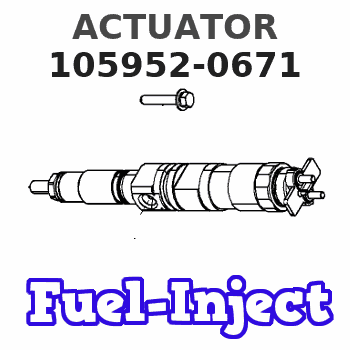

Information actuator

BOSCH

9 420 612 061

9420612061

ZEXEL

105952-0671

1059520671

NISSAN-DIESEL

1910696561

1910696561

Rating:

Scheme ###:

| 1. | [1] | 159560-0100 | GOVERNOR HOUSING |

| 2. | [8] | 139006-4100 | BLEEDER SCREW |

| 3. | [1] | 029621-7050 | PACKING RING |

| 4. | [1] | 159564-5200 | COILED SPRING |

| 5. | [1] | 159564-4000 | SLOTTED WASHER |

| 6. | [1] | 159564-4100 | SLOTTED WASHER |

| 7. | [1] | 159564-7321 | CONNECTOR |

| 8. | [1] | 020105-1240 | BLEEDER SCREW M5P0.8L12 |

| 9. | [1] | 159564-0501 | PLATE |

| 9B. | [1] | 159564-6500 | PLATE |

| 9C. | [1] | 159584-5200 | PLATE |

| 10. | [1] | 020105-1240 | BLEEDER SCREW M5P0.8L12 |

| 11. | [1] | 159567-8322 | ACTUATOR |

| 12. | [2] | 020106-4040 | BLEEDER SCREW |

| 13. | [1] | 159561-1120 | GOVERNOR COVER |

| 14. | [4] | 010006-7040 | BLEEDER SCREW M6P1L70 |

| 15. | [1] | 010006-5540 | BLEEDER SCREW M6P1L55 4T |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 16. | [8] | 014110-6440 | LOCKING WASHER |

| 17. | [1] | 154371-5600 | GASKET |

| 18. | [1] | 154390-0400 | GASKET |

| 19. | [1] | 154390-0500 | GASKET |

| 20. | [1] | 155404-3400 | CAP |

| 21. | [1] | 026524-3040 | GASKET |

| 22. | [1] | 029731-4680 | EYE BOLT |

| 27. | [2] | 139006-1300 | BLEEDER SCREW M6P1L76 |

| 30. | [1] | 159564-2300 | BRACKET |

| 32. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 33. | [1] | 159563-2400 | BLEEDER SCREW |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105952-0671

9 420 612 061

1910696561 NISSAN-DIESEL

ACTUATOR

K

K

Information:

PARTS NEEDED

Qty

Part Number Description

5 2321794 HOSE - INJECTOR LEAK OFF PIPE

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 1% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Refer to the attached Rework Procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-500 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 0.5-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Note: Ensure that all adjustments and repairs that are carried out to the fuel system are performed by authorized personnel that have the correct training. Before beginning ANY work on the fuel system, refer to the Operation and Maintenance Manual, "General Hazard Information" for safety information.

Refer to System Operation, Testing and Adjusting, "Cleanliness of Fuel System Components" for detailed information on the standards of cleanliness that must be observed during ALL work on the fuel system.

Note: Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting. and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Dispose of all fluids according to local regulations and mandates.

Important Notes:

Before attempting any work on the fuel system ensure that the engine is cleaned of any dirt that might contaminate the fuel system. Clean up any spilt fuel before undertaking further work. Check there is adequate clearance around all low pressure lines, and that any clamps are in place and correctly orientated.

No attempt should be made to clean/flush filter elements for re-use. DO NOT PRE-FILL THE FILTERS. Fuel can be hot after engine/machine operation. Care must be taken to ensure hot fuel does not come in contact with exposed skin. Allow engine to cool before undertaking any work.

Fuel Tube Rework Procedure ? Before/After Failure

1. Open/remove the engine cover or hood. Refer to Image1.2.1.

2. View the top of the engine.

3. Identify the 2321794 Injector Leak Off Pipe. Refer to Image1.2.2.

4. Check for a fuel leak around the injector leak off pipe to injector spigot interface.

5. If a fuel leak or residue is present or the pipe shows signs of wear or damage; replace the 232-1794 Injector Leak Off Pipe.

6. Perform a function test to ensure the root cause of the leak has been rectified.

Image1.2.1

Image1.2.2

Have questions with 105952-0671?

Group cross 105952-0671 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Mitsubishi

Nissan-Diesel

105952-0671

9 420 612 061

1910696561

ACTUATOR